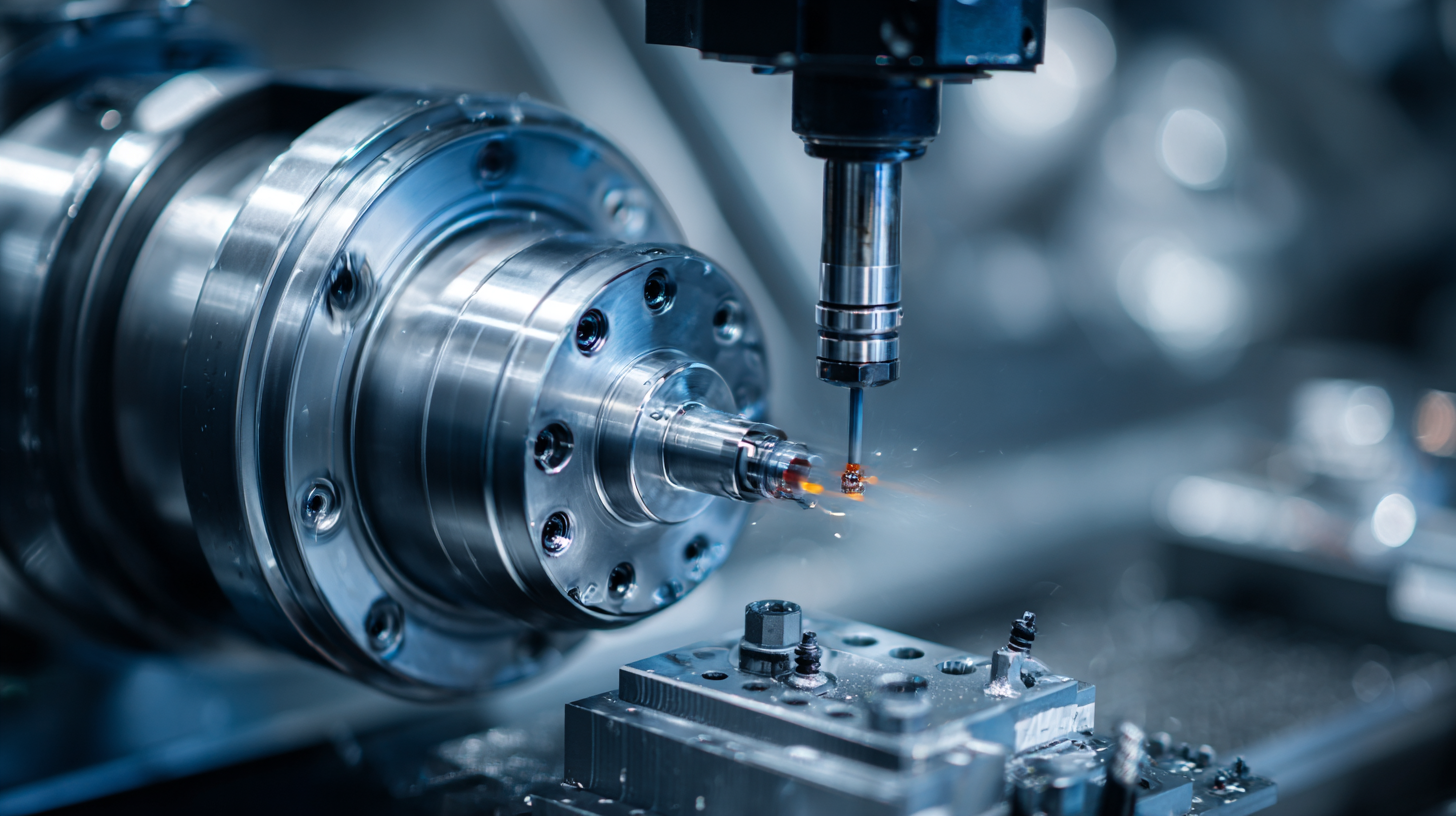

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

In the rapidly evolving landscape of modern manufacturing, precision CNC machining stands out as a pivotal technology driving innovation across various industries. This advanced machining process, characterized by its ability to produce intricate and highly accurate components with minimal human intervention, is revolutionizing how products are designed, developed, and manufactured. As industries strive to enhance efficiency, reduce waste, and improve product quality, the adoption of precision CNC machining becomes increasingly essential. This article explores the transformative impact of precision CNC machining on innovative industries, highlighting its role in meeting the demands of complex designs and customization while ensuring sustainability. By unlocking new possibilities and optimizing production processes, precision CNC machining not only reshapes the manufacturing landscape but also positions companies at the forefront of technological advancement. As we delve into the future of manufacturing, understanding the significance of precision CNC machining is crucial for embracing the challenges and opportunities that lie ahead.

In the rapidly evolving landscape of modern manufacturing, precision CNC machining stands out as a pivotal technology driving innovation across various industries. This advanced machining process, characterized by its ability to produce intricate and highly accurate components with minimal human intervention, is revolutionizing how products are designed, developed, and manufactured. As industries strive to enhance efficiency, reduce waste, and improve product quality, the adoption of precision CNC machining becomes increasingly essential. This article explores the transformative impact of precision CNC machining on innovative industries, highlighting its role in meeting the demands of complex designs and customization while ensuring sustainability. By unlocking new possibilities and optimizing production processes, precision CNC machining not only reshapes the manufacturing landscape but also positions companies at the forefront of technological advancement. As we delve into the future of manufacturing, understanding the significance of precision CNC machining is crucial for embracing the challenges and opportunities that lie ahead.

The Evolution of CNC Machining and Its Impact on Modern Manufacturing

The evolution of CNC machining has redefined modern manufacturing processes, showcasing significant advancements that align with the demands of innovative industries. Recent reports indicate that the global market for CNC vertical machining centers is projected to grow by USD 1.09 billion from 2025 to 2029, driven largely by the burgeoning demand for CNC tools and the integration of AI technology. This growth signifies not only an increase in production capabilities but also a shift towards smarter manufacturing solutions. The infusion of AI facilitates automation, refining machining precision, and improving operational efficiency, which is vital for modern industrial applications.

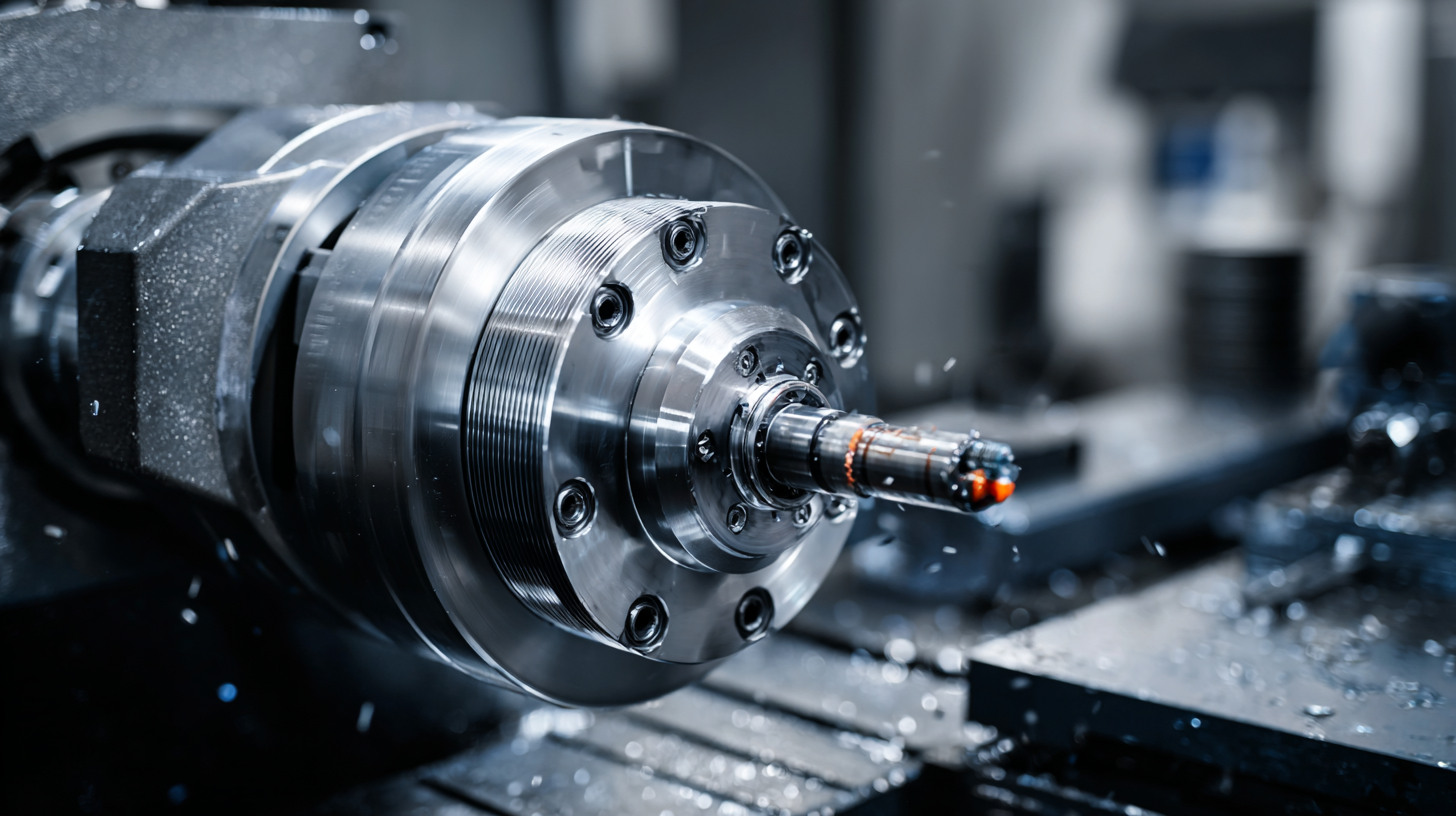

Additionally, the 5-axis CNC machining centers market is set to expand by USD 792.5 million between 2024 and 2028, propelled by advancements in self-optimized machine cutting techniques. This evolution highlights how adaptive technologies enhance precision and ensure accuracy in complex manufacturing tasks. As industries increasingly adopt these cutting-edge CNC machining solutions, the transformative power of technology like AI and robotic automation become central to their operational strategies, ultimately leading to enhanced productivity and sustainability in manufacturing practices.

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

Key Technologies Driving Precision CNC Machining Forward

The landscape of manufacturing is being transformed by precision CNC machining, driven by cutting-edge digital technologies. These advancements enable manufacturers to streamline processes and enhance product quality with unprecedented accuracy. Technologies such as automation, advanced software algorithms, and real-time data analytics are pivotal in improving operational efficiency. As industries strive for innovation, precision CNC machining stands at the forefront, facilitating rapid prototyping and reducing time-to-market.

Tip: Embrace automation in your manufacturing processes. It not only reduces human error but also allows for around-the-clock production, maximizing output without compromising quality.

Moreover, the integration of IoT into CNC machining systems provides valuable insights, enabling predictive maintenance and minimizing downtime. This ensures that machines operate at optimal performance levels, thereby enhancing productivity across the board. As manufacturers increasingly adopt these innovative technologies, the competitive edge gained through precision CNC machining becomes vital for sustaining growth in today's fast-paced market.

Tip: Invest in training your workforce to understand new technologies. Upskilling employees ensures they can effectively leverage new tools and techniques, ultimately leading to better overall performance.

How Precision CNC Machining Enhances Product Innovation and Design Flexibility

Precision CNC machining has revolutionized the landscape of product innovation by offering unparalleled design flexibility and accuracy. In industries where micro-level precision is vital, such as aerospace, medical devices, and automotive, CNC machining allows for the creation of highly complex geometries that were previously unattainable. This technology enables engineers to iterate designs rapidly, ensuring that prototypes are not only functional but also optimized for performance. As a result, manufacturers can bring innovative products to market faster, capitalizing on new trends and consumer demands.

Moreover, the adaptability of CNC machining processes facilitates customization, allowing businesses to tailor products to meet specific client needs. Companies can swiftly adjust their machining programs to produce variations in design without the need for extensive retooling or downtime. This level of agility is crucial in today’s fast-paced market, where staying ahead of competitors often hinges on the ability to offer bespoke solutions. By leveraging precision CNC machining, industries can not only enhance their design capabilities but also foster a culture of continuous innovation, ensuring their products remain at the forefront of technology and engineering excellence.

The Role of CNC Machining in Sustainable and Efficient Manufacturing Practices

CNC machining is transforming the manufacturing landscape by promoting sustainable and efficient practices. According to a report by the International Data Corporation (IDC), precision machining can enhance production efficiency by more than 30%, significantly reducing waste generated during production. This aligns seamlessly with the increasing demand for eco-friendly manufacturing processes in various industries, from automotive to aerospace. Furthermore, CNC machining minimizes human error, ensuring that each piece produced meets the highest quality standards, which, in turn, leads to lower rejection rates and reduced resource usage.

**Tips:** To further enhance sustainability in CNC machining, consider implementing a closed-loop system for recycling machining fluids. Regularly maintaining CNC machines can also extend their lifespan, ensuring that they operate at optimal efficiency while consuming less energy.

In addition to environmental benefits, CNC machining plays a crucial role in innovative industries by enabling small batch production without sacrificing quality. A study by McKinsey & Company indicates that companies employing CNC technology experience a 70% faster time-to-market for new products, allowing them to adapt to changing consumer demands swiftly. This agility promotes not just economic growth but also a more responsive manufacturing ecosystem.

**Tips:** Investing in training for operators can significantly improve both skill levels and operational efficiency, leading to better utilization of CNC technology. Additionally, exploring advanced software solutions can help in optimizing machining processes and reducing energy consumption, further supporting sustainable practices.

Future Trends in CNC Machining: Automation, AI, and Industry 4.0 Integration

The landscape of CNC machining is rapidly evolving, driven by advancements in automation, artificial intelligence, and the integration of Industry 4.0 principles. According to a recent report by McKinsey, about 70% of manufacturers are expected to adopt AI technologies in their operations by 2025, significantly boosting efficiency and precision in production processes. This shift not only streamlines workflows but also enhances the customization capabilities required to meet the rising demands of innovative industries, such as aerospace and healthcare.

Tips: Embracing AI in CNC machining can lead to predictive maintenance, reducing downtime and increasing productivity. Companies should consider investing in AI-driven software solutions that optimize their machining parameters in real-time.

Moreover, the incorporation of Industry 4.0 technologies—such as the Internet of Things (IoT) and big data analytics—enables manufacturers to achieve unprecedented levels of automation. A report by Statista predicts that the global market for advanced manufacturing technologies, including CNC machining integrated with IoT, will reach approximately $267 billion by 2026. This trend enhances not only operational efficiency but also data collection for continuous improvement.

Tips: To stay competitive, manufacturers should focus on training their workforce in new technologies and fostering a culture of innovation to harness the full potential of automation and AI in CNC machining.

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

Future Trends in CNC Machining: Automation, AI, and Industry 4.0 Integration

| Trend | Description | Impact | Example Application |

|---|---|---|---|

| Automation | Integration of automated systems to increase efficiency and reduce human error. | Higher production rates and improved accuracy in manufacturing processes. | Automated CNC machining centers in automotive parts production. |

| Artificial Intelligence | Utilization of AI algorithms to optimize machining processes and predict maintenance needs. | Increased uptime and reduced operational costs. | AI-driven systems for adaptive manufacturing in aerospace components. |

| Industry 4.0 | Creation of smart factories that leverage IoT devices and cloud computing. | Seamless data exchange for enhanced decision-making and agility. | CNC systems connected to the Internet for real-time monitoring and analytics. |

| Sustainability | Focus on environmentally friendly manufacturing practices and reduction of waste. | Positive brand image and compliance with environmental regulations. | Use of recycled materials in precision engineering projects. |

Related Posts

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

The Future of Precision Machining Innovations Transforming Industry Standards

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.