2025 Top 10 Precision CNC Machining Trends Revolutionizing Manufacturing Efficiency

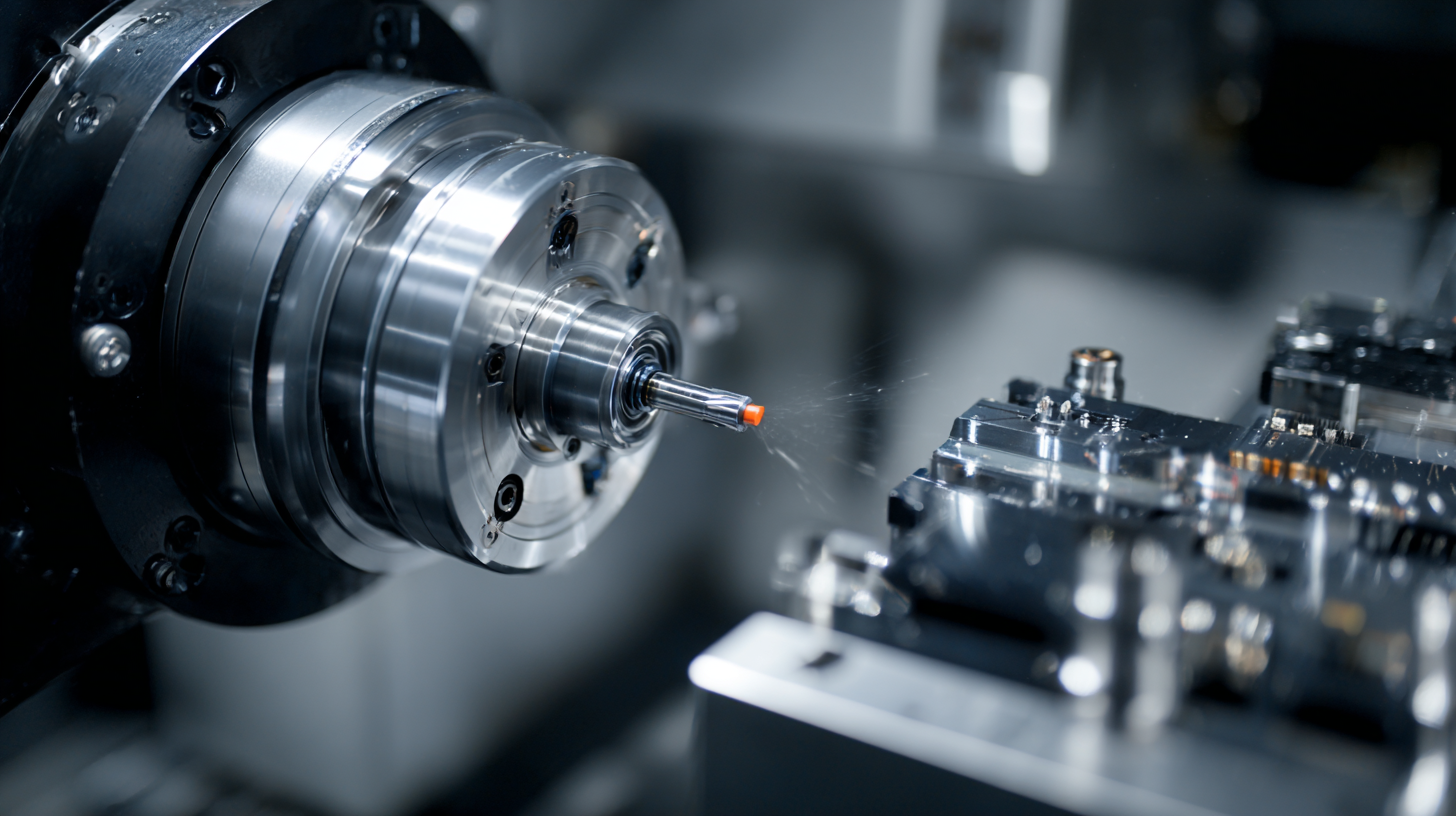

In the rapidly evolving landscape of manufacturing, precision CNC machining has emerged as a cornerstone of modern industrial practices. By employing advanced computer-controlled machines, manufacturers can achieve unparalleled accuracy and efficiency, driving innovation across various sectors. As we look ahead to 2025, several trends are poised to redefine the capabilities of precision CNC machining, enhancing productivity and optimizing production processes. Expert insights from Dr. Sophie Nguyen, a leading authority in the field of precision machining, highlight the importance of these trends: “The future of manufacturing lies in the integration of smart technologies that will empower precision CNC machining to not only meet but exceed industry standards.”

In the rapidly evolving landscape of manufacturing, precision CNC machining has emerged as a cornerstone of modern industrial practices. By employing advanced computer-controlled machines, manufacturers can achieve unparalleled accuracy and efficiency, driving innovation across various sectors. As we look ahead to 2025, several trends are poised to redefine the capabilities of precision CNC machining, enhancing productivity and optimizing production processes. Expert insights from Dr. Sophie Nguyen, a leading authority in the field of precision machining, highlight the importance of these trends: “The future of manufacturing lies in the integration of smart technologies that will empower precision CNC machining to not only meet but exceed industry standards.”

The upcoming decade promises to be transformative, as advancements in automation, artificial intelligence, and materials science converge to elevate the performance of CNC machines. These innovations will not only streamline operations but also unlock new possibilities in design and customization. As Dr. Nguyen notes, "With the implementation of IoT and AI, we can expect CNC machining processes to become more adaptive and responsive, setting a new benchmark for efficiency." As we explore the top 10 trends shaping precision CNC machining, it is clear that the combination of cutting-edge technology and skilled craftsmanship will pave the way for a more efficient and dynamic manufacturing future.

Emerging Technologies Driving Precision CNC Machining Innovations

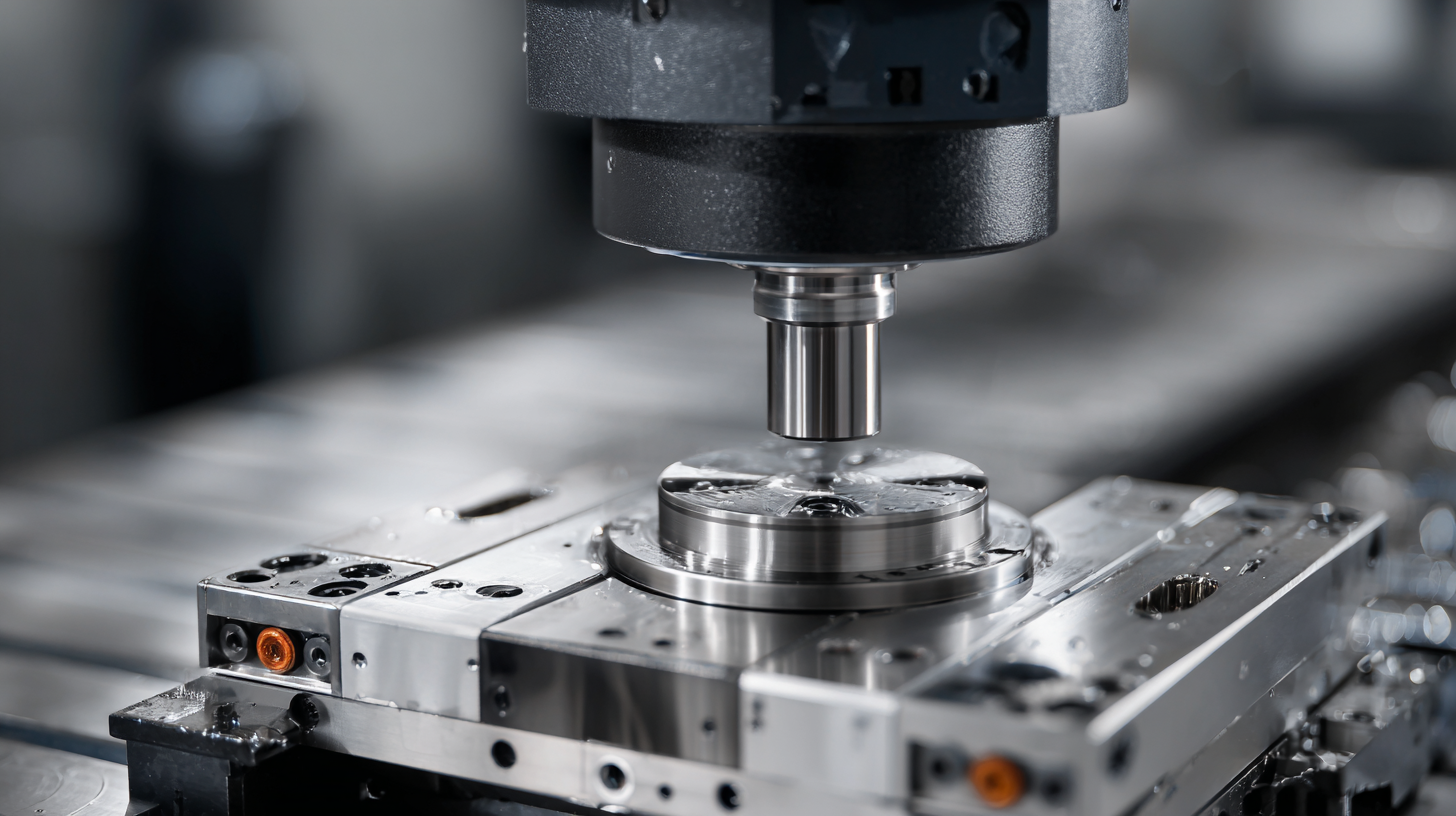

The emergence of new digital manufacturing technologies is transforming precision CNC machining, significantly enhancing productivity across various industries. According to recent reports, the global CNC machine market is expected to reach a market size of $100 billion by 2033, driven by the integration of advanced technologies such as AI and robotics. These innovations are not only improving operational efficiencies but are also reshaping specialized sectors by streamlining processes and minimizing human error.

Companies are increasingly showcasing their advancements at leading expos, highlighting the trend towards sustainability and efficiency. For instance, a recent launch of next-generation CNC routers emphasizes AI-powered features that optimize resource usage, showcasing the industry's commitment to eco-friendly practices. As precision machining evolves, the rise of smart machining tools and cutting technologies is positioning manufacturers to meet the increasing demands of a competitive market, fostering a new era of innovation and productivity in manufacturing.

2025 Top 10 Precision CNC Machining Trends Revolutionizing Manufacturing Efficiency

This chart illustrates the projected growth trends in key areas of precision CNC machining for 2025, highlighting emerging technologies that enhance manufacturing efficiency.

Sustainability Practices Reshaping CNC Manufacturing Processes

Sustainability is becoming an integral focus in the world of CNC machining, driving manufacturers to adopt practices that not only enhance efficiency but also protect the environment. Companies are increasingly investing in energy-efficient machinery and technologies that minimize waste and reduce carbon footprints. This shift is fueled by both regulatory pressures and a growing consumer demand for environmentally responsible products. The implementation of green manufacturing practices helps CNC operations significantly lower operational costs while improving process effectiveness.

Additionally, the adoption of renewable energy sources is gaining traction within the CNC machining industry. Many manufacturers are transitioning to solar, wind, or other sustainable energy systems to power their operations. This change not only contributes to a decrease in greenhouse gas emissions but also enhances the long-term viability of manufacturing facilities. By incorporating such sustainability practices, CNC machining is not only revolutionizing its processes but also playing a critical role in shaping a more responsible and eco-friendly manufacturing landscape for the future.

Integrating AI and Machine Learning for Enhanced Machining Accuracy

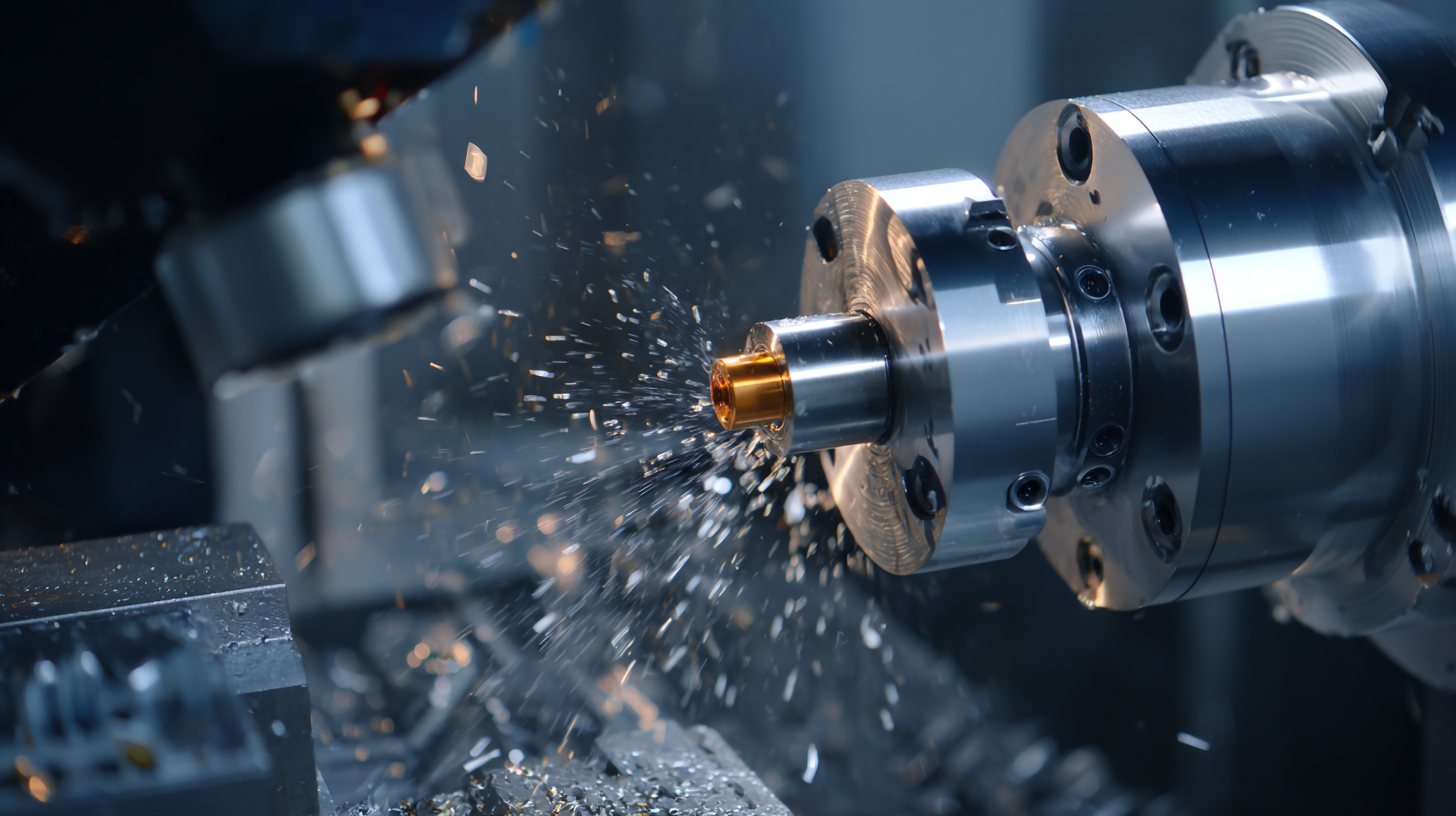

The integration of artificial intelligence (AI) and machine learning in CNC machining is transforming the landscape of manufacturing. Reports indicate that companies adopting these technologies can see productivity improvements of up to 30%. By leveraging advanced algorithms, manufacturers can analyze vast quantities of data in real-time, leading to enhanced machining accuracy and reduced error rates. This marks a significant leap from traditional methods, which often struggle with inefficiencies and inaccuracies.

AI-driven solutions also enable predictive maintenance, helping manufacturers anticipate equipment failures before they occur. Industry studies show that 70% of unplanned downtime can be avoided through effective maintenance strategies, ultimately saving millions in potential losses. Furthermore, the use of deep learning techniques in processes like selective laser cleaning of microbeads allows for more precise removal of contaminants, which was previously challenging with conventional techniques. The shift towards these intelligent systems exemplifies a future where manufacturing becomes smarter, faster, and more efficient.

The Role of IoT in Monitoring and Optimizing CNC Operations

The integration of the Internet of Things (IoT) into CNC machining has become a game-changer for enhancing manufacturing efficiency. By utilizing IoT technologies, manufacturers can monitor CNC operations in real-time, resulting in precise data collection that drives informed decision-making. This level of connectivity allows for the detection of potential issues before they escalate, minimizing downtime and optimizing overall machine performance.

In particular, innovations in diagnostic tools underscore the power of IoT in CNC environments. For instance, advanced charging technology that monitors various parameters can be likened to how IoT systems track CNC machinery metrics. This capability not only enhances the accuracy of operations but also ensures that machines operate at peak efficiency, ultimately leading to cost savings and improved productivity across the manufacturing landscape. The seamless flow of information facilitates a more responsive approach to production challenges, further solidifying the role of IoT as a cornerstone of modern CNC operations.

Advancements in Materials for Enhanced CNC Machining Performance

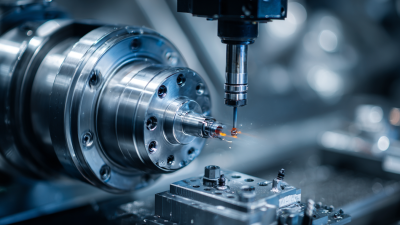

As the manufacturing landscape evolves, advancements in materials are proving to be pivotal in enhancing CNC machining performance. The integration of high-performance materials such as carbon fiber composites, advanced polymers, and specialized alloys is revolutionizing the capabilities of CNC machines. These materials not only reduce weight but also offer superior strength and durability, which translates to more efficient machining processes and longer tool life.

One tip to maximize the benefits of these advanced materials is to optimize tool selection based on material properties. For instance, using cutting tools specifically designed for high-speed machining can lead to better surface finishes and reduced cycle times. Additionally, adapting coolant strategies to accommodate different materials can significantly impact tool performance and workpiece quality.

Investing in training for operators on the unique characteristics of these new materials can also yield substantial efficiency improvements. Familiarity with the properties and machining requirements of advanced materials will empower operators to optimize settings for speed, feed rates, and tool paths, ultimately enhancing the overall productivity of CNC machining operations.

Related Posts

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.