Unlocking the Secrets of CNC Machining Precision for Optimal Performance

In today's competitive manufacturing landscape, achieving exceptional CNC machining precision is paramount for businesses aiming to enhance productivity and optimize performance. According to a recent report by SME, precision machining technologies are projected to grow at a CAGR of 6.3% between 2021 and 2026, underscoring the increasing demand for accuracy in machined components.

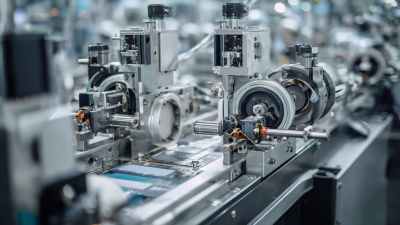

CNC machining, renowned for its ability to produce intricate parts with minimal tolerances, has become indispensable in sectors such as aerospace, automotive, and medical devices. By leveraging advanced techniques and embracing automation, manufacturers can unlock the secrets to optimal CNC machining precision, thus driving innovation and maintaining a competitive edge. Understanding the key factors that influence precision not only improves product quality but also significantly reduces operational costs, making it crucial for businesses to invest in refining their CNC practices.

CNC machining, renowned for its ability to produce intricate parts with minimal tolerances, has become indispensable in sectors such as aerospace, automotive, and medical devices. By leveraging advanced techniques and embracing automation, manufacturers can unlock the secrets to optimal CNC machining precision, thus driving innovation and maintaining a competitive edge. Understanding the key factors that influence precision not only improves product quality but also significantly reduces operational costs, making it crucial for businesses to invest in refining their CNC practices.

Understanding CNC Machining: Key Factors Influencing Precision

CNC machining is at the forefront of modern manufacturing, with precision being a critical factor in ensuring optimal performance and product quality. One of the key determinants of CNC machining precision is the machine's rigidity. According to a study by the American Society of Mechanical Engineers, increased machine rigidity can enhance accuracy by up to 30%, minimizing vibrations that can lead to dimensional inaccuracies. Additionally, the precision of the computer numerical control (CNC) software plays a significant role, as it dictates the machine's ability to follow specified paths and shapes with high fidelity.

Another critical aspect influencing precision is the tooling used in the CNC process. Reports from the Society of Manufacturing Engineers indicate that using high-quality cutting tools can improve the consistency of tolerances achieved during machining, often within ±0.005 inches. Furthermore, tool wear and proper maintenance are vital; studies show that neglected tools can lead to degradation in precision, affecting the entire production cycle. Understanding and optimizing these factors is essential for manufacturers aiming to improve their CNC machining processes and achieve superior dimensional accuracy in their products.

Essential Tools and Software for Enhancing CNC Machining Accuracy

CNC machining precision is vital for achieving optimal performance in various manufacturing processes. Essential tools and software play a crucial role in enhancing this accuracy. High-quality cutting tools, such as end mills and drills, are engineered to minimize tolerances and maintain consistency in machining operations. These tools, when paired with advanced coatings, can significantly extend tool life and improve surface finish, which are vital for precision in CNC operations.

In addition to physical tools, software solutions are indispensable for enhancing CNC machining accuracy. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software streamline the design and production processes, allowing for precise programming of CNC machines. These platforms enable detailed simulations and toolpath optimizations, minimizing errors before actual machining takes place. Furthermore, utilizing advanced feedback systems and monitoring tools can enhance real-time adjustments, ensuring that the machining process remains within the desired specifications.

In essence, the combination of superior tools and sophisticated software creates a synergistic effect that unlocks the full potential of CNC machining precision.

Tips for Selecting the Right Materials for Optimal CNC Performance

When it comes to CNC machining, selecting the right materials is crucial for achieving optimal performance and maintaining precision. According to a report by LNS Group, approximately 70% of machining problems can be traced back to material selection issues. Factors such as mechanical properties, thermal stability, and machinability play significant roles in the overall efficiency of the machining process. For instance, materials like aluminum 6061 are favored for their excellent machinability and strength-to-weight ratio, making them ideal for industries such as aerospace and automotive.

Additionally, understanding the specific requirements of the project can further guide material choice. A study by the American Society of Mechanical Engineers (ASME) emphasizes that harder materials may require specialized tooling and longer machining times, which can impact production schedules and costs. For projects demanding high precision, such as medical device manufacturing, materials like titanium alloys or high-performance polymers offer superior durability and can withstand extreme conditions. Balancing between material properties and the machining capabilities ensures that manufacturers can unlock the full potential of their CNC machinery, leading to enhanced productivity and finished product quality.

Common Mistakes to Avoid in CNC Machining Processes

CNC machining is a critical component of modern manufacturing, allowing for high precision and efficiency. However, there are common pitfalls that can undermine the performance of CNC processes. One major mistake is improper tool assembly, which can lead to inaccuracies in machining. Ensuring that tools are correctly aligned and maintained is essential to avoid these errors. Additionally, neglecting the calibration of CNC machines can introduce dynamic machining errors, negatively affecting the quality of the final product.

Another frequent issue arises from inadequate training and understanding of CNC systems among operators. Insufficient knowledge about the capabilities and limitations of the machine can result in improper settings, leading to waste of material and time. Furthermore, overlooking the importance of regular maintenance can exacerbate wear and tear, reducing machine precision over time. By addressing these common mistakes, manufacturers can enhance the performance of their CNC machining processes and achieve optimal results.

Maintenance Best Practices to Ensure Long-Term CNC Precision

Maintaining CNC machining precision is crucial for optimal performance in manufacturing processes. Regular maintenance not only extends the lifespan of machinery but also ensures that tolerances are consistently met. According to a report by the Association for Manufacturing Technology, up to 70% of machinery failures can be attributed to inadequate maintenance practices. Implementing a structured maintenance program can reduce breakdowns significantly, promoting uninterrupted production and improved accuracy.

One of the best practices in CNC maintenance is to establish a daily inspection routine. Checking for loose screws, ensuring proper lubrication, and verifying calibration can help catch potential issues before they escalate. The National Institute of Standards and Technology (NIST) emphasizes that maintaining temperature and environmental stability around CNC machines can reduce thermal expansion, which often affects precision. Furthermore, periodic software updates and tool inspections can lead to consistently high-quality output, which is essential for industries where precision machining is paramount, such as aerospace and automotive sectors. In fact, research indicates that tools and equipment maintained correctly can improve machining accuracy by up to 30%, underscoring the importance of diligent maintenance practices.

Unlocking the Secrets of CNC Machining Precision for Optimal Performance - Maintenance Best Practices to Ensure Long-Term CNC Precision

| Maintenance Practice | Frequency | Impact on Precision | Notes |

|---|---|---|---|

| Lubrication of Moving Parts | Weekly | Prevents wear, ensuring smooth operation | Use recommended oils for specific components |

| Calibration of CNC Machines | Monthly | Critical for precision accuracy | Follow the manufacturer's calibration guide |

| Inspection of Tooling | Bi-Weekly | Directly affects cutting quality | Replace worn tools immediately |

| Cleaning of Machine Parts | Weekly | Prevents contamination and damage | Use non-abrasive materials for cleaning |

| Cooling System Maintenance | Quarterly | Avoids overheating, ensuring integrity | Check coolant levels and quality |

Related Posts

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.