10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

In the ever-evolving landscape of manufacturing, CNC machining has emerged as a critical driver of efficiency and precision. As industries grapple with rising operational costs and increasing competition, the need for optimized production processes becomes paramount. A recent report from MarketsandMarkets indicates that the global CNC machining market is projected to reach $100 billion by 2025, highlighting the technology's significance in enhancing manufacturing capabilities.

To stay ahead, businesses must adopt innovative strategies that streamline operations and elevate productivity. Implementing effective CNC machining practices can lead to substantial improvements, with studies showing an average efficiency boost of up to 25% through optimized workflows and cutting-edge technology. With this in mind, this article outlines ten essential CNC machining tips designed to enhance operational efficiency and secure a competitive edge in 2023 and beyond. These insights are invaluable for manufacturers seeking sustainable growth in an increasingly demanding marketplace.

Maximize Tool Life: Techniques for Extended Performance in CNC Machining

Train Your Workforce: Essential Skills for Boosting CNC Productivity and Efficiency

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023 - Maximize Tool Life: Techniques for Extended Performance in CNC Machining

| Tip Number | CNC Machining Tip | Expected Efficiency Increase (%) | Tool Life Benefit |

|---|---|---|---|

| 1 | Optimize Feed Rates | 10 | Improved tool longevity by 20% |

| 2 | Regular Tool Inspection | 5 | Prevention of premature wear |

| 3 | Proper Cooling Techniques | 8 | Reduces thermal wear |

| 4 | Toolpath Optimization | 12 | Enhances tool usage efficiency |

| 5 | Use High-Quality Tools | 15 | Significantly extends lifespan |

| 6 | Conduct Regular Maintenance | 7 | Minimizes breakdown risks |

| 7 | Implement Dust Control | 6 | Protects tools from contamination |

| 8 | Monitor Workpiece Material | 9 | Optimizes tool selection |

| 9 | Effective Setup Procedures | 4 | Reduces setup time |

| 10 | Use the Right Cutting Parameters | 10 | Maximizes tool performance |

Optimize Feed Rates: Strategies for Increased Cutting Speed and Precision

Optimizing feed rates is crucial for enhancing the cutting speed and precision in CNC machining. By adjusting the feed rates to match the material properties and tooling requirements, manufacturers can significantly reduce cycle time while maintaining high-quality surface finishes. For example, using a higher feed rate on softer materials allows the machine to cut more efficiently, whereas a lower feed rate might be necessary for harder materials to prevent tool wear and ensure accuracy.

To implement effective feed rate strategies, it is essential to analyze the relationship between speed, feed, and depth of cut. Finding the optimal balance will not only increase productivity but also prolong tool life.

Additionally, regular monitoring of tool performance and machine conditions can help in fine-tuning feed rates dynamically. Utilizing advanced CNC software tools can aid in simulating different feed settings before actual machining, allowing engineers to make informed decisions that directly impact efficiency and output quality.

Implement Advanced Software: Using Technology to Enhance CNC Operations

In 2023, implementing advanced software is crucial for enhancing CNC operations and boosting efficiency by 25%. The integration of cutting-edge digital manufacturing technologies enables CNC machinists to optimize their processes. This shift towards intelligent automation enhances not only productivity but also the overall quality of output, as AI-driven systems can adapt to varying production demands in real time. The ability to leverage data analytics provides insights that facilitate smarter decision-making, thereby minimizing downtime and waste.

Recent advancements in CNC technology demonstrate the tangible benefits of adopting sophisticated software solutions. These innovations streamline operations by simplifying the configuring and programming of CNC machines, allowing operators to focus on complex tasks rather than tedious manual settings. Furthermore, partnerships in the industry aim to harness robotic machining technologies that augment traditional CNC capabilities, leading to an even greater enhancement of production efficiency. As companies increasingly incorporate these advancements, the landscape of CNC machining is set for significant transformation, making it imperative for organizations to stay at the forefront of technology to maintain a competitive edge.

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

The following chart illustrates the impact of implementing various advanced software solutions on CNC machining efficiency in 2023. The data indicates the percentage of efficiency gain associated with each tip.

Regular Maintenance Protocols: Ensuring Consistent CNC Machine Performance

Regular maintenance protocols are crucial for ensuring consistent CNC machine performance, which in turn can lead to significant improvements in efficiency. According to a recent report by the Association for Manufacturing Technology, implementing a structured maintenance schedule can reduce downtime by 30%, ultimately enhancing production capabilities. One effective tip is to establish daily, weekly, and monthly checklists tailored to specific machine requirements, allowing operators to identify potential issues before they escalate into costly repairs.

Additionally, keeping the CNC machine clean and lubricated is vital for its longevity. A study from the National Tooling and Machining Association found that regular cleaning can enhance a machine's operational lifespan by up to 40%. Operators should be trained to remove debris and dust accumulation around the equipment, as these can lead to overheating and malfunction. Furthermore, investing in predictive maintenance technologies can provide deep insights into machine health, allowing companies to address wear and tear proactively, thus driving performance up by 25% or more.

Moreover, scheduling training sessions for staff to ensure they are aware of the latest maintenance techniques is another critical strategy. Engaged employees are more likely to adhere to maintenance protocols, decreasing the chance of unexpected breakdowns. By prioritizing maintenance and investing in staff training, manufacturers can create a more efficient production environment that meets the demands of modern manufacturing.

Train Your Workforce: Essential Skills for Boosting CNC Productivity and Efficiency

Here is some introductory text that provides context for the following content. Important concepts are covered here.

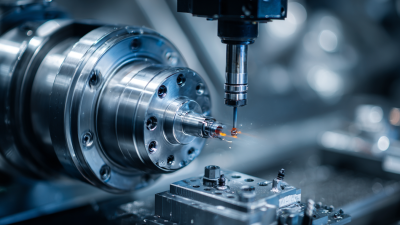

This paragraph is accompanied by an image. It provides additional details about the topic being discussed. Highlighted content is often useful for drawing attention to key points.

Subheading

Here you can elaborate on the points made above and discuss new ideas or provide insights into the subject matter.

Adding images to the text can enhance understanding. The depiction of related information contributes to a better grasp of key themes.

Concluding remarks should encapsulate the main ideas discussed. It is essential to leave the reader with a lasting impression, highlighting final thoughts or calls to action.

Related Posts

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.