2025 How to Achieve High CNC Machining Precision in Manufacturing

Achieving high CNC machining precision is a crucial element in modern manufacturing, where the demand for exacting tolerances and intricate designs continues to rise. As industries advance and the complexity of parts increases, manufacturers are challenged to maintain superior standards of accuracy. CNC (Computer Numerical Control) technology has revolutionized the manufacturing landscape by enabling automated processes that significantly enhance precision and reduce human error. However, achieving optimal CNC machining precision requires a deep understanding of both machine capabilities and the intricacies of various manufacturing processes.

This article delves into the essential strategies and best practices for maximizing CNC machining precision. It will explore factors such as machine calibration, tool selection, and the importance of material properties, all of which contribute to the end quality of machined components. Furthermore, we will discuss the role of advanced software and technologies in monitoring and enhancing machining processes, ensuring that manufacturers not only meet but exceed industry standards. By focusing on these key areas, organizations can position themselves to thrive in a competitive market that increasingly prioritizes high-quality, precision-engineered products.

Understanding CNC Machining and Its Importance in Precision Manufacturing

CNC machining is a cornerstone of precision manufacturing, leveraging advanced technology to create intricate components with high accuracy. As industries increasingly rely on these processes, understanding the pivotal role of CNC machines becomes essential. The CNC machine market is projected to grow at a compound annual growth rate (CAGR) of 5.5% in the coming years, reflecting a strong demand for precision in various applications. This growth is driven by innovations in AI and IoT, which enhance the capabilities of CNC machines, enabling them to perform complex tasks with greater efficiency.

Tips for achieving high CNC machining precision include regular maintenance of machinery, employing advanced tooling techniques, and optimizing the setup parameters. Utilizing real-time data analytics can significantly improve machining accuracy and reduce waste. Moreover, understanding gear ratios is crucial in optimizing machine performance; as adjustments in gear ratios can lead to enhancements in both productivity and efficiency, ensuring that manufacturing processes remain competitive.

In addition to traditional methods, the integration of nanotechnology in CNC machining is transforming the manufacturing landscape by enabling even finer precision at a microscopic level. By investing in cutting-edge tools and technologies, manufacturers can not only meet but exceed the global demands for high-quality, precision-engineered products. The future of CNC machining is undoubtedly bright, as it adapts to the evolving technological landscape.

Key Factors Affecting CNC Machining Precision in 2025

Achieving high precision in CNC machining in 2025 hinges on understanding key factors that influence manufacturing quality. As the global CNC machine market is anticipated to grow significantly, projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, the demand for high-precision machining centers will continue to rise. According to a report by Technavio, the CNC machine tools market is expected to increase by USD 21.9 billion between 2025 and 2029, driven primarily by advancements in multi-axis machining centers and the incorporation of artificial intelligence. These innovations are crucial as they enhance the ability to produce intricate designs with high accuracy, thereby meeting the escalating requirements of various industries, particularly aerospace and automotive.

Moreover, the integration of next-generation CNC technology is pivotal in improving machining operations. Companies are investing in state-of-the-art CNC equipment that not only automates processes but also elevates precision levels, ensuring reliability in their outputs. As competition intensifies and the manufacturing landscape evolves, organizations must prioritize these technological advancements and adapt their practices to maintain a competitive edge in delivering high-quality products that meet stringent industry standards.

Advanced Tools and Technologies for Enhanced CNC Precision

The manufacturing landscape is witnessing a transformation driven by advanced tools and technologies that enhance CNC machining precision. In recent years, the global CNC tool grinders market has been projected to grow at a CAGR of 6.3% through 2034, reflecting the increasing demand for high-precision tooling across various industries. This growth is fueled by the necessity for more accurate machining capabilities as manufacturers strive for higher quality and efficiency in their production processes.

Additionally, the Grating Ruler Displacement Sensor market is expected to surge to USD 353.26 million by 2033, showcasing the rising need for precision engineering solutions. The adoption of sophisticated displacement sensors plays a crucial role in achieving tight tolerances and accurate measurements, which are critical in modern CNC machining environments. Companies are embracing these technologies not only to improve product quality but also to enhance operational productivity by integrating automation into their manufacturing workflows.

2025 How to Achieve High CNC Machining Precision in Manufacturing

| Technology | Precision Level (μm) | Max Spindle Speed (RPM) | Material Compatibility | Cost ($) |

|---|---|---|---|---|

| Laser-Assisted CNC Machining | 5 | 30,000 | Metal, Plastic | 150,000 |

| 5-Axis CNC Machining | 10 | 25,000 | Aluminum, Titanium | 200,000 |

| High-Speed CNC Machining | 7 | 40,000 | Metal | 180,000 |

| Ultrasonic Machining | 3 | 20,000 | Ceramics, Glass | 220,000 |

| EDM (Electrical Discharge Machining) | 2 | 15,000 | Metal | 250,000 |

Best Practices for Maintaining High Precision in CNC Machining Processes

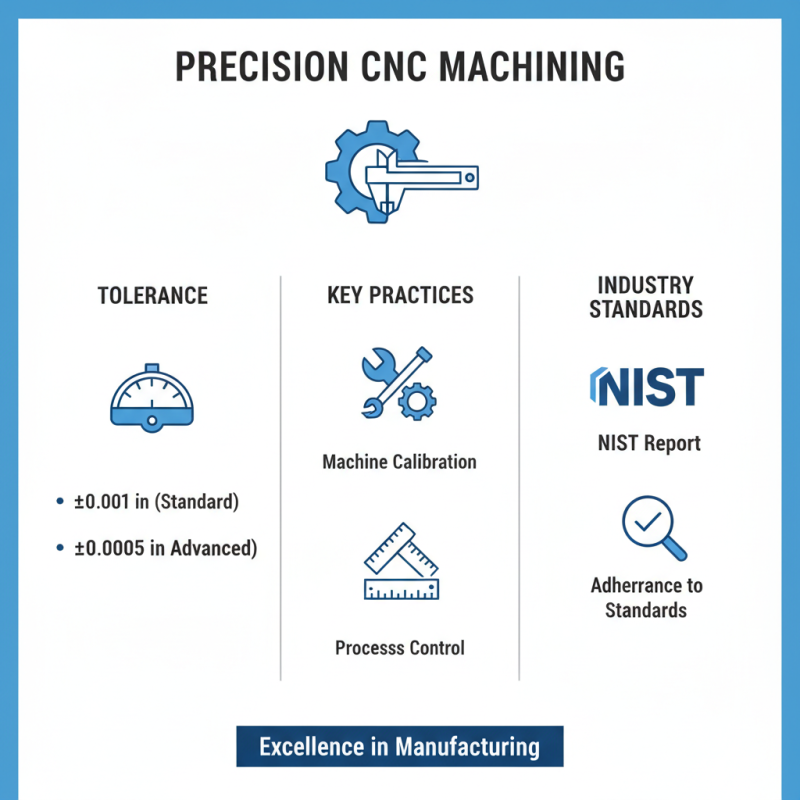

Achieving high precision in CNC machining requires a combination of best practices and adherence to industry standards. According to a report by the National Institute of Standards and Technology (NIST), maintaining a tolerance of ±0.001 inches is essential for high-end CNC components, with many industries now striving for tighter tolerances in the range of ±0.0005 inches. To meet these demands, regular calibration of machines and the use of high-quality cutting tools are critical steps.

Tip: Ensure your CNC machine is calibrated regularly. A routine calibration check can prevent deviations that may lead to production errors and costly rework.

Another vital aspect of maintaining precision is the implementation of consistent workpiece setup and fixturing methods. Utilizing advanced fixtures can significantly reduce variations caused by human error and align workpieces with consistent accuracy. A recent survey indicated that manufacturers who invest in automation and advanced fixturing methods can achieve a productivity increase of up to 30%, enhancing overall precision.

Tip: Invest in advanced workholding solutions. Devices such as zero-point clamping systems can enormously enhance setup speeds and part accuracy, contributing to tighter tolerances in production runs.

Measuring and Ensuring Quality Control in CNC Machining Systems

In the realm of CNC machining, ensuring high precision is increasingly reliant on advanced metrology practices. The integration of automation and artificial intelligence into measurement systems is vital for enhancing manufacturing accuracy. For instance, automated measurement systems can process data in real-time, significantly reducing human error and streamlining quality control processes. As industries evolve, the importance of accurate measurements becomes paramount, driving innovation in both traditional and additive manufacturing.

Moreover, the adoption of automated calibration systems is transforming how CNC manufacturers maintain measurement accuracy. By minimizing reliance on manual processes, these systems enhance operational efficiency and ensure consistent quality. As machine vision inspection continues to advance, driven by AI technologies, manufacturers are better equipped to monitor quality at every stage of production, thus guaranteeing that each machined part adheres to the highest standards of precision and quality assurance. The fusion of metrology with cutting-edge technologies represents a significant leap forward in achieving the precision necessary for modern manufacturing demands.

Related Posts

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.