What is CNC Machining Equipment and How Does It Work Explained

CNC machining equipment represents a pivotal advancement in modern manufacturing, facilitating precision and efficiency in the production of complex parts. According to John Smith, a recognized expert in the CNC machining industry, "The evolution of CNC machining equipment has revolutionized how we approach design and production, making it possible to achieve unparalleled accuracy and repeatability." This transformation in machining technology allows manufacturers to streamline their processes while minimizing human error, leading to consistently high-quality outputs.

The functionality of CNC (Computer Numerical Control) machines is rooted in their ability to interpret digital designs and translate them into physical components with remarkable precision. By utilizing various tools and methods, CNC machining equipment automates the cutting, shaping, and finishing of materials such as metals, plastics, and composites. As industries continue to demand higher standards of production, understanding the intricacies of CNC machining equipment becomes essential for engineers and manufacturers striving for innovation and operational excellence.

Furthermore, the integration of advanced software systems with CNC machinery has opened new avenues for design flexibility and customization, empowering businesses to meet the ever-evolving needs of the market. In this exploration of CNC machining equipment, we delve into its working principles, applications, and the future potential it holds for shaping industries worldwide.

What is CNC Machining Equipment: A Comprehensive Overview

CNC (Computer Numerical Control) machining equipment refers to the automated process of operating machine tools through pre-programmed computer software.

Unlike traditional machining methods, which often rely on manual input and control, CNC machines can produce parts and components with high precision and repeatability. This technology is widely used across various industries, including automotive, aerospace, and manufacturing, where accuracy and efficiency are paramount.

When using CNC machining equipment, it is essential to understand its components, including the control system, motors, and machine tools such as lathes and milling machines. The control unit interprets G-code, a programming language that tells the machine how to move and operate. This automation not only improves production rates but also minimizes human error, making CNC machining an invaluable tool in modern manufacturing.

Tips: To maximize the benefits of CNC machining, ensure your design is optimized for CNC processes. This includes minimizing complex geometries that may complicate cutting paths and maximizing the use of standard tooling. Regular maintenance of the machines will also contribute to better performance and extended operational life, reducing unnecessary downtime.

Key Components of CNC Machining Equipment Explained

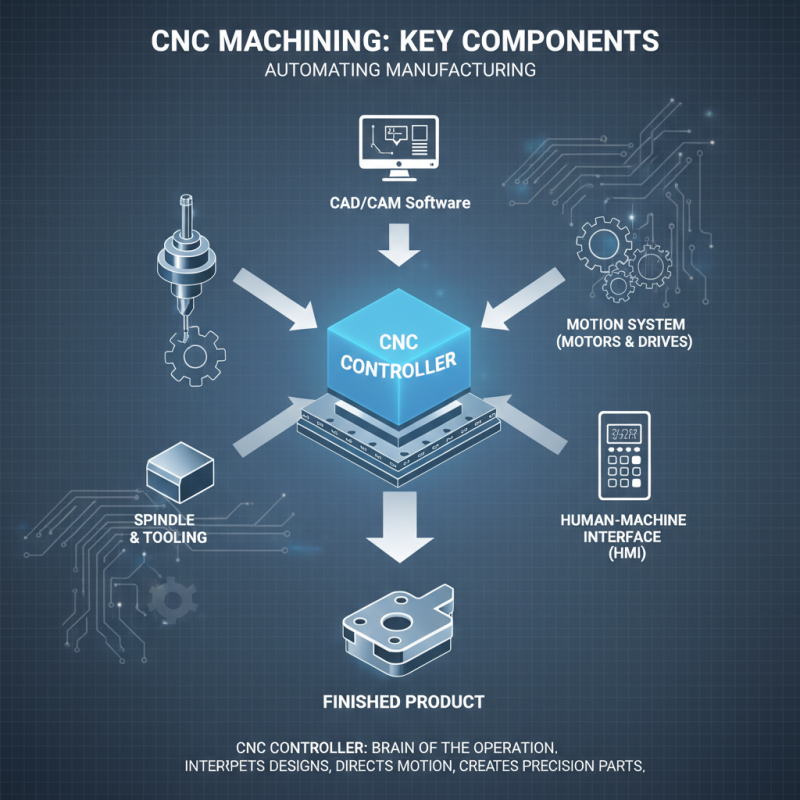

CNC machining equipment consists of several key components that work together to automate the manufacturing process. At the core of the system is the CNC controller, which serves as the brain of the operation. This device interprets the computer-generated design files and converts them into precise movements. The controller sends signals to the machine's moving parts, allowing for accurate adjustments in tool positioning and speed during the machining process.

Another crucial component is the machine tool itself, which can be a milling machine, lathe, or router, depending on the desired operation. These tools are equipped with different attachments and cutting instruments, allowing for a variety of machining tasks, such as drilling, cutting, and shaping materials. Additionally, the workpiece is held in place by a fixture or a vice, ensuring stability and precision as the tool makes contact. Together, these components create an efficient and versatile manufacturing system capable of producing complex parts with high accuracy and repeatability.

The CNC Machining Process: Step-by-Step Workflow

The CNC machining process is a critical operation in modern manufacturing, characterized by its precision and automation. The workflow begins with computer-aided design (CAD) software, where engineers create detailed 3D models of parts to be produced. According to a report by the Global Industry Analysts, the CNC machining market is projected to reach $100 billion by 2026, reflecting the growing reliance on advanced manufacturing techniques that reduce human error and increase production efficiency.

Once the design is complete, the next phase involves importing the CAD model into computer-aided manufacturing (CAM) software. This crucial step translates the digital design into machine instructions known as G-code, which is used by CNC machines to dictate the movements and operations required to create the part. The CNC machine interprets these instructions to perform various tasks, such as cutting, drilling, and milling, with accuracy often within a few thousandths of an inch. Reports indicate that CNC machining can enhance productivity by up to 30% compared to traditional methods. This efficiency gains prominence as industries seek to streamline production lines while maintaining high-quality output.

Following the programming stage, operators set up the CNC machine with the appropriate tools and materials, initiating the machining cycle. This step involves carefully loading the workpiece and calibrating the machine to ensure optimal performance. The machining process is closely monitored, with advanced CNC systems often equipped with sensors for real-time feedback. As noted in industry studies, this integration of smart technologies can significantly reduce downtime and improve overall operational efficiency, reinforcing the trend towards automation in manufacturing environments.

CNC Machining Process: Step-by-Step Workflow

The chart above illustrates the typical workflow of the CNC machining process, highlighting the time spent on each step from design to quality control. Understanding this workflow can help optimize processes in manufacturing environments.

Applications of CNC Machining in Various Industries

CNC machining is a pivotal technology in various industries due to its precision and efficiency in manufacturing components. One of the primary applications can be found in the automotive industry, where CNC machining is employed to create intricate parts such as engine blocks, gears, and custom fittings. The ability to produce these components with exact specifications not only enhances the performance of vehicles but also reduces waste and improves production timelines. Additionally, CNC machining allows for rapid prototyping, enabling engineers to develop and test new designs quickly.

Another significant application of CNC machining is in the aerospace industry. Here, the need for high precision is critical, as even the smallest deviation can lead to safety issues. CNC machines are utilized to manufacture complex components such as turbine blades and structural members of aircraft. The automation of processes ensures that these components meet stringent regulatory standards while optimizing performance. Furthermore, industries such as medical device manufacturing also heavily rely on CNC machining to create customized prosthetics and surgical instruments, highlighting the versatility and essential nature of this technology across diverse fields.

Benefits of Using CNC Machining Equipment in Manufacturing

CNC machining equipment has revolutionized the manufacturing landscape by providing precision, efficiency, and versatility. One of the most significant benefits of using CNC (Computer Numerical Control) machining equipment is its ability to produce complex parts with high accuracy consistently. According to a recent industry report from the International Organization for Standardization (ISO), companies utilizing CNC machining report a 30% increase in production efficiency due to reduced manual errors and enhanced automation in their processes.

Moreover, CNC machining allows for significant material savings, as the machinery can maximize yield from raw materials while minimizing waste. A survey conducted by the Manufacturing Institute found that organizations that implemented CNC technology saw an average 25% reduction in material costs. This translates not only to financial savings but also contributes to more sustainable manufacturing practices by lessening the environmental impact of material waste.

Tip: When considering implementing CNC machining in your operations, it's essential to invest in training for your staff. A well-trained team can maximize the machine's capabilities, which is crucial for achieving the best results.

Additionally, CNC machining equipment supports a wide range of materials, from metals to plastics, making it adaptable for various industries. Companies can quickly pivot and adjust their production lines to cater to different product demands without significant downtime, as indicated in a report by the National Association of Manufacturers, which noted that businesses with CNC capabilities can respond to market changes at a 40% faster rate than those reliant on traditional machining methods.

Tip: Regular maintenance of CNC equipment can extend its lifespan and maintain performance standards. Schedule routine check-ups to ensure that your machines are operating at their best, thus maximizing your investment and productivity.

CNC Machining Equipment and Its Benefits

| Feature | Description | Benefit |

|---|---|---|

| Precision | CNC machines can produce highly precise components. | Increased quality and reduced waste in manufacturing processes. |

| Automation | Processes are computer-controlled, reducing manual labor. | Higher efficiency and consistency in production. |

| Versatility | CNC machines can work with a variety of materials. | Ability to manufacture diverse products from plastic to metal. |

| Repeatability | CNC machines can produce multiple identical items. | Consistent product quality across large production runs. |

| Speed | CNC machining is faster than traditional machining methods. | Reduced lead times and improved production rates. |

Related Posts

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

2025 How to Achieve High CNC Machining Precision in Manufacturing

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Top 10 CNC Machine Tools Every Engineer Should Know in 2023

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.