How to Choose the Best Precision Machining and Manufacturing Services for Your Business Needs

Choosing the right precision machining and manufacturing services is crucial for the success of any business that relies on high-quality components and efficiency. In a competitive market, precision machining and manufacturing play a pivotal role in determining product quality, cost-effectiveness, and turnaround times. As businesses continue to innovate and demand more customized solutions, selecting the best service provider becomes a critical decision that can impact overall operational performance and customer satisfaction.

When evaluating precision machining and manufacturing services, companies must consider several factors, including the provider's capabilities, technological expertise, and experience in the industry. Understanding the specific requirements of your projects will help narrow down the search for a partner that not only meets but exceeds expectations. This guide aims to provide insights into the top five considerations when choosing a precision machining and manufacturing service, ensuring that your business remains competitive and poised for success in a rapidly evolving landscape. By carefully assessing these factors, you can forge a powerful partnership that enhances productivity and drives growth.

Identifying Your Specific Precision Machining Requirements for Optimal Performance

When selecting precision machining services, the first step involves identifying your specific requirements, which can significantly impact your operational efficiency. According to a report by Mordor Intelligence, the global precision machining market is anticipated to grow at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026, emphasizing the importance of tailored solutions to meet diverse industry demands. It’s essential to consider factors such as tolerances, materials used, and the volume of production required. For instance, industries like aerospace and medical devices often require tolerances as tight as ±0.002 inches, highlighting the need for advanced machining capabilities.

Additionally, understanding the unique performance needs associated with your applications can guide you in choosing a service provider. The 2020 Market Research Report from Research and Markets indicates that the demand for CNC machining in the automotive sector alone is projected to reach $8.38 billion by 2025. This shows that businesses in fast-paced industries need precision machining services that can not only meet stringent specifications but also adapt quickly to changing production demands. Thus, outlining your specific precision machining needs is crucial for selecting a provider that can deliver optimal performance and sustainable growth for your business.

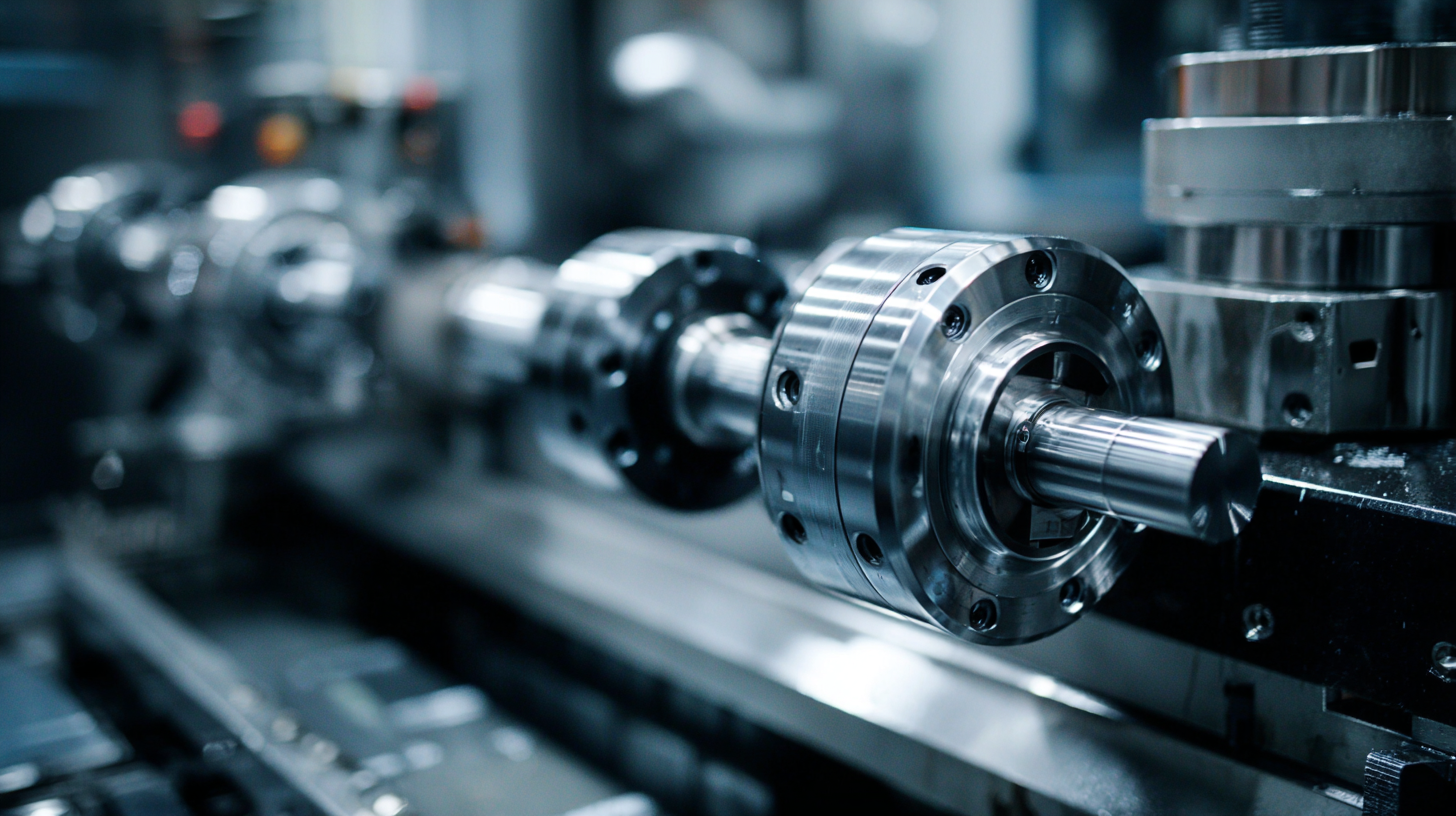

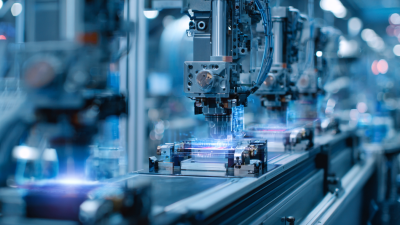

Evaluating the Capabilities and Technologies of Precision Machining Providers

When evaluating the capabilities and technologies of precision machining providers, it’s essential to consider several factors that directly impact the quality of the final products. Precision machining involves subtractive manufacturing processes that require high levels of accuracy and efficiency. According to a recent report by Grand View Research, the global precision machining market is expected to reach $100 billion by 2025, indicating rapid growth and advances in technology. This trend reinforces the importance of selecting a provider equipped with state-of-the-art machinery and skilled personnel who can meet your specific manufacturing needs.

Tips: Always ask potential providers about their machining capabilities, including the types of materials they work with and the tolerances they can achieve. Look for companies that utilize advanced machining technologies such as CNC (Computer Numerical Control) and additive manufacturing techniques. According to Market Research Future, CNC machining alone is predicted to grow at a CAGR of 6.9% between 2018 and 2023, highlighting its significance in precision manufacturing.

In addition to technological capabilities, it’s crucial to assess a provider's quality control processes. Effective quality assurance practices, including ISO certification, ensure that the parts manufactured meet industry standards and client specifications. A study by Quality Digest indicates that companies with robust quality assurance measures reported a 30% reduction in production defects. Thus, integrating quality considerations into your evaluation process can lead to better outcomes and long-term partnerships.

Understanding Industry Standards and Certifications for Quality Assurance

When selecting precision machining and manufacturing services for your business, understanding industry standards and certifications is crucial for ensuring quality assurance. Certifications such as ISO 9001 provide a framework for consistent quality management practices, while industry-specific certifications, like AS9100 for aerospace or IATF 16949 for automotive, emphasize the commitment to high standards in those sectors. These certifications indicate that a company adheres to best practices and is regularly audited for compliance, which can give you confidence in their capabilities.

**Tips:** Look for service providers with first-party certifications and third-party endorsements. This approach not only verifies their compliance with industry standards but also helps you gauge their commitment to continuous improvement. Additionally, inquire about their quality control processes, such as the use of statistical process control (SPC) methods to monitor manufacturing processes and reduce variability.

Another essential factor is the company's experience with specific materials and technologies relevant to your project. Knowing that a manufacturer has successfully completed similar projects can meet your expectations for quality and precision. Always ask for case studies or references that can provide insights into their past performance and adherence to industry standards.

Precision Machining and Manufacturing Services Quality Metrics

Analyzing Cost-Effectiveness and ROI of Precision Manufacturing Services

When selecting precision machining and manufacturing services, businesses must focus on cost-effectiveness and return on investment (ROI) to ensure optimal resource allocation. According to industry reports, precision machining can reduce production costs by up to 30% while improving product quality. This aligns with the increasing demand for real-time data analytics and advancements in machine learning, which enable manufacturers to streamline operations and minimize waste.

Furthermore, investing in advanced precision manufacturing technologies contributes significantly to long-term ROI. A recent study highlighted that organizations adopting precision farming techniques saw a 20% increase in yield due to better data utilization and machine learning applications. As businesses navigate this landscape, it’s essential to choose services that not only meet current needs but also adapt to future technological trends like robotics, which are reshaping supply chain management and logistics, ultimately driving further efficiencies in production processes.

Assessing Supplier Experience and Client Feedback for Reliability and Trustworthiness

When selecting precision machining and manufacturing services, assessing a supplier's experience and client feedback is crucial for ensuring reliability and trustworthiness. One way to gauge a supplier's experience is by examining their portfolio. Look for details about their past projects, industries served, and specific capabilities. A well-rounded supplier will have diverse experiences that align with your business needs.

Additionally, client feedback can provide valuable insights into a supplier's performance and credibility. Seek out reviews and testimonials from previous clients to understand their experiences. Pay attention to comments about product quality, adherence to timelines, and customer service. This information can help you identify suppliers who consistently meet or exceed expectations.

**Tips:** When researching suppliers, consider asking for references and reaching out to those clients for first-hand accounts of their experiences. Also, visit the supplier's facility if possible, as this can give you a direct sense of their operations and quality control practices. Finally, don't hesitate to ask suppliers about their experience with projects similar to yours to ensure they have the relevant expertise.

Related Posts

-

The Future of Precision Machining Innovations Transforming Industry Standards

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

-

The Future of Machine Manufacturing Innovations Transforming Industries

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.