How to Improve Efficiency in Machining and Manufacturing Processes

In today's competitive landscape, enhancing efficiency in machining and manufacturing processes has become a paramount objective for industries seeking to optimize productivity and reduce costs. As technology advances and consumer demands evolve, manufacturers are tasked with the challenge of adapting their operations to not only meet these demands but also to streamline workflows. The integration of innovative techniques, automation, and data-driven decision-making can significantly improve the effectiveness of machining and manufacturing, enabling companies to achieve higher quality outputs in less time.

Understanding the intricacies of machining and manufacturing processes is essential for identifying areas ripe for improvement. By analyzing the entire production cycle, from design and material selection to machining techniques and final assembly, manufacturers can uncover inefficiencies and implement strategies that enhance operational performance. Concepts such as lean manufacturing and continuous improvement are critical in fostering an environment where efficiency thrives.

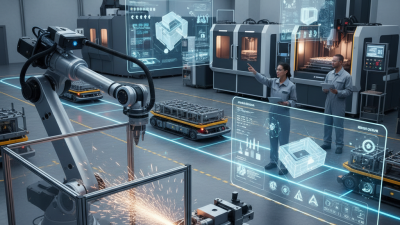

As industries continue to embrace Industry 4.0 principles, the fusion of smart technologies and traditional manufacturing practices is paving the way for unprecedented advancements. The evolution of machining and manufacturing not only demands a reevaluation of existing practices but also encourages a proactive approach towards adopting new tools and methodologies. This exploration into improving efficiency is crucial for manufacturers aiming to maintain competitiveness in an ever-changing market.

Understanding Key Metrics in Machining and Manufacturing Efficiency

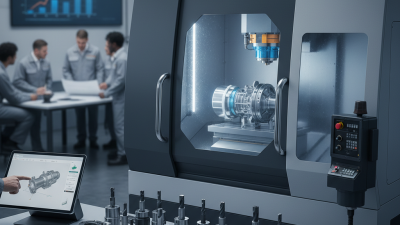

In the quest for improved efficiency in machining and manufacturing processes, understanding key metrics is crucial. One of the primary metrics to monitor is Overall Equipment Effectiveness (OEE). According to a study by the Association for Manufacturing Technology, companies that achieve an OEE score of 85% can significantly outperform their competitors, as this score reflects optimal performance, availability, and quality. In manufacturing environments, a standard OEE target is around 60%, which indicates that many facilities have substantial room for improvement.

Another essential metric is cycle time, which measures the total time from the start to the completion of a machining process. Research conducted by the Manufacturing Engineering Society found that by reducing cycle times by just 10%, manufacturers can enhance their throughput and responsiveness to market demands. Moreover, incorporating tools such as real-time data analytics can offer insights into bottlenecks and inefficiencies in workflows, allowing companies to make data-driven decisions that lead to streamlined operations.

Additionally, scrap rate is a critical metric that impacts both cost and productivity. A report from the National Institute of Standards and Technology indicates that reducing scrap rates by 1% can lead to an increase in profit margins by approximately 2%. By continuously monitoring and optimizing these key performance indicators, manufacturers can create a more efficient production process that not only meets quality standards but also boosts profitability and sustainability in the long term.

Identifying Bottlenecks in Current Processes

Identifying bottlenecks in current machining and manufacturing processes is critical for enhancing efficiency. These bottlenecks often occur at various stages, including material handling, machinery operation, and production flow. A thorough analysis of each stage can reveal inefficiencies, such as excessive downtime of equipment, inadequate workforce allocation, or suboptimal workflow design. By utilizing techniques such as value stream mapping, manufacturers can visualize the entire production process, identify areas of waste, and prioritize interventions that can streamline operations.

Once the bottlenecks are identified, targeted measures can be implemented to alleviate these constraints. For instance, introducing automation in repetitive tasks can significantly reduce cycle times and free up human resources for more complex operations. Additionally, performance metrics should be established to continuously monitor these processes, ensuring that any future bottlenecks are detected and addressed promptly.

Engaging employees in this process is also vital, as their hands-on experience can provide invaluable insights into the challenges faced on the shop floor. By fostering a culture of continuous improvement and open communication, organizations can systematically enhance their operational efficiency.

Implementing Lean Manufacturing Principles for Efficiency

Implementing lean manufacturing principles is a proven approach to enhance efficiency in machining and manufacturing processes. Lean manufacturing focuses on minimizing waste while maximizing productivity, creating a streamlined workflow that leads to cost savings and improved quality. According to a report by the Lean Enterprise Institute, companies that have adopted lean methodologies have experienced an average of 25% reduction in lead times and a 30% increase in overall equipment effectiveness (OEE). This remarkable uplift is achieved through practices such as value stream mapping, continuous improvement, and just-in-time production, all of which foster a culture of efficiency.

A critical aspect of lean principles is the identification and elimination of non-value-added activities. Manufacturing processes often include stages that do not contribute directly to the finished product, such as excessive handling, waiting times, or unnecessary inventory. By employing tools like 5S (Sort, Set in order, Shine, Standardize, Sustain), organizations can create a more organized workplace, leading to improved safety and morale. An Industry Week study found that companies implementing 5S saw up to a 40% improvement in productivity within the first year. Additionally, embracing a culture of continuous improvement enables teams to regularly assess their processes and make incremental changes that collectively lead to significant advancements in efficiency.

How to Improve Efficiency in Machining and Manufacturing Processes - Implementing Lean Manufacturing Principles for Efficiency

| Process | Efficiency Improvement (%) | Lean Principle Applied | Cycle Time Reduction (minutes) |

|---|---|---|---|

| CNC Machining | 30% | Value Stream Mapping | 15 |

| Assembly Line | 25% | 5S Methodology | 10 |

| Welding | 20% | Kaizen Events | 12 |

| Quality Control | 15% | Root Cause Analysis | 8 |

| Inventory Management | 28% | Just-In-Time (JIT) | 5 |

Leveraging Technology and Automation in Production

The integration of technology and automation in machining and manufacturing processes has become a critical pillar for improving efficiency. According to a report by McKinsey & Company, the adoption of advanced manufacturing technologies, including robotics and AI-driven systems, can enhance productivity by up to 30%. This advancement allows manufacturers to optimize their operations, minimize human error, and ensure consistent quality in their products.

Furthermore, the utilization of IoT (Internet of Things) techniques facilitates real-time monitoring of machinery, enabling predictive maintenance and reducing downtime. A study by the World Economic Forum indicates that smart factories leveraging IoT and automation can lead to a 15% reduction in costs and a 20% increase in production speed. By adopting these technologies, manufacturers can make data-driven decisions that significantly streamline workflows and respond more rapidly to market demands. Emphasizing technology in production processes not only improves efficiency but also positions firms to compete more effectively in a dynamic global market.

Training and Skill Development for Workforce Optimization

Training and skill development are crucial elements in optimizing the workforce within machining and manufacturing processes. By investing in continuous education and hands-on training, organizations can enhance the capabilities of their employees. This not only leads to improved operational efficiency but also fosters a culture of innovation and adaptability. Implementing structured training programs that address both technical skills and soft skills can prepare workers to handle the complexities of modern manufacturing environments, enabling them to operate advanced machinery and embrace new technologies effectively.

Furthermore, workforce optimization can be significantly enhanced through mentorship and knowledge-sharing initiatives. Experienced staff can guide newer employees, providing invaluable insights that accelerate learning curves and reduce errors. Encouraging collaboration and peer-to-peer learning helps to build a more cohesive team, ultimately resulting in a more productive workforce. Additionally, regular assessments can identify skill gaps and training needs, allowing for targeted upskilling that aligns with evolving industry demands and technological advancements. Emphasizing ongoing development ensures that the workforce remains competitive, adaptable, and prepared to meet the challenges of a dynamic manufacturing landscape.

Related Posts

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

How to Choose the Best Precision Machining and Manufacturing Services for Your Business Needs

-

Top 10 Advancements in Machining Technology You Need to Know About

-

10 Essential Tips for Choosing the Right Machine Tool in CNC

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.