The Future of Precision Machining Innovations Transforming Industry Standards

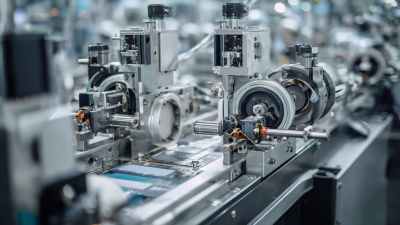

The evolution of precision machining is at the forefront of transforming industry standards, with innovations that redefine efficiency and accuracy in manufacturing processes. According to a recent report by the International Federation of Robotics, the global market for precision machining is projected to reach $173 billion by 2026, driven by advancements in automation and smart manufacturing technologies. As industries increasingly demand higher precision and reduced lead times, precision machining techniques such as CNC machining and additive manufacturing are becoming essential.

These innovations not only enhance production capabilities but also ensure that companies remain competitive in a rapidly changing market. This article explores the latest trends and technologies in precision machining that are shaping the future of manufacturing, highlighting their impact on productivity, quality, and sustainability.

Emerging Technologies Shaping Precision Machining in the 21st Century

The rapid evolution of precision machining in the 21st century is largely driven by emerging technologies that are revolutionizing traditional manufacturing processes. Advanced technologies such as automation, artificial intelligence, and additive manufacturing are reshaping the landscape of precision machining. Automation enables factories to operate with improved efficiency and reduced human error, allowing for higher precision in complex machining tasks. Meanwhile, AI algorithms analyze vast amounts of production data to optimize machining parameters in real-time, leading to enhanced precision and reduced waste.

Furthermore, the integration of additive manufacturing techniques, such as 3D printing, is transforming how parts are designed and produced. By allowing for the creation of complex geometries that are difficult to achieve through conventional methods, additive manufacturing opens new avenues for innovation in precision machining. As industries continue to explore these technologies, the focus shifts towards creating more sustainable and cost-effective production methods, ensuring that precision machining not only meets current demands but also anticipates future challenges in an ever-evolving market.

The Future of Precision Machining Innovations Transforming Industry Standards

| Technology | Description | Impact on Industry | Adoption Rate (%) | Future Potential |

|---|---|---|---|---|

| IoT Integration | Utilizing Internet of Things to enhance machine monitoring and data collection. | Improved efficiency and predictive maintenance capabilities. | 75 | High |

| Additive Manufacturing | 3D printing technology applied to metal and plastic components. | Reduced material waste and design flexibility. | 60 | Growing |

| Artificial Intelligence | AI-driven analytics to optimize machining processes. | Enhanced decision-making and reduced downtime. | 50 | High |

| Advanced Materials | Development of new materials with superior properties. | Enhanced performance and durability of machined parts. | 55 | Medium |

| Robotics Automation | Use of robots for repetitive and complex machining tasks. | Increased production speed and precision. | 70 | Promising |

The Role of AI and Machine Learning in Enhancing Manufacturing Efficiency

The integration of artificial intelligence (AI) and machine learning (ML) in the manufacturing sector is rapidly reshaping industry standards. By leveraging advanced algorithms and data analytics, manufacturers are optimizing processes and enhancing production efficiency like never before. Recent projections estimate that the global AI in manufacturing market will soar to $155.04 billion by 2030, indicating a robust shift towards digitized production models. This technological transformation is evident in various sectors, from food production to semiconductor manufacturing, where AI streamlines operations and improves quality control.

AI's role in enhancing manufacturing efficiency manifests through automation, predictive maintenance, and AI-driven quality assurance protocols. These innovations allow manufacturers to reduce waste and operational costs while maintaining high output quality. With increasing adoption rates, as noted in recent surveys, nearly total integration of AI technologies is on the horizon, streamlining operations and positioning industries for sustainable growth. The ongoing development of smart applications showcases AI as a vital force in driving the future of precision machining and overall manufacturing excellence.

Sustainability Trends in Precision Machining: A Path Forward

In the rapidly evolving field of precision machining, sustainability has emerged as a pivotal trend reshaping industry practices. As manufacturers face increasing pressure to reduce their environmental impact, innovative approaches are being adopted to ensure that machining processes are not only efficient but also eco-friendly. Techniques such as using biodegradable cutting fluids, implementing energy-efficient machinery, and recycling scrap materials are becoming standard practices, contributing significantly to reducing the overall carbon footprint of manufacturing operations.

Moreover, advancements in technology play a critical role in enhancing sustainability in precision machining. The integration of smart manufacturing systems allows for real-time monitoring and optimization of processes, leading to minimized waste and energy consumption. Additionally, the rise of additive manufacturing opens new avenues for reducing material usage while maintaining precision. As these sustainability trends gain momentum, the industry is likely to witness a paradigm shift, where environmental considerations become as essential as precision and productivity, ultimately driving competitive advantages for those who embrace these changes.

Innovative Materials and Processes Revolutionizing Machining Techniques

Innovative materials and processes are critically reshaping the landscape of precision machining, driving advancements that align with modern industrial needs. In recent years, the integration of bio-based materials such as starch into manufacturing processes has gained significant traction. These innovations not only improve efficiency but also support sustainability goals within the industry. For example, advancements in green material usage have led to a reduction in carbon footprints, addressing the pressing demand for eco-friendly solutions. Reports reveal that industries leveraging such materials can lower emissions by up to 30%, showcasing the substantial impact of these innovations.

Moreover, the evolution of machining techniques, influenced by cutting-edge technologies, has transformed traditional workflows. Automation and smart manufacturing systems are streamlining operations, allowing for tighter tolerances and enhanced product quality. With the global market for precision machining projected to reach $100 billion by 2025, it's evident that the blend of innovative materials and high-tech processes is establishing new benchmarks in efficiency and sustainability. As the industry continues to embrace these changes, it holds the promise of not only improving productivity but also contributing meaningfully to the green transition in manufacturing.

Integrating IoT Solutions for Real-Time Monitoring in Precision Manufacturing

The integration of IoT solutions in precision manufacturing is revolutionizing the industry by enabling real-time monitoring and enhancing operational efficiency. As machinery becomes increasingly interconnected, manufacturers can gather and analyze data instantaneously, allowing for immediate adjustments in the production process. This connectivity not only helps to optimize performance but also minimizes downtime and reduces waste, as potential issues can be identified and rectified before they escalate into costly problems.

Furthermore, IoT-enabled devices facilitate improved communication between machines and operators, creating a more cohesive production environment. Through the use of smart sensors and analytics, manufacturers can monitor not just equipment performance, but also environmental conditions and product quality. This real-time feedback loop empowers companies to make data-driven decisions, ensuring that they remain competitive in a fast-evolving market. Ultimately, the incorporation of IoT solutions in precision machining is setting new industry standards that prioritize efficiency, quality, and sustainability.

The Future of Precision Machining: Innovations Transforming Industry Standards

This bar chart illustrates the annual growth rate of precision machining innovations from 2018 to 2023, highlighting the transformative impact of integrating IoT solutions for real-time monitoring in precision manufacturing. The data indicates a steady increase in growth, reflecting the industry's adaptation to new technologies.

Related Posts

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.