Top Benefits of Precision Machining in Modern Manufacturing Processes

In today's fast-paced manufacturing landscape, precision machining has emerged as a critical process that significantly enhances efficiency, quality, and overall productivity. According to a report by Industry Research, the global precision machining market is anticipated to reach $100 billion by 2025, driven by increasing demand for high-precision and quality components across various industries, including aerospace, automotive, and medical devices. The ability of precision machining to create intricate parts with minimal tolerances makes it indispensable in modern manufacturing.

As noted by Dr. Emily Zhang, a leading expert in the field of precision machining, "The integration of advanced precision machining techniques allows manufacturers to not only reduce waste but also optimize production cycles, ensuring that every component meets stringent quality standards." This statement underscores the importance of adopting precision machining as a foundational component in manufacturing processes, where the pursuit of perfection and efficiency is paramount.

In summary, the benefits of precision machining are manifold, delivering superior accuracy that translates into enhanced product performance and reliability. As industries continue to seek competitive advantages, embracing precision machining will undoubtedly be a pivotal strategy in achieving operational excellence and fostering innovation.

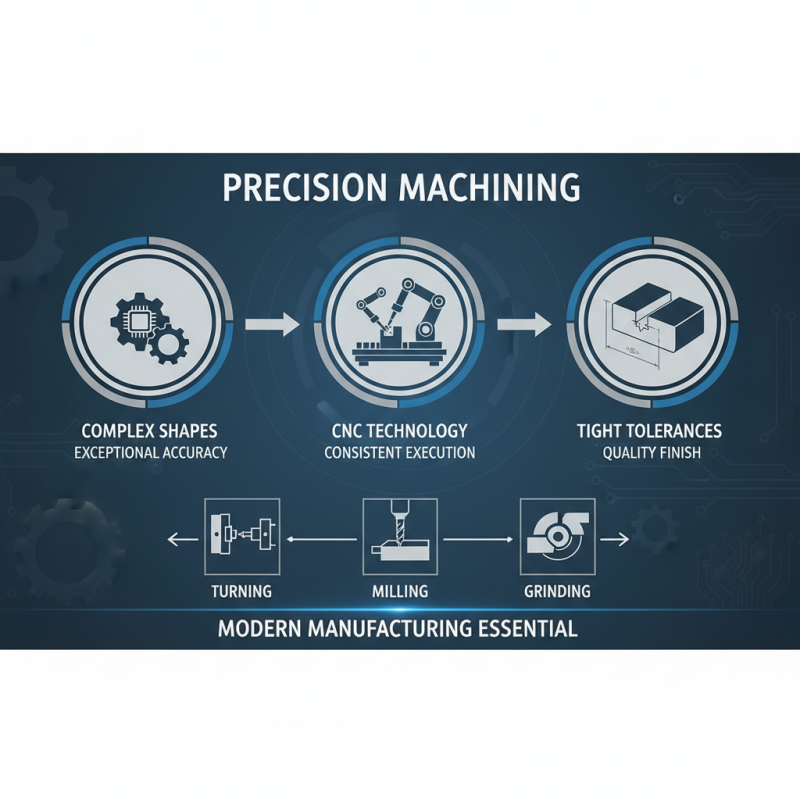

Understanding Precision Machining and Its Role in Manufacturing

Precision machining is a vital component of modern manufacturing processes, characterized by its ability to produce complex shapes and components with exceptional accuracy and efficiency. This specialized form of machining employs advanced technologies such as CNC (Computer Numerical Control) machining, which allows for intricate designs to be executed consistently with a high degree of precision. The process typically involves the removal of material from a workpiece through various methods like turning, milling, and grinding, resulting in finished products that meet stringent specifications and tolerances.

The role of precision machining in manufacturing cannot be overstated, as it directly impacts product quality, production rates, and cost-effectiveness. By ensuring that parts are manufactured to exact dimensions, precision machining minimizes waste and reduces the need for costly reworking or repairs. This reliability not only accelerates the production timeline but also enhances overall operational efficiency, making it a cornerstone in industries ranging from aerospace to automotive. As manufacturers continue to seek competitive advantages in an increasingly demanding market, the implementation of precision machining technologies becomes essential for maintaining high standards and achieving optimal performance in their products.

Key Advantages of Precision Machining in Product Quality Enhancement

Precision machining has become a cornerstone of modern manufacturing, offering significant advantages in product quality enhancement. One of the primary benefits is the ability to achieve tight tolerances. According to a report by the National Institute of Standards and Technology (NIST), precision machining can offer tolerances as tight as ±0.001 mm in certain applications. This level of accuracy is crucial for industries such as aerospace and medical devices, where even the slightest deviation can lead to catastrophic failures or compromised safety.

Another key advantage of precision machining is its contribution to superior surface finishes. The International Journal of Advanced Manufacturing Technology notes that precision machining processes can achieve surface roughness values as low as Ra 0.1 µm. High-quality surface finishes not only improve the aesthetic appeal of products but also enhance their performance and longevity. For instance, a smoother surface reduces friction in mechanical components, leading to lower wear and tear, higher efficiency, and extended product life. This is especially important in sectors where reliability and safety are paramount, making precision machining an indispensable part of modern manufacturing practices.

Impact of Precision Machining on Production Efficiency and Cost Reduction

Precision machining has increasingly become a pivotal component of modern manufacturing processes, particularly when it comes to enhancing production efficiency and reducing costs. According to a report from the National Institute of Standards and Technology (NIST), integrating precision machining in production can increase operational efficiency by up to 30%. This level of efficiency is achieved through enhanced material utilization and reduced waste, which are critical in today's resource-constrained environments. Precision machining allows manufacturers to create components with tighter tolerances, resulting in parts that fit better and function optimally.

Moreover, the ability to minimize scrap rates directly correlates with cost reduction. Data from the American Society of Mechanical Engineers (ASME) indicates that precision machining can reduce scrap rates by as much as 50% compared to traditional machining methods. By producing parts that require less rework and fewer adjustments, manufacturers can save significant amounts on labor costs and raw materials. Consequently, the adoption of precision machining methodologies can lead to faster turnaround times and improved product quality, both of which are essential in maintaining competitiveness in the manufacturing sector.

Top Benefits of Precision Machining in Modern Manufacturing Processes

Applications of Precision Machining Across Various Industries

Precision machining plays a crucial role across various industries, enhancing efficiency and quality in manufacturing processes. In the aerospace sector, for instance, components like turbine blades and structural parts require extreme precision to ensure performance and safety. According to a report by the Aerospace Industries Association, the precision machining market in aerospace is projected to grow at a CAGR of 5.7% from 2021 to 2025. This growth highlights the industry's reliance on advanced machining techniques to produce components that can withstand harsh operating conditions.

In the automotive industry, precision machining is essential for manufacturing high-performance engine components and transmission parts. A study from the International Journal of Automotive Technology indicates that implementing precision machining can reduce material waste by approximately 30%, making the production process not only more efficient but also more sustainable. Moreover, the medical device industry benefits significantly from precision machining, as devices such as surgical instruments and implantable devices require tight tolerances for functionality and patient safety.

Tip: When considering precision machining for your manufacturing needs, evaluate the tolerances and surface finishes required for your specific application. Investing in high-quality equipment and skilled personnel can lead to significant improvements in production efficiency and product reliability. Ensuring that your machining processes are optimized can also minimize waste and reduce overall costs, making precision machining a beneficial strategy across various industries.

Future Trends and Innovations in Precision Machining Technology

The landscape of precision machining technology is continuously evolving, driven by advancements in automation and data analytics. One of the most significant trends is the integration of artificial intelligence and machine learning into machining processes. These technologies enable predictive maintenance, optimizing machine performance, and reducing downtime. As manufacturers adopt smart machining systems, they can analyze data in real time, making immediate adjustments that enhance accuracy and efficiency, ultimately leading to improved product quality.

Furthermore, the rise of additive manufacturing complements traditional precision machining by allowing for the creation of complex geometries that were previously difficult to achieve. This synergy between subtractive and additive methods is paving the way for innovative designs and materials customization. The development of advanced materials, including composites and lightweight alloys, further propels the future of precision machining, making it possible to meet the demands of industries like aerospace and automotive for higher performance and sustainability. The ongoing research in nanotechnology also holds promise, potentially leading to the creation of components with unprecedented precision at the microscopic level.

Related Posts

-

2025 How to Choose Precision CNC Machining for Your Project Needs

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

2025 Top 10 Precision CNC Machining Trends Revolutionizing Manufacturing Efficiency

-

What is CNC Machining Manufacturing and How Does It Benefit Your Business

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

-

10 Essential Tips for Choosing the Right Machine Tool in CNC

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.