Top 10 Best Machine Tools for Precision Engineering in 2023

In 2023, the precision engineering sector continues to evolve rapidly, driven by advancements in technology and increasing demands for accuracy and efficiency. A recent report by MarketsandMarkets estimates that the global machine tools market is projected to grow from $78.16 billion in 2023 to $115.12 billion by 2028, showcasing a compound annual growth rate (CAGR) of 8.20%. This surge underscores the critical role that high-quality machine tools play in various industries, including aerospace, automotive, and electronics, where precision is paramount.

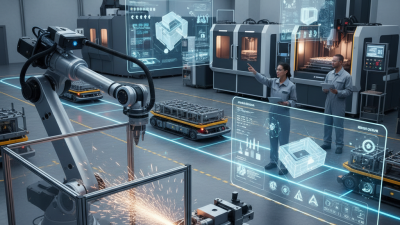

As manufacturers strive for enhanced productivity and reduced operational costs, selecting the right machine tool becomes increasingly essential. The automation trend, coupled with the rise of smart manufacturing, necessitates tools that not only offer the highest accuracy but also integrate seamlessly with advanced technologies such as IoT and AI. The focus on sustainable manufacturing practices also adds layers of complexity, as companies are looking for machine tools that not only deliver precision but also minimize environmental impact.

Understanding the best options available in the market will empower manufacturers to stay competitive and meet modern engineering challenges head-on. In this context, we present the "Top 10 Best Machine Tools for Precision Engineering in 2023," highlighting innovations and performance benchmarks that define excellence in machine tool technology today.

The Importance of Precision in Engineering: Market Insights for 2023

The importance of precision in engineering has become increasingly critical in recent years, especially as industries leverage advanced machine tools to enhance productivity and reliability. According to market analyses, the global CNC machine market is anticipated to grow significantly, projected to rise from $101.22 billion in 2025 to approximately $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This remarkable growth underscores the rising demand for precision engineering solutions that facilitate more efficient manufacturing processes across various sectors.

Additionally, the precision stainless steel market is gaining momentum, with forecasts suggesting a reach of USD 4.1 billion by 2035. The market is expected to display a notable CAGR of 4.3% between 2025 and 2035. This surge is largely driven by the need for reliable materials that can withstand rigorous manufacturing conditions while ensuring high tolerance and accuracy in production. As industries continue to prioritize precision, the adoption of advanced technologies and materials will play a pivotal role in shaping the future of engineering.

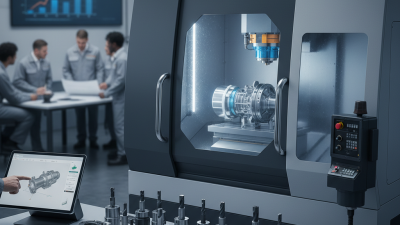

Top Features to Look for in Machine Tools for Precision Engineering

When selecting machine tools for precision engineering, certain key features play a critical role in ensuring that the equipment meets high industry standards. According to a recent report by Allied Market Research, the global precision engineering market is expected to reach $400 billion by 2025, driven largely by advancements in machine tool technology. This underscores the importance of choosing tools that offer high accuracy and reliability. Essential features to consider include robust build quality, advanced CNC capabilities, and precision measurement systems. Tools with closed-loop feedback systems can significantly improve reproducibility, which is critical in applications where tolerances are in the micron range.

Moreover, flexibility and automation are increasingly important in precision engineering. A study by MarketsandMarkets highlights that the automated machine tool market is anticipated to grow at a CAGR of 7.4% from 2020 to 2025, emphasizing the shift towards more adaptable and smart technologies. Features such as predictive maintenance alerts and integration with Industry 4.0 technologies can enhance operational efficiency, minimize downtime, and optimize production processes. As manufacturers continue to seek competitive advantages, investing in machine tools that offer these advanced features will be crucial for meeting the demands of precision engineering in 2023 and beyond.

Top 10 Best Machine Tools for Precision Engineering in 2023

| Machine Tool Type | Max Precision (μm) | Features | Suitable Materials | Price Range ($) |

|---|---|---|---|---|

| CNC Milling Machine | 5 | Multi-axis capability, Automatic tool change | Aluminum, Steel, Plastic | 15,000 - 50,000 |

| Laser Cutting Machine | 10 | High-speed cutting, Fine focus lens | Steel, Wood, Acrylic | 20,000 - 80,000 |

| EDM Machine | 2 | Wire cut and sinker, Low thermal distortion | Titanium, Hard metals | 25,000 - 100,000 |

| 3D Printer (Industrial) | 50 | Additive manufacturing, Material variety | Plastic, Metal, Ceramics | 10,000 - 60,000 |

| Precision Grinder | 1 | High-speed grinding, Compact design | Steel, Carbides | 15,000 - 45,000 |

| Vertical Lathe | 8 | Large turn diameter, High rigidity | Cast iron, Steel | 30,000 - 120,000 |

| Bending Machine | 20 | CNC control, Adjustable bending angle | Sheet metal | 15,000 - 75,000 |

| Milling Cycle | 7 | Dynamic cutting, Low noise | Aluminum, Copper | 10,000 - 40,000 |

| Tapping Machine | 15 | Automatic feeding, High torque | Steel, Aluminum | 5,000 - 25,000 |

| Surface Grinder | 3 | Magnetic chuck, Precision control | Steel, Aluminum | 20,000 - 60,000 |

A Comparative Analysis of the Top 10 Machine Tools: Performance Metrics and User Ratings

In the realm of precision engineering, selecting the right machine tool can significantly impact productivity and the quality of the final product. This comparative analysis evaluates the top 10 machine tools of 2023 based on performance metrics and user ratings. Key performance indicators such as accuracy, speed, and durability were meticulously assessed, providing insights into how each tool meets the rigorous demands of the industry.

User ratings further enrich this comparison, revealing real-world applications and experiences with each machine tool. These ratings highlight not only the tool's effectiveness in various operational contexts but also the level of customer support and ease of use that manufacturers provide. By synthesizing these performance metrics with user feedback, engineers and decision-makers can make informed choices, ensuring they invest in tools that enhance precision and efficiency in their production processes.

Emerging Technologies in Precision Engineering Machine Tools for 2023

In 2023, the landscape of precision engineering machine tools is being significantly shaped by emerging technologies that enhance efficiency and accuracy. One of the foremost advancements is the integration of artificial intelligence (AI) and machine learning algorithms into machine tools. These technologies enable predictive maintenance, reducing downtime and increasing productivity by analyzing operational data to foresee potential failures before they occur.

Additionally, the development of additive manufacturing, particularly in metal 3D printing, is revolutionizing how components are produced in precision engineering. This method allows for complex geometries that traditional machining cannot achieve, leading to lightweight designs that do not compromise durability. As precision engineering continues to embrace these technological innovations, manufacturers are equipped to meet the demands of modern industries, fostering an environment where speed and precision go hand in hand.

Cost-Benefit Analysis of Investing in Advanced Machine Tools for Precision Engineering

Investing in advanced machine tools for precision engineering offers significant cost benefits, particularly as industries aim to enhance their operational efficiencies. According to a recent market research study published by Custom Market Insights, the Global CNC Metal Precision Turned Product Manufacturing Market is expected to reach USD 196.11 billion by 2034, driven by increasing automation and demand for precision components. Companies that adopt high-precision machining technologies stand to gain a competitive edge in producing complex parts with tighter tolerances.

Furthermore, the CNC machine tools market is projected to grow by USD 21.9 billion between 2025 and 2029, largely influenced by the rising demand for multi-axis machining centers. This growth highlights the importance of strategic investments in cutting-edge technology to respond to evolving market demands. Additionally, the electrical discharge machining market is forecasted to grow from $3.316 billion in 2024, reaching an estimated $5.311 billion by 2033, with a compound annual growth rate (CAGR) of 5.4%. These figures underscore the necessity for engineering businesses to continually assess their machinery investments, ensuring they leverage advanced tools that enhance precision and productivity.

Top 10 Best Machine Tools for Precision Engineering in 2023

Related Posts

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

-

10 Essential Tips for Choosing the Right Machine Tool for Your Workshop

-

Top 10 Advancements in Machining Technology You Need to Know About

-

10 Essential Tips for Choosing the Right Machine Tool in CNC

-

Why Machining and Manufacturing Are Crucial for Modern Industrial Success

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.