10 Essential Tips for Choosing the Right Machine Tool for Your Workshop

Choosing the right machine tool for your workshop can significantly enhance productivity and efficiency in your projects. With the vast range of options available today, it can be overwhelming to determine which machine tool will best meet your needs.

From precision lathes to versatile milling machines, understanding the specific functions and capabilities of each type of machine tool is crucial for making an informed decision. The right choice not only depends on the type of work you intend to do but also on factors such as space, budget, and skill level.

From precision lathes to versatile milling machines, understanding the specific functions and capabilities of each type of machine tool is crucial for making an informed decision. The right choice not only depends on the type of work you intend to do but also on factors such as space, budget, and skill level.

This guide provides ten essential tips that will simplify the selection process and ensure that you invest in a machine tool that is perfectly suited for your workshop. Each tip is designed to help you evaluate your requirements thoroughly and consider various aspects such as the machine's specifications, reliability, and after-sales support. By following these guidelines, you will be better equipped to make a choice that enhances your craft while safeguarding your investment. Whether you are a hobbyist or a seasoned professional, selecting the right machine tool could be a game changer in your workshop dynamics.

Identifying Your Workshop Needs: Assessing Projects and Requirements

When selecting the right machine tool for your workshop, it’s crucial to first identify your specific needs by assessing the types of projects you plan to undertake. According to a report by the Manufacturing Institute, 88% of manufacturers express a need for advanced machine tools that can increase efficiency and product precision. Understanding your project requirements, such as materials and production volume, will help you determine the essential features and capabilities your machine tool should possess.

For instance, if your projects primarily involve detailed woodworking, you may require a CNC router with advanced automation options. On the other hand, if metalworking is more in line with your objectives, investing in a high-quality lathe or milling machine might be more beneficial. Additionally, a survey conducted by the American Society of Mechanical Engineers found that 74% of workshop owners reported that initial assessments of their production needs directly influenced their machine tool decisions. This underscores the importance of a thorough evaluation to ensure that your investments meet not just immediate projects but also long-term workshop goals.

Understanding Different Types of Machine Tools: A Comprehensive Overview

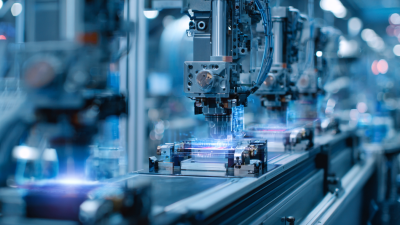

When choosing the right machine tool for your workshop, it's essential to understand the different types available in the market. There are several categories of machine tools, including CNC machines, lathes, milling machines, and grinders, each serving specific functions in the manufacturing process. CNC (Computer Numerical Control) machines are becoming increasingly popular due to their precision and efficiency, allowing for intricate designs and repeatable results. On the other hand, traditional lathes and milling machines are invaluable for more hands-on work and can be more suitable for smaller workshops with varying needs.

The growth of the machine tool market indicates a rising demand for advanced technologies that enhance productivity and reduce operational costs. Insights from recent market research show a trend towards automation and data-driven decision-making, pushing manufacturers to adopt tools that not only meet today's requirements but also adapt to future challenges. Understanding the advantages and limitations of each machine type will empower workshop owners to make informed decisions that align with their specific production goals.

Evaluating Budget Constraints: Balancing Cost and Quality

When selecting the right machine tool for your workshop, budget constraints play a crucial role in balancing cost and quality. According to recent industry reports, nearly 60% of small to medium-sized enterprises cite budgetary limits as the primary obstacle to acquiring advanced machinery. This underscores the need for careful evaluation of your financial situation before making a purchase.

Tip 1: Assess your workshop's specific needs and align them with your budget. Determine the essential features that will enhance productivity without overspending. Tip 2: Research various suppliers' offerings to find quality tools that fit within your financial limits. Don’t overlook second-hand or refurbished machines, which can provide significant savings without compromising on performance. Tip 3: Consider the long-term costs, including maintenance and consumables, as they can impact your total expenditure. Investment in higher-quality tools often results in lower overall operational costs, making them a more viable option in the long run.

Balancing cost with quality is paramount. A recent study found that investing an additional 20% upfront on high-quality tools can lead to a 30% decrease in repair and replacement costs over five years. Keep these insights in mind as you navigate your purchasing decisions.

Considering Space and Layout: Optimizing Workshop Design for Tools

When designing a workshop, one of the most critical aspects to consider is the available space and how best to utilize it for machine tools. Each tool has distinct operational requirements, including the necessary room for safe maneuvering and maintenance. Before selecting any equipment, it is vital to measure your workspace accurately and plan the layout to optimize workflows. A well-thought-out arrangement can help prevent clutter, allow for efficient processes, and improve operator safety.

Additionally, consider the type of projects you will undertake and the tools that best fit those tasks. Arrange machines in a logical sequence based on your workflow, which will help in minimizing unnecessary movement and enhancing productivity. Incorporating modular design principles can also be beneficial, allowing for flexibility to adapt the workshop layout as your needs evolve or as you acquire new tools. Prioritizing functionality while maximizing your space will ultimately lead to a more efficient and effective workshop environment.

Tool Selection Factors

Safety Features and Maintenance: Ensuring Long-Term Use and Protection

When selecting the right machine tools for your workshop, prioritizing safety features is essential for long-term use and protection of both the equipment and personnel. According to a report by the American National Standards Institute (ANSI), over 50% of workplace accidents involving machinery are related to inadequate safety measures. Incorporating tools with built-in safety mechanisms, such as automatic shut-off systems and emergency stop buttons, can significantly reduce the risk of injuries, ensuring a safer operating environment.

Moreover, regular maintenance plays a crucial role in the longevity and efficiency of machine tools. The National Institute for Occupational Safety and Health (NIOSH) recommends a structured maintenance schedule that includes daily inspections and routine checks to identify and rectify potential hazards. Data indicates that well-maintained machinery can enhance operational efficiency by up to 30%, while also extending the lifespan of the tools. By prioritizing safety features and adhering to consistent maintenance practices, workshop owners can protect both their investments and their workforce.

Related Posts

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

The Future of Machine Manufacturing Innovations Transforming Industries

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.