Why Machining and Manufacturing Are Crucial for Modern Industrial Success

In today’s rapidly evolving industrial landscape, the significance of machining and manufacturing cannot be overstated. Reports indicate that the global manufacturing sector is projected to reach a staggering $44 trillion by 2025, with machining processes playing a pivotal role in this growth. Machining and manufacturing are not only fundamental to producing accurate, high-quality parts but are also integral to fostering innovation and sustainability within various industries.

The increasing complexity of modern products necessitates advanced machining techniques that ensure precision and efficiency. According to a recent study by the National Association of Manufacturers (NAM), manufacturing accounts for 8.5% of the U.S. GDP and supports millions of jobs, illustrating the sector's profound impact on the economy. This vitality highlights the need for businesses to invest in cutting-edge machining technologies and skilled workforce development to remain competitive in the global market.

Furthermore, as industries pivot toward automation and smart manufacturing solutions, the reliance on effective machining and manufacturing strategies has become even more pronounced. The World Economic Forum projects that by 2025, the manufacturing job sector will experience a significant shift, with nearly 70% of new manufacturing jobs requiring specific technical skills. This evolution marks a critical moment for investment in machining and manufacturing, not only to sustain productivity but also to drive future innovations that can usher in a new era of industrial success.

The Role of Machining in Enhancing Precision and Quality in Production

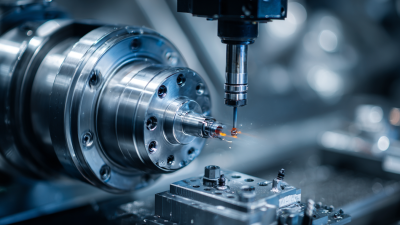

Machining plays a pivotal role in modern manufacturing, serving as the backbone for precision and quality in production processes. Through advanced techniques such as CNC machining, industries can achieve remarkably tight tolerances, which are essential for components utilized in the aerospace, automotive, and medical sectors. These industries demand high precision due to the critical nature of their applications, where even the smallest error can lead to significant failures. The ability to consistently produce parts with exact specifications is what sets competitive manufacturers apart.

Moreover, the integration of sophisticated machining technologies enhances overall production quality. Automated systems minimize human error and ensure repeatability, leading to higher product integrity. As materials continue to evolve, the ability to machine complex geometries with various hardness levels is crucial. This adaptability not only improves product performance but also optimizes manufacturing efficiency, reducing waste and production time. As markets become increasingly competitive, the significance of machining in delivering high-quality products cannot be overstated, making it an essential facet of modern industrial success.

Moreover, the integration of sophisticated machining technologies enhances overall production quality. Automated systems minimize human error and ensure repeatability, leading to higher product integrity. As materials continue to evolve, the ability to machine complex geometries with various hardness levels is crucial. This adaptability not only improves product performance but also optimizes manufacturing efficiency, reducing waste and production time. As markets become increasingly competitive, the significance of machining in delivering high-quality products cannot be overstated, making it an essential facet of modern industrial success.

Manufacturing Techniques That Drive Innovation in Modern Industries

Manufacturing techniques play a pivotal role in driving innovation across modern industries. With the emergence of advanced technologies such as additive manufacturing, CNC machining, and automation, companies can produce complex components with unprecedented precision and efficiency. These innovations not only reduce lead times but also lower production costs, allowing businesses to remain competitive in a rapidly evolving marketplace. Techniques like 3D printing, for instance, enable the rapid prototyping of parts, fostering a culture of experimentation and creativity in product development.

Moreover, the integration of smart manufacturing practices, including the Internet of Things (IoT) and data analytics, empowers manufacturers to optimize their operations in real-time. By leveraging data-driven insights, companies can enhance quality control, streamline supply chains, and predict maintenance needs, which ultimately leads to increased productivity. This synergy between advanced manufacturing techniques and digital technologies positions organizations to respond swiftly to market demands and customize products to meet specific customer needs, thus driving sustained innovation and growth in modern industries.

The Impact of Technological Advancements on Machining Efficiency

Technological advancements have revolutionized the machining and manufacturing sectors, significantly enhancing efficiency and productivity. Automation, powered by artificial intelligence and machine learning, allows for the optimization of machining processes through real-time monitoring and adjustments. This minimizes human error, reduces waste, and increases the speed of production cycles, enabling manufacturers to meet changing market demands swiftly.

Additionally, innovative materials and cutting techniques have emerged, further pushing the boundaries of what machining can achieve. High-speed machining and additive manufacturing technologies have enabled the production of complex geometries with greater precision and less material waste. These advancements not only improve product quality but also expand the scope of design possibilities, empowering industries to innovate and create more sophisticated products than ever before. As a result, companies that embrace these technologies are better positioned to compete in the fast-paced industrial landscape.

Machining Efficiency Over the Years

This chart illustrates the improvements in machining efficiency from 2010 to 2023, highlighting the impact of technological advancements. The data shows significant progress in efficiency improvements as a result of innovations in machinery, automation, and material sciences.

Sustainability in Manufacturing: Balancing Profitability and Environmental Responsibility

Sustainability in manufacturing has become a pressing concern for industries worldwide. As businesses strive to stay profitable, they are also confronted with the growing demand for environmentally responsible practices. This dual challenge requires manufacturers to innovate in their processes, focusing on reducing waste and minimizing carbon footprints while maintaining productivity. By implementing sustainable machining techniques and embracing advanced technologies, companies can achieve significant energy savings and resource optimization.

Moreover, balancing profitability with environmental responsibility is not merely a regulatory obligation—it can also enhance a company's reputation and bottom line. Consumers are increasingly favoring brands that demonstrate commitment to sustainability, driving companies to adopt greener practices. Investing in eco-friendly materials and energy-efficient machinery not only reduces operational costs but also opens up new market opportunities. By aligning their manufacturing processes with sustainability goals, businesses can create a competitive advantage while contributing to a healthier planet.

Why Machining and Manufacturing Are Crucial for Modern Industrial Success - Sustainability in Manufacturing: Balancing Profitability and Environmental Responsibility

| Dimension | Description | Value |

|---|---|---|

| Energy Consumption | Total energy used in manufacturing processes | 500,000 kWh/year |

| Carbon Emissions | CO2 emissions generated from production | 250 tons/year |

| Waste Reduction (%) | Percentage of waste reduced through recycling and efficiency | 30% |

| Profit Margin (%) | Profitability after accounting for sustainability investments | 15% |

| Employee Training Hours | Hours invested in training employees on sustainable practices | 1,200 hours/year |

The Future of Machining and Manufacturing: Trends that Shape Industry Growth

The future of machining and manufacturing is undeniably shaped by various emerging trends that influence industry growth. As the global market for manufacturing machinery continues to expand, driven by technological advancements and increasing demand across sectors such as pharmaceuticals, food and beverage, and mining, the need for precision and efficiency is more critical than ever. With projections indicating substantial growth in associated markets, companies must embrace innovation to stay competitive.

Tips: Emphasizing automation and digital transformation can significantly enhance operational efficiency. Businesses should consider investing in advanced machinery and smart technologies to streamline processes and reduce costs while maintaining high-quality standards. Furthermore, fostering a culture of continuous improvement will help organizations adapt to the ever-changing landscape of manufacturing.

Another trend influencing the future is the rising importance of sustainability in manufacturing processes. As industries strive to minimize their environmental impact, adopting eco-friendly practices and materials will not only meet regulatory requirements but also attract environmentally conscious consumers. Companies should explore sustainable sourcing and waste reduction techniques to build a resilient and responsible manufacturing framework.

Related Posts

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.