2025 How to Choose Precision CNC Machining for Your Project Needs

In today's rapidly evolving manufacturing landscape, precision CNC machining has emerged as a cornerstone for a myriad of industries, from aerospace to healthcare. According to a recent report by MarketsandMarkets, the CNC machining market is projected to reach USD 100 billion by 2026, reflecting the increasing demand for high precision and efficiency in production processes. As businesses strive for greater operational effectiveness, choosing the right precision CNC machining service becomes imperative for meeting specific project needs and maintaining competitive advantages.

Precision CNC machining offers a level of accuracy and repeatability that is unparalleled in traditional manufacturing methods. Industry data suggests that up to 75% of manufacturers are investing in advanced CNC technologies to enhance precision and reduce waste. With such significant advancements and the rising criteria for customization, understanding how to choose the right precision CNC machining partner is essential. This selection process should consider not only the technical capabilities of the CNC machines but also the expertise of the workforce, materials used, and the overall production environment to ensure that the final products meet stringent quality standards and functional requirements.

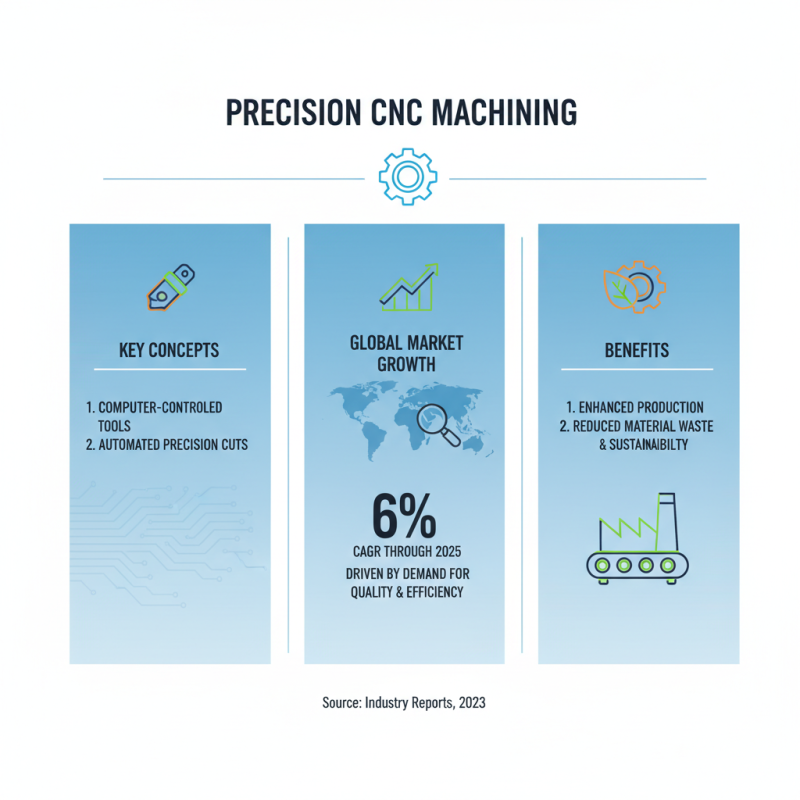

Understanding Precision CNC Machining: Key Concepts and Benefits

When choosing precision CNC machining for your project, it’s essential to grasp the key concepts and benefits that this technology offers. Precision CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computer software to control machine tools for precise cuts and fabrications. Recent industry reports indicate that the global CNC machining market is projected to grow at a CAGR of around 6% through 2025, driven by the rising demand for high-quality and efficient manufacturing processes. This technology not only enhances production efficiency but also reduces material waste, making it an excellent choice for sustainable practices.

One of the primary benefits of precision CNC machining is its ability to produce intricate designs with remarkable accuracy. With tolerances as tight as ±0.001 inches achievable, this form of machining ensures that components fit together perfectly, critical in sectors like aerospace and medical device manufacturing, where failure is not an option. Additionally, CNC machines can operate continuously, optimizing production times and lowering labor costs. According to a report from a leading aerospace manufacturing analyst, firms employing precision CNC machining saw a 15% increase in assembly line efficiency over five years.

**Tips**: When selecting a CNC machining service, consider the supplier's capability with advanced materials and their commitment to quality control measures, such as ISO certification. Ensuring that the provider has experience in your specific industry can further enhance the reliability of the machining process. Always request samples of previous work to gauge their precision standards and surface finishes before making a decision.

Identifying Your Project Requirements for CNC Machining Services

When embarking on a CNC machining project, the first and crucial step is to clearly identify your project requirements. Understanding the specific dimensions, tolerances, and material types you need is essential for achieving precision in the final product. Begin by outlining the design specifications and functional requirements of the part or component you intend to produce. This will facilitate effective communication with potential machining service providers, allowing them to gauge whether they have the capabilities to meet your expectations.

Additionally, consider factors such as production volume, lead times, and budget constraints. The nature of your project—whether it is a one-off prototype or a large batch production—will significantly impact the machining process chosen. Identify whether you need rapid prototyping or long-term manufacturing, as this will influence the choice of materials and technologies employed. By gathering all these details, you can make informed decisions and select the right CNC machining services tailored to your project needs, ensuring a successful outcome.

2025 How to Choose Precision CNC Machining for Your Project Needs

| Project Type | Material Required | Precision Level | Production Volume | Lead Time | Service Options |

|---|---|---|---|---|---|

| Aerospace Components | Aluminum 7075 | ±0.005 inches | Low (1-100 pcs) | 4-6 weeks | Prototype, Low Volume |

| Medical Devices | Titanium | ±0.001 inches | Medium (100-1000 pcs) | 6-8 weeks | Full Service, Quality Control |

| Automotive Parts | Carbon Steel | ±0.01 inches | High (1000+ pcs) | 2-4 weeks | Mass Production, Assembly |

| Electronics Housing | Plastics (ABS) | ±0.02 inches | Variable (1-500 pcs) | 3-5 weeks | Rapid Prototyping, Finishing |

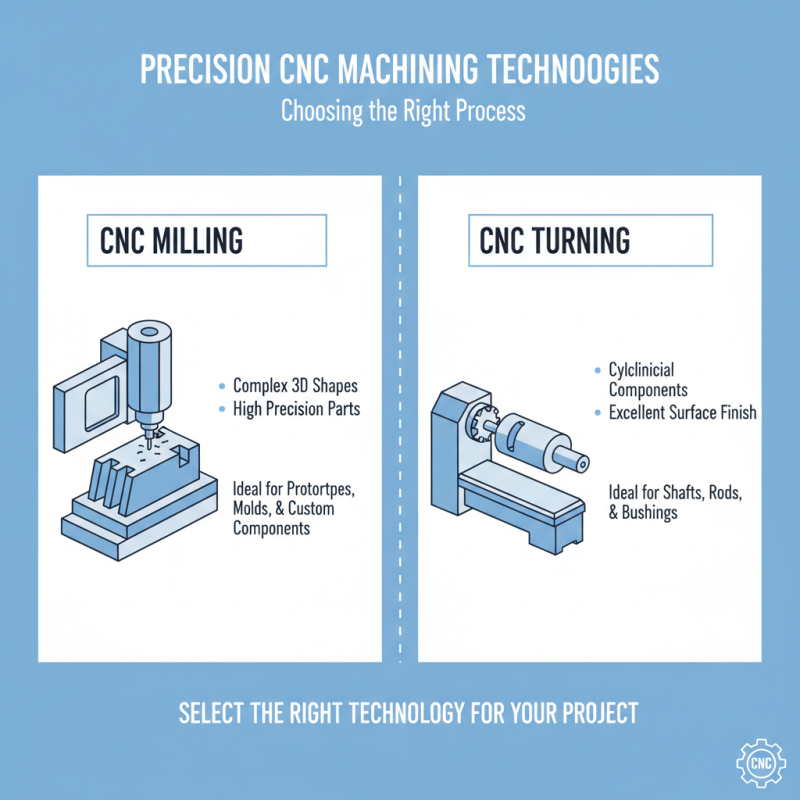

Evaluating CNC Machining Technologies and Their Applications

When choosing precision CNC machining for your project needs, evaluating the various CNC machining technologies available is essential. Each technology offers unique capabilities that can cater to different project specifications. For instance, CNC milling is ideal for creating complex parts with high precision, while CNC turning is best suited for cylindrical components. Understanding these differences allows designers and engineers to select the right machining process that aligns with their manufacturing goals.

Moreover, it's crucial to consider the applications of these technologies in real-world scenarios. Industries such as aerospace, automotive, and medical devices often require specialized machining techniques that ensure accuracy and reliability. For example, additive manufacturing, a growing CNC technology, allows for innovative designs that traditional machining cannot achieve. This versatility not only enhances product development but also streamlines production processes, making it essential for companies to stay updated on technological advancements that could impact their operations.

Selecting the Right CNC Machining Service Provider for Your Needs

Selecting the right CNC machining service provider is crucial for the success of your project. When considering potential partners, it's essential to assess their expertise and experience in the specific type of precision machining you require. Look for providers that have a proven track record in your industry, as this can greatly enhance the likelihood that they will understand your unique needs and challenges. Additionally, reviewing their portfolio or case studies can provide insights into their capabilities and the quality of their work.

Another critical factor to consider is the range of services offered by the provider. CNC machining encompasses various processes, and having a partner who can offer multiple services—such as milling, turning, and electrical discharge machining—can streamline your project. Furthermore, effective communication and customer support are vital throughout the project lifecycle. Ensure that the provider is responsive and willing to collaborate closely to address any concerns or adjustments that may arise during the machining process. By focusing on these key aspects, you can select a CNC machining service provider that aligns perfectly with your project's specifications and goals.

2025 CNC Machining Service Provider Comparison

Cost Considerations and Budgeting for CNC Machining Projects

When planning a CNC machining project, cost considerations can significantly influence your budgeting and overall project success. Understanding the various factors that contribute to CNC machining costs is crucial. These include material selection, complexity of the design, and the machining process required. More intricate designs typically require longer machining times and advanced technologies, which can increase costs. Additionally, high-quality materials may also elevate the overall budget, so it's important to balance quality and affordability.

Tip: Always request multiple quotes from different CNC machining providers to gauge the average market rates for your project. This practice helps you avoid overpaying and provides insight into what additional services may be offered.

Another key element to consider is the potential for unforeseen expenses during the project. Factors such as additional prototypes, adjustments due to design flaws, or shipping can sometimes catch you off guard. Being proactive in your budgeting by setting aside a contingency fund can alleviate financial stress down the road.

Tip: Factor in a contingency budget of 10-20% of your total project costs to cover any unexpected expenses. This approach will make your budgeting process more flexible and secure.

Related Posts

-

2025 Top 10 Precision CNC Machining Trends Revolutionizing Manufacturing Efficiency

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.