10 Best Manual Machines for Efficient Work and Precision in Your Projects

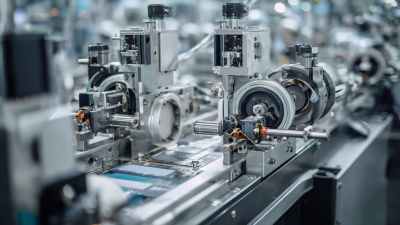

In today's fast-paced manufacturing landscape, the importance of precision and efficiency cannot be overstated. Manual machines, often overshadowed by their automated counterparts, play a crucial role in various industries, particularly in specialized fields where finesse and accuracy are paramount. According to a report by the International Federation of Robotics, the manual machine sector has seen a resurgence, with a 15% increase in demand over the last three years, highlighting their enduring value in craftsmanship and small-scale production.

Expert in the field, Dr. Henry L. Gibbons, a mechanical engineer with over two decades of experience, emphasizes that "manual machines provide a level of control and detail that automation simply cannot replicate.” This sentiment resonates with many artisans and manufacturers who rely on manual machines for intricate tasks such as woodworking, metalworking, and bespoke manufacturing. As industries continue to seek ways to optimize productivity while maintaining high standards of quality, understanding the best manual machines available is essential for professionals invested in their craft.

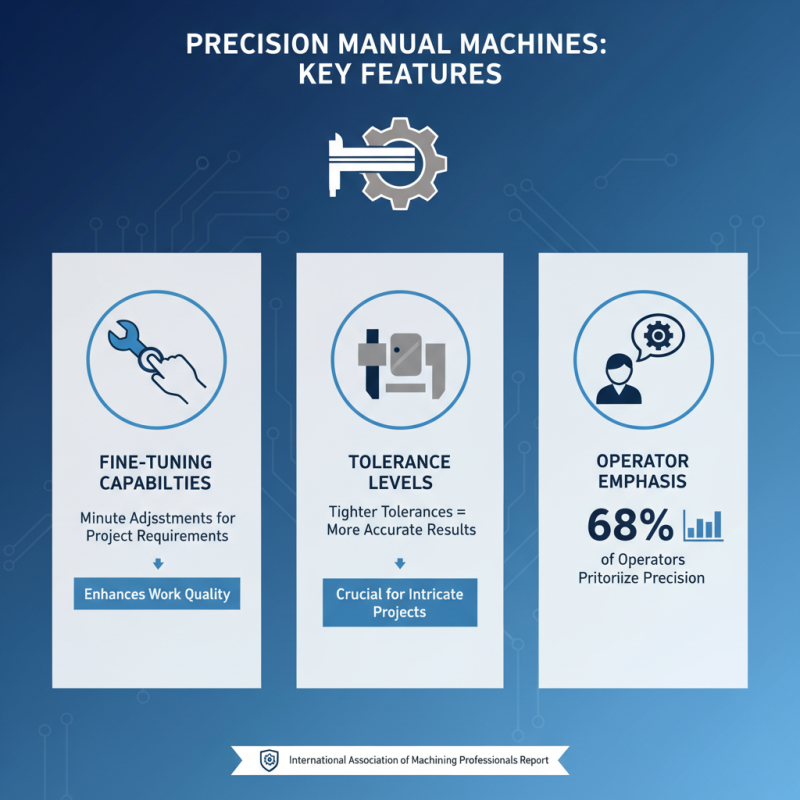

Top Features to Look for in Manual Machines

When selecting manual machines for efficient work and precision, certain features are paramount. According to a report by the International Association of Machining Professionals, approximately 68% of operators emphasize the importance of precision in their tools, as it significantly affects the quality of work produced. Therefore, look for machines that offer fine-tuning capabilities, allowing for minute adjustments that cater to specific project requirements. The precision of a machine is often measured by its tolerance levels; machines with tighter tolerances will generally yield more accurate results, which is crucial for intricate projects.

Another essential feature is ergonomics. A study published in the Journal of Manufacturing Science and Engineering highlights that ergonomic manual machines can reduce operator fatigue by up to 40%, thereby enhancing productivity. Features such as adjustable handles, adequate gripping surfaces, and overall machine weight distribution contribute to a more comfortable working experience. This is particularly significant for projects requiring extended periods of use, as operator comfort translates to sustained focus and better output quality. Additionally, durability should also be a consideration; machines constructed from high-quality materials are more likely to withstand rigorous use and maintain operational integrity over time.

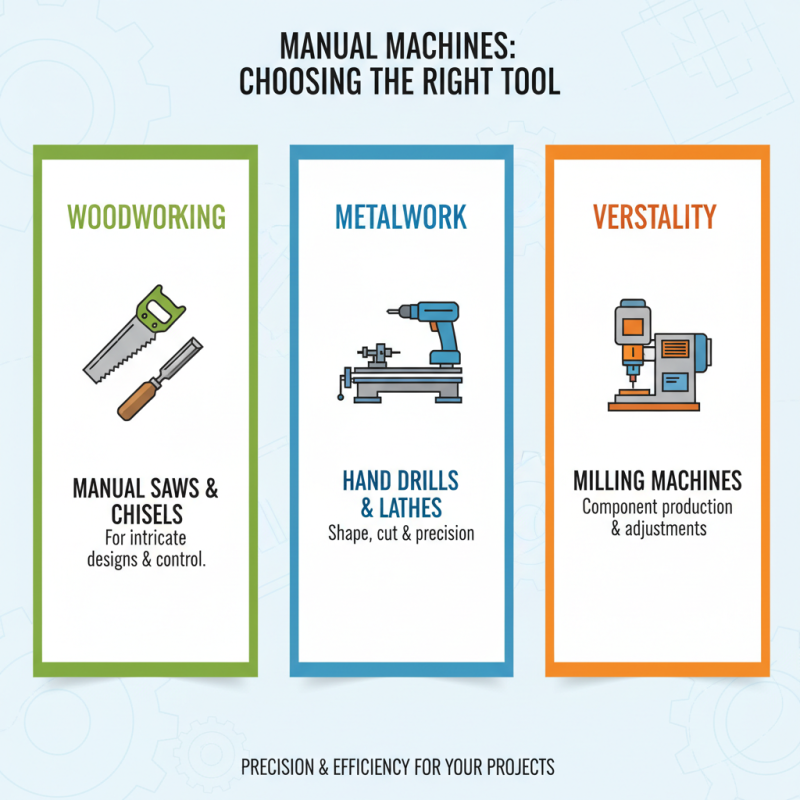

Types of Manual Machines for Various Projects

When it comes to manual machines, understanding the types that best suit your projects is essential for achieving precision and efficiency. Various manual machines cater to distinct tasks, making it crucial to select the right one based on your specific requirements. For woodworking tasks, manual saws and chisels provide the control needed to create intricate designs. Metalwork often demands the use of hand drills and lathes, which can shape and cut materials with precision. Additionally, manual milling machines can offer versatility in producing various components while allowing for hands-on adjustments during fabrication.

Tips for maintaining these machines play a vital role in their effectiveness. Regularly lubricating moving parts can prevent wear and tear, ensuring longevity and performance. Furthermore, always keep your tools organized and store them properly when not in use to avoid damage. This practice not only safeguards your equipment but also enhances your workflow efficiency.

Another important consideration is the ergonomic design of manual machines. When selecting tools, ensure they fit comfortably in your hands to avoid strain during prolonged use. Tools with non-slip grips and adjustable features can make a significant difference in user comfort and precision, ultimately improving the quality of your work.

How to Maintain Your Manual Machines for Longevity

Maintaining your manual machines is crucial for ensuring their longevity and consistent performance in your projects. Regular cleaning is one of the most effective practices to prolong the life of your equipment. After each use, remove dust, debris, or any foreign particles that may accumulate on the machines. Utilizing a soft brush or a vacuum can help keep the surfaces clear without causing scratches or damage. Moreover, periodic lubrication of moving parts is essential to reduce friction, which can lead to wear and tear over time. Be diligent in checking manufacturer guidelines for the correct type of lubricant to use.

Another important aspect of maintenance involves regular inspections. Routinely examining your manual machines for signs of wear, such as rust, loose components, or misalignment, can help you address issues before they escalate into major problems. Ensure that all parts are functioning correctly and replace any worn components promptly. The environment in which you store your machines plays a significant role in their lifespan as well; keep them in a dry, stable area to prevent moisture damage. By adopting these maintenance habits, you can ensure that your manual machines serve you efficiently for many years to come.

Comparing Manual Machines vs. Electric Machines

When it comes to choosing between manual machines and electric machines for your projects, understanding the strengths and weaknesses of each can significantly impact your workflow and output quality. Manual machines offer precision and control that can be unmatched in certain applications. They demand a deeper level of engagement, allowing users to refine their techniques and achieve results tailored to their specific needs. On the other hand, electric machines can enhance efficiency in larger projects, automating tasks and speeding up processes. They are ideal for repetitive tasks where consistency is vital.

**Tips:** When working with manual machines, it’s crucial to maintain focus and practice frequently. Developing muscle memory will not only improve your efficiency but also raise the accuracy of your work. Additionally, always keep your tools well-maintained; routine checks can prevent unexpected malfunctions and ensure a smoother operation.

Investing time in learning how to use both types effectively can broaden your skill set. While manual machines encourage hands-on learning and technical finesse, electric machines can handle bulk tasks quickly. By assessing your project requirements and personal preferences, you can strike a balance that maximizes both precision and productivity.

10 Best Manual Machines for Efficient Work and Precision in Your Projects

| Machine Type | Efficiency Rating | Precision Level | Ease of Use | Versatility |

|---|---|---|---|---|

| Hand Drill | 8/10 | 7/10 | 9/10 | 7/10 |

| Hand Saw | 7/10 | 8/10 | 8/10 | 6/10 |

| Chisel Set | 9/10 | 9/10 | 7/10 | 8/10 |

| Hand Planer | 8/10 | 8/10 | 7/10 | 7/10 |

| Router Plane | 9/10 | 9/10 | 6/10 | 8/10 |

| Screwdriver Set | 8/10 | 7/10 | 9/10 | 8/10 |

| Pliers Set | 7/10 | 6/10 | 8/10 | 9/10 |

| Files and Rasps | 8/10 | 8/10 | 7/10 | 8/10 |

| Brewer's Tap | 7/10 | 6/10 | 7/10 | 6/10 |

| Tweezers | 8/10 | 9/10 | 9/10 | 6/10 |

Best Practices for Using Manual Machines Safely

When working with manual machines, safety should always take precedence. One of the best practices for ensuring safety is to familiarize yourself with the machine’s operation and maintenance guidelines. Each type of manual machine has unique features and potential hazards, so understanding how to properly operate it reduces the risk of accidents. Before starting any project, take the time to review the machine's manual, attend any training sessions if available, and practice using personal protective equipment, such as gloves, goggles, and ear protection.

Additionally, maintaining a tidy workspace is crucial for safe operations. Clutter can lead to mishaps, so ensuring that tools and materials are organized helps prevent accidents. It’s also important to keep the area well-lit and ventilated, allowing for clear visibility of your work and minimizing exposure to harmful fumes from certain materials. Regular inspections of the machines should be conducted to identify any wear or damage that could pose safety risks. Lastly, always be mindful of proper body positioning and techniques to promote ergonomic practices, reducing fatigue and strain while enhancing accuracy in your projects.

Related Posts

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

-

The Future of Precision Machining Innovations Transforming Industry Standards

-

The Future of Machine Manufacturing Innovations Transforming Industries

-

2025 Top 10 Precision CNC Machining Trends Revolutionizing Manufacturing Efficiency

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.