Top CNC Machining Equipment Trends to Watch for in 2025

As we look ahead to 2025, the landscape of CNC machining equipment is poised for transformative changes driven by technological advancement and industrial demands. Renowned expert in the field, Dr. Emily Zhang, a leading authority on manufacturing technology, emphasizes the significance of these developments by stating, "The future of CNC machining equipment lies in intelligent automation and enhanced connectivity." This statement encapsulates the prevailing trends that are likely to define the industry in the coming years.

With the increasing complexity of manufacturing processes, CNC machining equipment is expected to evolve towards greater efficiency and precision. Innovations such as advanced software integration, real-time data analytics, and smart manufacturing solutions are becoming focal points that promise to enhance productivity and reduce operational costs. As industries strive for sustainability, the push for more eco-friendly CNC machining practices is anticipated to gain momentum, making it crucial for businesses to adapt and innovate.

In summary, the CNC machining equipment sector is on the brink of significant evolution, influenced by technological advancements and changing market needs. Experts predict that staying ahead of these trends will not only empower manufacturers to optimize their operations but also place them strategically within a competitive landscape. As we explore these trends further, we uncover the insights that will shape the future of CNC machining equipment.

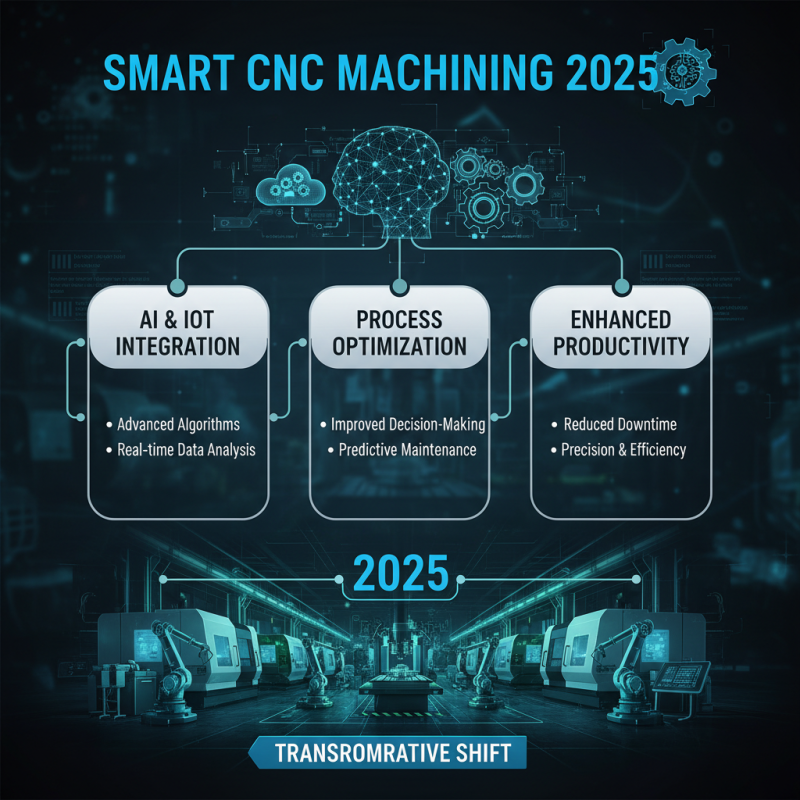

Emergence of Smart CNC Machining Technologies in 2025

The landscape of CNC machining is poised for a transformative shift with the emergence of smart CNC machining technologies in 2025. As industries increasingly seek efficiency and precision, the integration of advanced technologies such as artificial intelligence and the Internet of Things (IoT) is set to revolutionize traditional machining processes. These technologies will enable machines to analyze performance data in real-time, leading to improved decision-making and predictive maintenance. The ability to detect anomalies and adjust operations proactively will significantly reduce downtime and enhance productivity.

Moreover, the emergence of smart CNC machining will foster a more collaborative approach to manufacturing. With machine learning algorithms, CNC machines will be capable of learning from past operations, leading to optimized cutting paths and reduced material waste. This self-optimization not only boosts productivity but also contributes to sustainable manufacturing practices. As manufacturers adopt these smart technologies, they will also see a shift toward more user-friendly interfaces, allowing operators of varying skill levels to maximize machine potential, thereby democratizing access to advanced machining capabilities. The future of CNC machining is not just about maintaining efficiency, but also about embracing intelligent solutions that drive innovation across the manufacturing sector.

Advancements in CNC Machine Automation and Robotics

As we approach 2025, the CNC machining landscape is set to undergo significant transformations, particularly in the realms of automation and robotics. The rise of advanced CNC machine automation is driven by the increasing demand for precision and efficiency in manufacturing processes. According to a recent report by the International Federation of Robotics, the installation of industrial robots is expected to grow at a compound annual growth rate of 10% over the next few years. This growth is largely attributed to the integration of smart technologies that enhance operational flexibility and precision in CNC machining applications.

One of the most notable advancements in CNC automation is the implementation of collaborative robots, or cobots, designed to work alongside human operators. These systems not only enhance productivity but also improve workplace safety by taking over repetitive or dangerous tasks. Experts suggest that businesses looking to invest in CNC technology should consider systems that integrate AI-driven analytics. This can lead to predictive maintenance, which studies equipment performance data to foresee and prevent potential breakdowns—an approach that can reduce downtime by up to 30%, according to a study by McKinsey.

Tips: When selecting a CNC machine or automation system, prioritize equipment that offers scalability to adapt to future technological advancements. Additionally, ensure that your team receives proper training in robotics and automation to maximize the efficiency of these new technologies in your operations. Embracing automation will not only elevate production efficiency but can also significantly reduce human error in machining processes.

Sustainability Trends in CNC Machining Equipment

As the CNC machining industry evolves, sustainability has emerged as a crucial trend that manufacturers must embrace. According to a report by MarketsandMarkets, the global CNC machining market is expected to reach $100 billion by 2025, with an increasing emphasis on eco-friendly practices. Companies are now investing in energy-efficient machinery and waste reduction technologies, responding to both consumer demand for sustainability and regulatory pressures aiming for lower environmental impact.

In 2025, we can anticipate a significant shift towards the integration of renewable energy sources in CNC machining processes. A study from the International Energy Agency highlights that integrating solar and wind energy into manufacturing operations can reduce carbon emissions by up to 50%. Moreover, advancements in materials like biodegradable composites and recycled metals are becoming more prevalent, aligning with the principles of a circular economy. These innovations not only diminish waste but also enhance the overall efficiency of CNC operations, allowing businesses to produce high-quality parts with a smaller carbon footprint.

Additionally, digital monitoring systems are gaining traction as part of sustainability trends within CNC machining. The use of IoT technology can optimize energy consumption and material usage, providing real-time data that helps manufacturers make informed decisions. According to a recent report from Deloitte, companies that implement smart manufacturing technologies can achieve up to a 30% reduction in resource consumption while improving operational efficiency. As the industry moves forward, the commitment to sustainable practices will define the competitive landscape of CNC machining in 2025 and beyond.

Top CNC Machining Equipment Trends to Watch for in 2025

Integration of AI and Machine Learning in CNC Processes

The integration of Artificial Intelligence (AI) and Machine Learning (ML) in CNC machining processes is poised to revolutionize the manufacturing landscape by 2025. As these technologies mature, they promise enhanced automation, improved precision, and increased efficiency in CNC operations. AI algorithms can analyze vast amounts of data generated during machining processes, leading to predictive maintenance, which minimizes downtime and extends the lifespan of equipment. By predicting tool wear and identifying potential failures before they occur, companies can optimize their production schedules and reduce unexpected maintenance costs.

Moreover, Machine Learning enhances the adaptability of CNC systems, enabling them to learn from historical data and adjust parameters in real time for optimal performance. This capability means that machining operations can be fine-tuned to achieve higher quality outputs with reduced waste. AI-driven insights can also facilitate smarter decision-making, allowing operators to focus on complex tasks while the system handles routine adjustments. As industries increasingly embrace these technologies, the synergy between AI, ML, and CNC machining will not only streamline production processes but also pave the way for innovative approaches to manufacturing challenges.

The Impact of IoT on CNC Machining Operations in 2025

The integration of the Internet of Things (IoT) into CNC machining operations is set to transform the industry landscape by 2025. With the ability to connect various machines and systems, IoT facilitates real-time monitoring and data collection, allowing manufacturers to optimize their workflows. Operators can track machine performance, identify potential issues before they escalate, and streamline maintenance schedules. This proactive approach not only enhances productivity but also reduces downtime, leading to more efficient operations.

Moreover, the adoption of smart sensors and IoT-enabled devices will enhance the precision of CNC machining processes. These technologies can provide continuous feedback on tool conditions, material integrity, and other critical parameters, ensuring that the machining operations maintain high standards of quality. As manufacturers shift towards more automated and connected environments, the ability to analyze vast amounts of data will enable enhanced decision-making, ultimately improving overall product delivery and customer satisfaction. The future of CNC machining looks promising as IoT continues to drive innovation and efficiency in 2025 and beyond.

Top CNC Machining Equipment Trends to Watch for in 2025 - The Impact of IoT on CNC Machining Operations in 2025

| Trend | Description | Impact Level (1-5) | Expected Adoption Rate (%) |

|---|---|---|---|

| Smart Sensors | Integration of sensors to monitor equipment performance. | 5 | 80 |

| Predictive Maintenance | Using IoT data to predict equipment failures before they occur. | 4 | 70 |

| Remote Monitoring | Ability to monitor operations from remote locations. | 4 | 75 |

| Data Analytics | Utilizing big data to analyze trends and improve efficiency. | 5 | 85 |

| Interconnected Systems | Machines communicating with each other for optimized operations. | 4 | 60 |

| Edge Computing | Processing data locally on the machine for real-time responses. | 3 | 50 |

Related Posts

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.