Why Is CNC Machining Precision Essential for Modern Manufacturing?

CNC machining precision plays a vital role in today's manufacturing landscape. As technology evolves, the demands for accuracy increase. Expert John Smith, a leader in the CNC machining industry, emphasizes this: “Precision isn’t just a requirement; it’s a commitment to quality.” This commitment shapes the design and function of countless products.

Manufacturers rely on CNC machining for intricate designs. A slight error can lead to significant issues down the line. For instance, components that don’t fit correctly can halt production or result in costly recalls. Despite advancements, achieving perfect CNC machining precision remains challenging. Variations in materials and machine calibration can affect results. These unexpected changes prompt manufacturers to constantly adapt their processes.

As the industry grows, the importance of CNC machining precision cannot be overstated. It leads to improved efficiencies and better product performance. However, the journey toward flawless precision is ongoing. Mistakes and learning experiences are part of this journey. Manufacturers must continuously innovate and reflect on their methods to meet rising standards.

Importance of Precision in CNC Machining for Manufacturing Processes

In modern manufacturing, precision in CNC machining holds immense significance. According to a report by the Precision Metalforming Association, 80% of manufacturers consider precision one of their top priorities. It influences product quality, reduces waste, and enhances overall efficiency. With tighter tolerances, components fit together better and function as intended.

Tips: Regularly calibrate your CNC machines. This simple act can drastically improve precision over time.

To illustrate, a small error in machining can lead to significant issues downstream. A study found that a mere 0.01 mm deviation in component dimensions could increase assembly errors by 25%. These mistakes not only increase production costs but also extend lead times, hampering competitiveness in the market.

Tips: Utilize high-quality tools and maintain them diligently. Well-maintained equipment is crucial for sustaining precision.

Ultimately, embracing precision in CNC machining is not just beneficial; it is essential. When precision falters, manufacturers often find themselves in a cycle of revisions and fixes. This cycle can be draining and frustrating, highlighting the need for consistent accuracy in every step of the manufacturing process.

Key Industries Benefiting from CNC Machining Precision

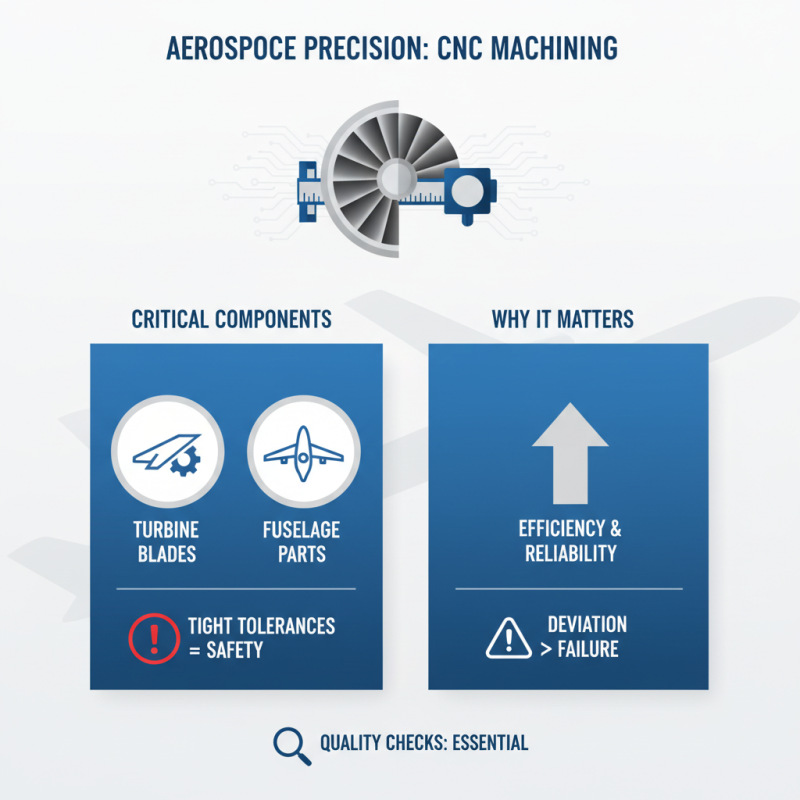

CNC machining precision plays a crucial role in various industries today. The aerospace sector relies heavily on precision to ensure safety and efficiency. Components like turbine blades and fuselage parts must meet strict tolerances. A slight deviation can lead to catastrophic failures. This is why quality checks are vital throughout the manufacturing process.

In the automotive industry, precision machining is equally important. Parts such as engine components and transmission systems require exact measurements. Any inconsistency can affect vehicle performance and driver safety. This industry must constantly assess its processes. Continuous improvement is necessary to maintain high standards.

Medical equipment manufacturing also benefits from CNC precision. Devices like surgical instruments and implants need utmost accuracy. A small error can have serious consequences for patient health. Industries often face challenges in maintaining consistent quality. The pursuit of precision is ongoing, and self-reflection on manufacturing practices is essential.

Technological Advances Enhancing CNC Machining Accuracy

Technological advancements are redefining CNC machining accuracy. High-definition sensors now play a vital role in this evolution. They gather precise data during the machining process. Integrating these sensors can enhance quality control but often requires careful calibration. Even the slightest misalignment can lead to flawed parts.

Moreover, software improvements are reshaping the landscape. Advanced algorithms optimize tool paths, reducing production time. However, these systems need constant updates to maintain efficiency. Some manufacturers still rely on outdated technology. This reliance can hinder their competitiveness, revealing a need for reflection.

Additionally, automation is increasing precision. Robotic arms perform repetitive tasks with exceptional accuracy. Yet, over-reliance on these systems can create vulnerabilities. Unforeseen breakdowns may halt production. Balancing human skills with automation remains a challenge. This interplay demands thoughtful consideration to ensure ongoing improvement in CNC machining accuracy.

Challenges in Maintaining Precision in CNC Machining

CNC machining is known for its precision. However, maintaining that precision can be challenging. Variabilities in material properties often affect the outcome. Different metals expand or contract at varying rates. This affects dimensions, leading to possible errors. Even minor temperature changes can alter results.

Tool wear is another critical factor. When CNC tools wear down, they lose their cutting edge. This can lead to inconsistencies in the finished product. Regular maintenance is essential, yet often overlooked. Operators must be diligent in monitoring the condition of tools.

Programming errors can also cause significant issues. A simple mistake in the code can result in an incorrect cut. These errors, while small, can have major implications. They often go unnoticed until the final inspection. Precision in CNC work is paramount, yet these obstacles require constant attention and improvement.

Why Is CNC Machining Precision Essential for Modern Manufacturing? - Challenges in Maintaining Precision in CNC Machining

| Dimension | Description | Challenges | Solutions |

|---|---|---|---|

| Tolerances | The acceptable range of variation in a physical dimension. | Maintaining tight tolerances can be challenging due to machine wear. | Regular calibration and maintenance of CNC machines. |

| Material Properties | The characteristics of the raw material being machined. | Variations in material properties can affect precision. | Careful selection of materials and thorough testing before machining. |

| Tool Wear | The degradation of cutting tools over time. | Worn tools can lead to decreased accuracy and poor surface finish. | Implementing regular tool inspection and timely replacement. |

| Machine Calibration | The process of adjusting and aligning machinery for accuracy. | Infrequent calibration can lead to inaccurate results. | Scheduled calibration routines and documenting adjustments. |

| Environmental Factors | External conditions like temperature and humidity affecting manufacturing. | Temperature variations can cause expansion or contraction of materials. | Controlled environmental conditions in manufacturing areas. |

Future Trends in CNC Machining Precision and Applications

CNC machining precision is evolving rapidly. Future trends indicate a significant shift toward automation and artificial intelligence. These technologies will enhance accuracy and reduce errors. With machine learning algorithms, CNC systems can learn from past operations. This allows for more precise adjustments during the machining process.

The integration of advanced sensors is another exciting development. Smart sensors collect real-time data, detecting deviations immediately. This feedback loop ensures consistent quality, minimizing waste. However, there are challenges. Maintaining these systems requires skilled personnel. The industry faces a skills gap, potentially hindering progress.

Moreover, industries are exploring new materials that demand higher precision. Composite materials, for instance, can be difficult to work with. Manufacturers must adapt their processes accordingly. This will require iterating on existing techniques and reflecting on their limitations. Continuous improvement is essential to meet these new demands in CNC machining.

Impact of CNC Machining Precision on Manufacturing Output

This bar chart illustrates the increase in manufacturing output over the years 2019 to 2023, showcasing how the precision of CNC machining has contributed to enhanced productivity in modern manufacturing processes. As precision improves, so does the overall output, reflecting the importance of CNC technology in the industry.

Related Posts

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

What is CNC Machining Equipment and How Does It Work Explained

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Top 10 CNC Machine Tools Every Engineer Should Know in 2023

-

How to Optimize CNC Machining Manufacturing for Maximum Efficiency and Quality

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.