What is CNC Machining Manufacturing and How Does It Benefit Your Business

CNC machining manufacturing has revolutionized the landscape of production across various industries, offering precision, efficiency, and adaptability. According to a report by the Global Industry Analysts, the CNC machining market is projected to reach approximately $100 billion by 2026, driven by the increasing demand for custom parts and the push for automation in manufacturing processes. This highlights not only the growth of the sector but also its pivotal role in enhancing productivity and reducing waste.

Experts in the field, such as Dr. Emily Chen, a leading authority in manufacturing technologies, emphasize the strategic advantages of CNC machining. She stated, "The ability of CNC machining to deliver consistently high-quality parts at a rapid pace is transforming operations for manufacturers, enabling them to stay competitive in a global market." This assertion underscores the necessity for businesses to adopt advanced manufacturing techniques to meet the evolving demands of efficiency and quality.

Incorporating CNC machining manufacturing into business operations not only streamlines processes but also opens avenues for innovation. As companies look to optimize their production workflows, embracing this technology becomes essential for long-term success and sustainability in the contemporary industrial landscape.

What is CNC Machining: A Comprehensive Overview

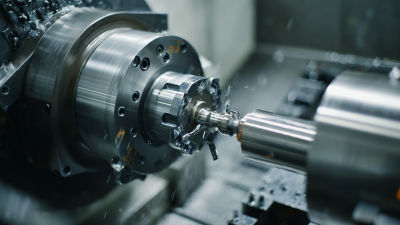

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computer systems to control machine tools. It allows for the precise shaping of materials like metal, plastic, and wood through automated processes, which enhances production efficiency and accuracy. By inputting a detailed computer-aided design (CAD) file, CNC machines can produce intricate parts with minimal human intervention. This technology streamlines manufacturing processes, reducing the likelihood of errors and the need for rework.

One of the significant advantages of CNC machining is its ability to maintain consistency across large production runs. Once a design is programmed into the CNC machine, it can replicate that part countless times with the same level of precision. This capability is particularly beneficial for industries requiring high-volume output, as it ensures that each product meets the exact specifications without variation. Additionally, the flexibility of CNC machining allows for quick adjustments to designs, making it easier for businesses to respond to changing market demands and innovate their product offerings effectively.

CNC Machining Overview and Benefits for Your Business

| Aspect | Description | Benefits |

|---|---|---|

| Definition | CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid block to create precise components. | High precision and repeatability in manufacturing. |

| Material Versatility | Works with various materials including metals, plastics, and composites. | Ability to produce diverse products for different applications. |

| Cost Efficiency | Automated processes reduce labor costs and production time. | Lower overall production costs, increasing profit margins. |

| Production Volume | Suitable for both low and high volume production runs. | Flexibility to meet varying production demands. |

| Quality Control | Integrates advanced monitoring systems for quality assurance. | Reduced defects and improved product reliability. |

| Customization | Easily programmable for custom designs and modifications. | Ability to cater to specific client needs and specifications. |

The Process of CNC Machining: Step-by-Step Explanation

CNC machining is a precise manufacturing process that utilizes computer numerical control systems to automate the machining of parts. Understanding the step-by-step process behind CNC machining can reveal its efficiency and advantages for businesses. The procedure typically begins with design, where engineers create a 3D model using CAD software. This model is then converted into a CNC program that dictates the machinery's movements.

Next, the CNC machine prepares the raw material, often metal or plastic, and secures it in place. The manufacturing process involves several operations, including milling, turning, and drilling. Each step is meticulously executed to ensure that tolerances are maintained within the industry standards, often as tight as ±0.005 inches. Finally, after machining, parts undergo finishing processes such as sanding and polishing, which enhance their functionality and appearance. According to a study by Grand View Research, the CNC machining market is expected to reach USD 100 billion by 2025, highlighting its significance in various industries.

Tips: When considering CNC machining for your business, ensure that the design files are prepared in accordance with the specifications of the chosen material and process. Regularly updating your software and machinery is crucial to maintain competitive edge and efficiency in production. Moreover, investing in skilled operators can dramatically improve the quality and precision of the final products.

CNC Machining Manufacturing Benefits

Advantages of CNC Machining for Businesses: Key Benefits

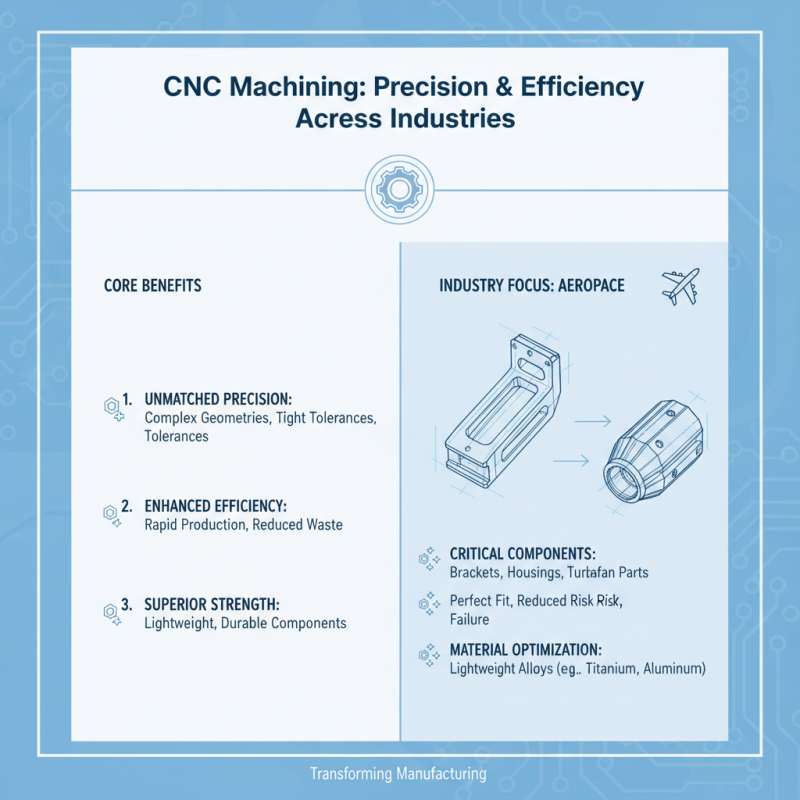

CNC machining has revolutionized the manufacturing landscape, offering unparalleled precision and efficiency for businesses across various industries. One of the primary advantages of CNC machining is its ability to produce complex geometries with consistent accuracy. According to a report by Grand View Research, the CNC machining market is expected to reach $117.93 billion by 2027, indicating a robust demand for this technology. The capability to automate production processes not only reduces human error but also enhances the repeatability of parts, leading to lower defect rates and higher overall quality.

Additionally, CNC machining significantly optimizes material usage, which can lead to substantial cost savings. A study by the Society of Manufacturing Engineers highlights that companies can reduce material waste by as much as 30% through CNC processes. This efficiency is not only economically beneficial but also supports sustainability efforts within businesses, as it minimizes excess materials that might otherwise contribute to landfill waste. Furthermore, the adaptability of CNC machines allows manufacturers to respond quickly to market changes, enabling them to adjust production runs with minimal downtime. This flexibility makes CNC machining a vital asset for businesses aiming to stay competitive in an ever-evolving market.

Applications of CNC Machining in Various Industries

CNC machining has become an essential technique across various industries, providing precision and efficiency that manual methods cannot match. In the aerospace sector, for example, CNC machining is utilized to produce lightweight yet strong components, such as brackets and housings, that are crucial for aircraft performance and safety. The ability to create complex geometries with high tolerance levels ensures that parts fit perfectly, reducing the risk of failure during flight.

In the automotive industry, CNC machining plays a vital role in the production of engine parts, transmission components, and custom fixtures. Its automation capabilities enable manufacturers to scale production while maintaining consistent quality. Furthermore, the versatility of CNC machines allows for the rapid prototyping of new designs, enabling companies to innovate faster and respond to market demands effectively. This adaptability is also evident in the medical field, where CNC machining is used to create surgical tools and implants tailored to specific patient needs, highlighting its importance in improving both product quality and patient outcomes.

Choosing the Right CNC Machining Services for Your Needs

When selecting the right CNC machining services for your business, it's essential to assess various factors that align with your specific needs. First, consider the type of materials you require for your projects. According to a report from the National Association of Manufacturers, approximately 75% of manufacturers face challenges with material selection for CNC machining, which can significantly impact production timelines and costs. Understanding the materials your chosen service can handle will ensure that you receive products that meet your quality standards.

Additionally, evaluate the service provider's capabilities in terms of technology and equipment. A 2021 study by the International Federation of Robotics indicated that companies utilizing advanced CNC technology experience a 20-30% increase in production efficiency. Look for service providers that invest in state-of-the-art machinery and software solutions to guarantee precision and reliability.

Tip: Before proceeding, always request samples or prototypes. This step allows you to assess the quality of work before committing to large orders.

Tip: Don't forget to inquire about lead times and production capacity. Understanding these aspects upfront can help avoid potential delays in your project timelines, ensuring smoother operations for your business. By carefully selecting CNC machining services that cater to your unique requirements, you set the foundation for success in your manufacturing endeavors.

Related Posts

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Unlocking Precision in Manufacturing with the Latest Tool CNC Machine Innovations

-

2025 Top 10 Precision CNC Machining Trends Revolutionizing Manufacturing Efficiency

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.