10 Essential Tips for Choosing the Right Machine Tool in CNC

In the rapidly evolving world of manufacturing, the selection of the right machine tool in CNC (Computer Numerical Control) operations stands as a pivotal factor for achieving precision and efficiency. According to a report by the International Federation of Robotics, the global market for CNC machine tools is expected to exceed $90 billion by 2025, highlighting the growing demand for advanced machining solutions. As manufacturers strive to enhance productivity and reduce operational costs, understanding the nuances of choosing the appropriate machine tool becomes essential.

Renowned industry expert Dr. Thomas Schmid, a leading authority in CNC technologies, emphasizes, "Selecting the right machine tool in CNC is not just about the specifications; it's about aligning the tool's capabilities with the specific demands of your production tasks." This statement underscores the critical need for a strategic approach when evaluating various machine tools, considering factors such as material compatibility, complexity of the parts being produced, and the required level of automation. By adopting a well-informed selection process, businesses can ensure they invest in the most suitable machine tool, thereby optimizing their manufacturing processes and staying competitive in a challenging market.

Understanding Different CNC Machine Tool Types for Your Needs

When selecting the right CNC machine tool, it is crucial to understand the various types of machines available and how they align with your specific manufacturing needs. The global CNC machine tool market is projected to grow significantly, expanding from $86.24 billion in 2025 to $141.65 billion by 2032, with a compound annual growth rate (CAGR) of 7.3%. This growth is driven by increasing demands for precision machining and advancements in automated manufacturing processes.

Different CNC machine types, such as lathes, milling machines, and grinding machines, offer distinct capabilities that cater to various applications. As industries continue to embrace automation and digital tools, selecting the right machine becomes even more imperative. For example, the precision parts market is set to exceed $2.3 billion by 2023, highlighting the rising need for high-precision components in sectors such as automotive, aerospace, and medical industries.

Understanding these market dynamics will help businesses make informed decisions when investing in CNC technology to enhance productivity and maintain competitive advantage.

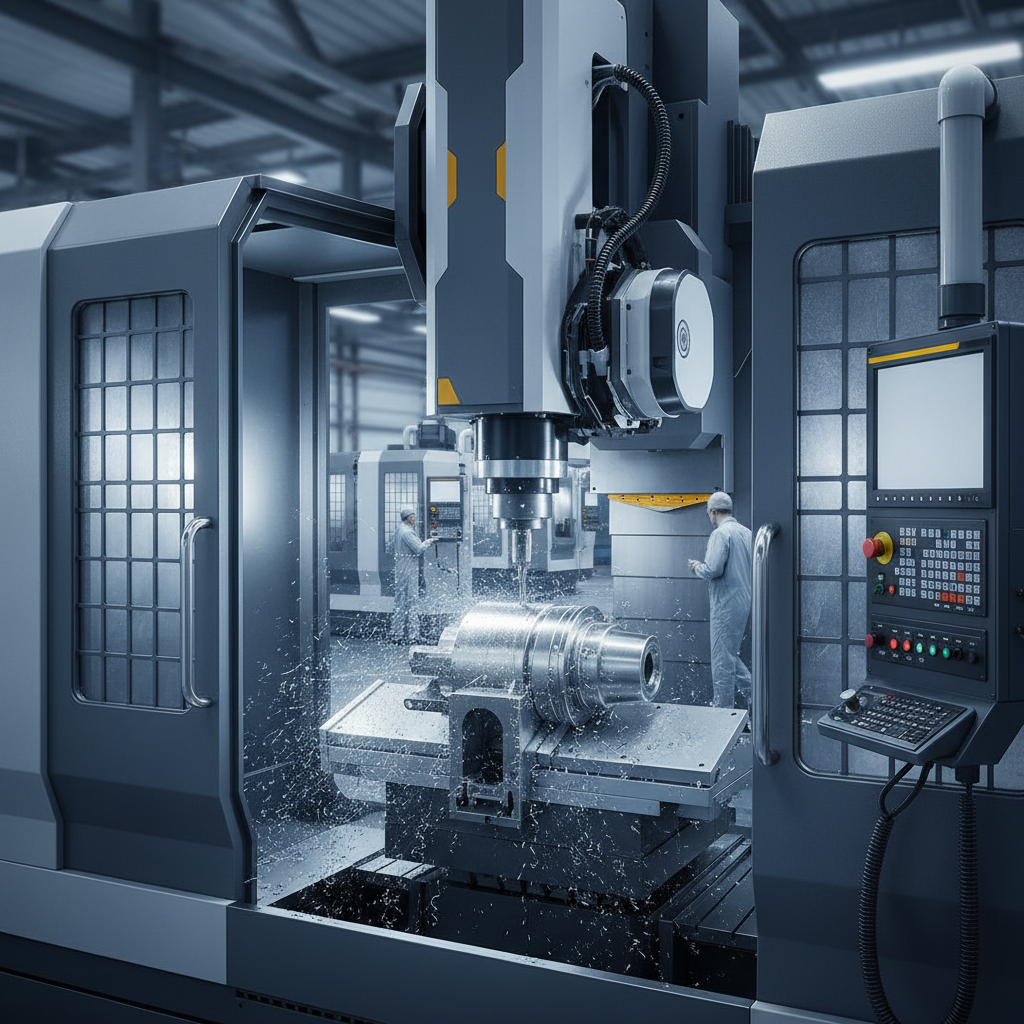

Evaluating Precision and Accuracy in CNC Machining Equipment

When selecting CNC machining equipment, evaluating precision and accuracy is paramount. The importance of precision engineering cannot be overstated, particularly in industries where minute tolerances are critical. The recent market projections indicate that the precision engineering machines sector is poised for significant growth, suggesting an increasing demand for high-quality, accurate equipment. This trend is underscored by advancements in technologies like AI-driven automation for drilling, which enhances path optimization and minimizes errors, ultimately improving the precision of the final output.

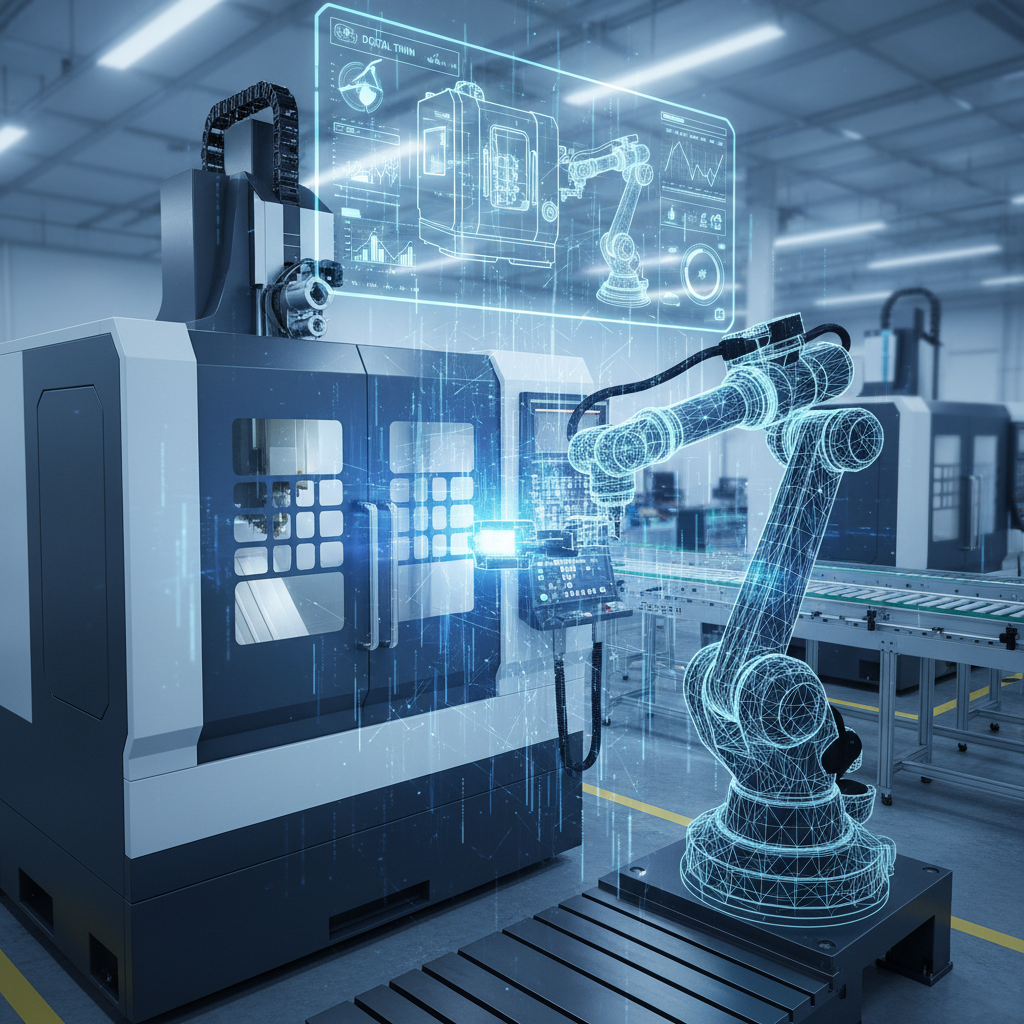

Moreover, the emergence of concepts such as digital twins marks a revolutionary step in the realm of CNC machining. By creating a virtual counterpart for physical machines, manufacturers can ensure a seamless connection that aligns with operational realities. This proactive approach not only elevates precision in part manufacturing but also mitigates risks associated with machinery collisions, further highlighting the necessity of investing in reliable and accurate tooling solutions. As the market evolves, integrating such innovations will be crucial for businesses striving to maintain a competitive edge in precision machining.

Analyzing the Cost-Effectiveness of Various CNC Tool Options

When selecting the right CNC machine tool, understanding the cost-effectiveness of various options is paramount. According to a market research study by Custom Market Insights, the CNC metal machining market is experiencing significant growth, fueled by the increasing demand for precision components in various industries. This trend is particularly evident with superalloys such as Hastelloy X, which are critical in sectors like aerospace, where performance and reliability are non-negotiable. The tech-economic analysis reveals that while initial investments in advanced CNC tools may be higher, the long-term benefits often outweigh the costs through enhanced productivity and reduced waste.

Furthermore, the integration of cutting-edge technologies, such as Artificial Intelligence (AI) in CNC machining, is revolutionizing operations by optimizing processes and minimizing downtime. AI-driven approaches not only improve precision and efficiency but also play a crucial role in the cost-effectiveness of CNC operations. Companies can leverage these technologies to analyze machine performance and streamline their operations, leading to significant savings in both time and materials. As the market for CNC machining continues to evolve, understanding the cost implications of these advanced tools will be essential for businesses aiming to remain competitive in an ever-changing landscape.

Considering Software Compatibility and Integration for CNC Machines

When considering the integration of software in CNC machine tools, understanding compatibility is crucial. The advancements in digital twin technology offer a powerful pathway for manufacturers to enhance their machining capabilities. By utilizing real-time software solutions, CNC machines can not only optimize their performance but also improve their interaction with modern robotics. This synergy between hardware and intelligent software creates a more cohesive manufacturing process, where complexities are managed with greater efficiency.

Moreover, as the CNC machine market continues to grow, propelled by a rising demand for precision and automation, it becomes essential for manufacturers to adopt a system-based approach. Integrating next-generation tooling with CNC machines streamlines operations and maximizes productivity. Companies that prioritize software compatibility will be better positioned to adapt to evolving technologies, ensuring that their machining strategies are robust and future-proof. Embracing these changes can lead to improved shopfloor performance and the ability to meet increasingly sophisticated market demands.

Assessing Maintenance and Support for Long-Term CNC Tool Reliability

When selecting the right machine tool for CNC applications, assessing maintenance and support is crucial for ensuring long-term reliability. A machine tool's performance is often contingent on the availability of timely and effective maintenance services. Before making a purchase, it is essential to investigate the manufacturer's support reputation, the accessibility of spare parts, and the availability of skilled technicians. Regular maintenance can significantly reduce downtime and enhance the performance of the machinery, ensuring that production processes remain smooth and efficient.

Moreover, consider the training and resources provided by the manufacturer. Comprehensive training programs for operators can lead to better utilization of the machine tool, minimizing errors that could lead to costly repairs. Additionally, manufacturers that offer extensive documentation and support materials create a more user-friendly experience. Investing in a machine tool with robust maintenance support not only contributes to longevity but also guarantees that your investment will yield the best returns over its operational life.

10 Essential Tips for Choosing the Right Machine Tool in CNC

Related Posts

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

How to Choose the Best Precision Machining and Manufacturing Services for Your Business Needs

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.