2026 Best CNC Machining and Manufacturing Techniques to Consider?

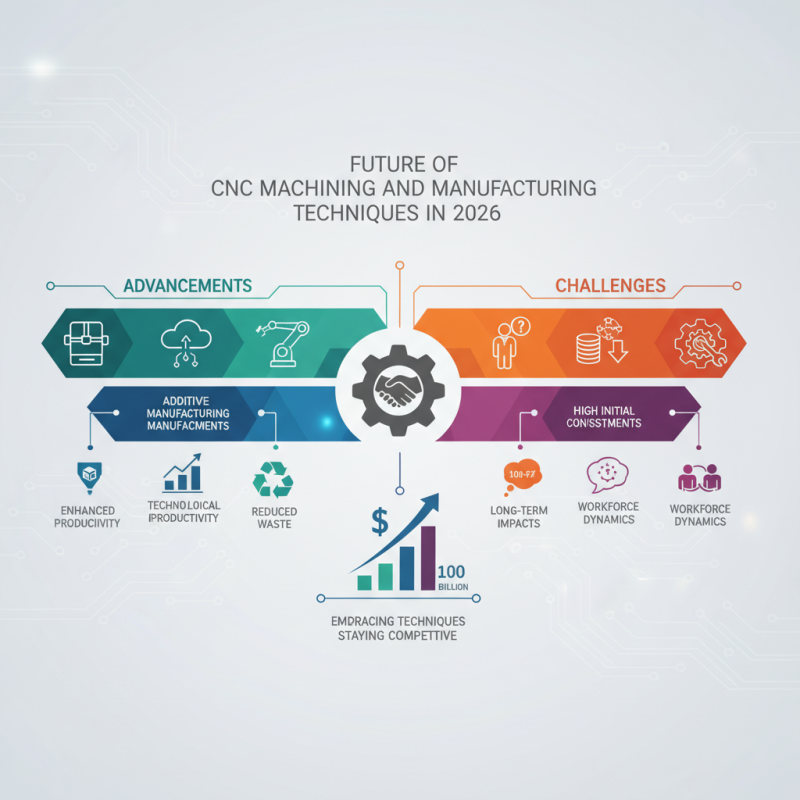

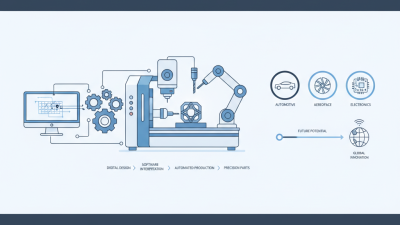

As industries evolve, the need for precise and efficient production methods intensifies. CNC machining and manufacturing techniques have become vital for achieving high-quality results. According to a report by MarketResearchFuture, the global CNC machining market is expected to reach $100 billion by 2026, driven by advancements in technology and rising production demands. This remarkable growth highlights the crucial role of CNC in various sectors.

In the realm of CNC machining and manufacturing, new techniques offer promising solutions. From additive manufacturing to automation, these innovations aim to enhance productivity and reduce waste. However, the integration of these methods is not without challenges. Companies must navigate issues like skill gaps and high initial investments. Additionally, while new technologies present opportunities, they require careful consideration of their long-term impacts on processes and workforce dynamics.

As we reflect on these developments, it becomes clear that embracing CNC machining and manufacturing techniques is essential for staying competitive. The landscape is continuously shifting, and businesses must adapt to thrive. Understanding both the benefits and drawbacks of these advancements will be crucial for future success in the industry.

2026 Overview of CNC Machining Techniques in Manufacturing

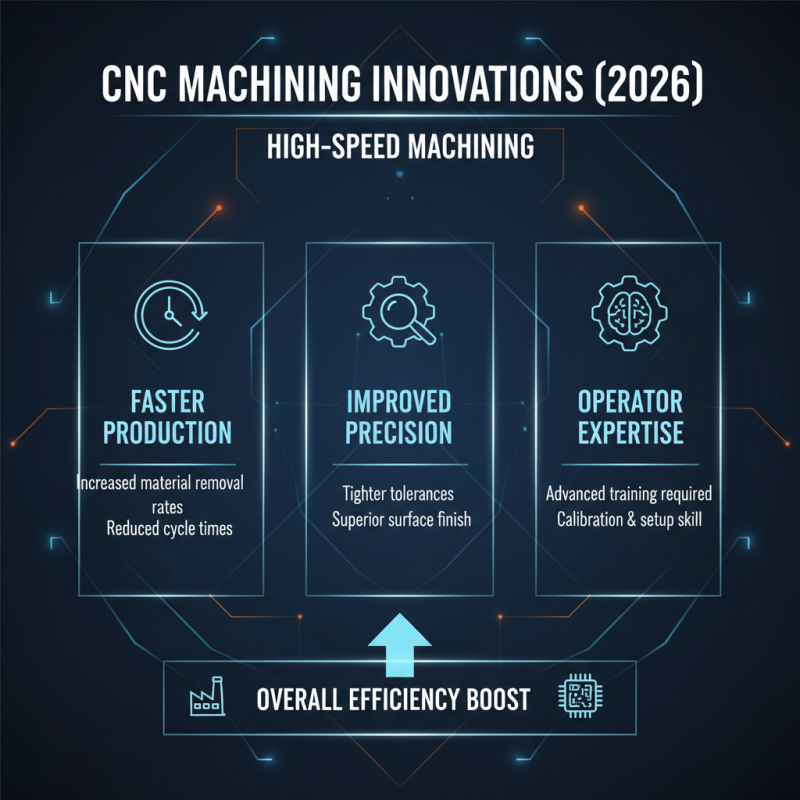

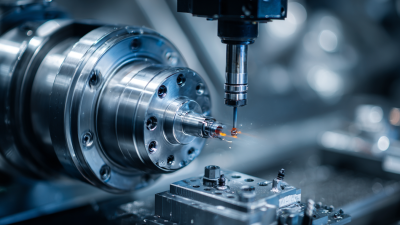

CNC machining has transformed manufacturing processes significantly. In 2026, several techniques stand out. High-speed machining is gaining traction. It allows for faster production with improved precision. This method increases efficiency but requires careful setup and calibration. Operators need to be well-trained for optimal results.

Multi-axis machining is also becoming more popular. It enables intricate designs and complex geometries. This technique can reduce the need for multiple setups. However, it can be challenging to program. It often demands skilled technicians to navigate potential issues. Without proper training, mistakes can occur, impacting production time.

Lastly, additive manufacturing techniques are emerging alongside traditional CNC methods. They create parts layer by layer, using materials like plastic or metal. While this can reduce material waste, the quality of finished products can vary. Consistency is a key concern that manufacturers must address. Balancing these techniques with traditional machining methods can lead to innovative solutions.

Emerging Trends in CNC Machining Efficiency and Precision

Emerging trends in CNC machining focus on enhancing efficiency and precision. Data indicates that manufacturers aiming for high productivity must adopt new technologies. Recent reports show that implementing automation can increase machining speeds by up to 30%. This change leads to faster turnaround times. Yet, not all companies fully embrace these advancements. Some remain hesitant due to initial costs.

Another significant trend is the move towards additive manufacturing techniques. Combining CNC machining and 3D printing can reduce material waste. Studies suggest that this hybrid approach can decrease production costs by around 20%. However, integrating these technologies requires skill and training. Many organizations struggle with the workforce's adaptability to new processes.

Moreover, real-time monitoring systems are gaining traction. These systems improve the accuracy of CNC machines by providing instant feedback. They can reduce errors and scrap rates significantly. But, the reliance on technology can be a double-edged sword. Over-dependence may lead to challenges if systems fail or require updates, emphasizing the need for balance in process optimization.

2026 CNC Machining Efficiency and Precision Metrics

Sustainable Practices in CNC Machining and Manufacturing

In recent years, CNC machining and manufacturing have embraced sustainable practices. These approaches focus on minimizing waste and reducing energy consumption. Machining can be resource-intensive. However, by adopting strategies for efficiency, we can make a difference.

One effective tip is to recycle materials. Metals and plastics can be reused in many processes. It not only cuts costs but also alleviates the burden on landfills. Another crucial practice is to optimize machine run times. Machines should operate at peak efficiency. Inadequate setup can lead to excess energy use and unnecessary wear.

Moreover, considering biodegradable coolants is vital. Traditional coolants can harm the environment. Switching to greener options supports sustainability. Additionally, ensure regular maintenance of machines. Well-maintained equipment operates more efficiently and wastes less power. While the efforts may seem small, they collectively contribute to a more sustainable future in manufacturing.

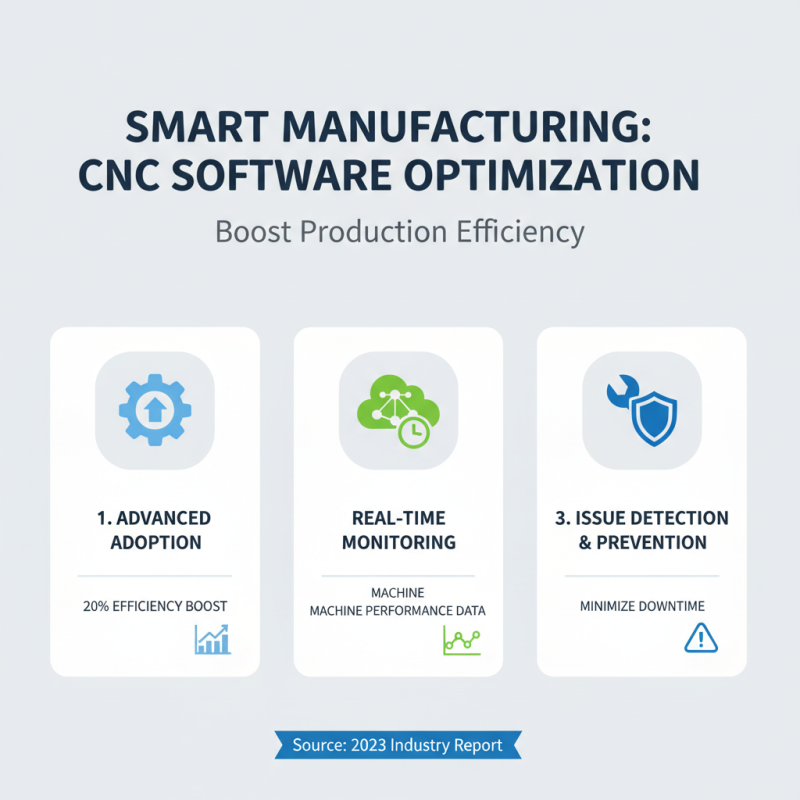

Innovative Software Solutions for CNC Machine Optimization

As manufacturing evolves, innovative software solutions are crucial for optimizing CNC machines. According to a 2023 industry report, companies that adopt advanced software applications see a 20% improvement in production efficiency. This software enables real-time monitoring of machine performance. Operators can quickly identify issues before they escalate.

A significant challenge is the integration of software with existing systems. Many companies struggle with outdated equipment that does not support modern applications. Up to 30% of firms reported difficulties in software compatibility, leading to inefficiencies. Developing a customized solution can be costly and time-consuming. The key is finding balance: optimizing without delivering a perfect product every time.

Data-driven insights are invaluable. Predictive analytics can forecast machine failures, reducing downtime by as much as 18%. However, achieving seamless data integration remains a hurdle. A lack of skilled personnel compounds this issue, making implementation complex. Investing in training can help bridge this gap. A thoughtful approach is required for these practices to be effective.

Future Challenges in CNC Machining and Potential Solutions

CNC machining faces several future challenges. One significant issue is the demand for rapid production and customization. As industries evolve, clients expect quick turnaround times. It pushes manufacturers to adapt. Unfortunately, many CNC machines struggle with handling intricate designs without sacrificing quality.

Another challenge is talent acquisition. Skilled operators are becoming harder to find. Automation can help, but it also raises concerns about job displacement. Companies might need to rethink their training strategies. Upskilling current employees could be more effective than hiring new talent.

Sustainability is yet another area needing attention. The industry often generates significant waste. Innovative approaches to minimize material usage can help. Additionally, focusing on eco-friendly materials may become essential. Such efforts could lead to a more sustainable manufacturing future. Yet, achieving this balance between efficiency and environmental responsibility remains an ongoing struggle for many.

2026 Best CNC Machining and Manufacturing Techniques to Consider

| Technique | Description | Advantages | Challenges | Potential Solutions |

|---|---|---|---|---|

| Additive Manufacturing | 3D printing techniques used for creating complex shapes and designs. | Design freedom, reduced waste, and rapid prototyping. | Material limitations and slower production speeds. | Research in new materials and improving print speeds. |

| Multi-Axis Machining | Machining processes using multiple axes for complex geometries. | Higher precision and the ability to create intricate parts. | Higher machine cost and complexity of operations. | Investing in training for operators and advanced programming software. |

| Automation and Robotics | Use of automated systems for machining processes to increase efficiency. | Improved speed, consistency, and reduction of human error. | High initial investment and need for maintenance. | Leasing equipment and investing in maintenance training. |

| Intelligent Manufacturing | Integration of AI and IoT for smart monitoring and management. | Real-time data analytics for improved decision-making. | Data security concerns and need for skilled personnel. | Implementing robust cybersecurity measures and training staff. |

| Sustainable Manufacturing | Techniques aimed at reducing environmental impact during production. | Lower energy costs and enhanced brand reputation. | Higher upfront costs for sustainable technologies. | Encouraging government incentives and funding for green technologies. |

Related Posts

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

What is CNC Machining Equipment and How Does It Work Explained

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.