Top Machining Equipment Trends to Watch in 2025 for Industry Leaders

As we look toward 2025, the machining equipment industry is poised for transformative changes driven by technological advancements and evolving market demands. According to a recent report by MarketsandMarkets, the global machining equipment market is projected to reach $100 billion by 2025, with a compound annual growth rate (CAGR) of 6.5% during the forecast period. This growth is fueled by the increasing automation and digitalization trends that are reshaping manufacturing processes across various sectors.

Experts in the field highlight the significance of embracing innovation in machining equipment. Johnathan M. Stirling, a renowned machining technology analyst, emphasizes, "The future of machining equipment lies in its ability to adapt and integrate cutting-edge technologies, such as AI and IoT, to enhance precision and efficiency." As industry leaders prepare to navigate these shifts, it becomes essential to stay informed about the latest trends that can impact operational performance and competitive edge.

In this context, understanding the emerging technologies, sustainability practices, and workforce implications will be crucial for organizations aiming to thrive in the dynamic landscape of machining equipment. The following sections will delve into the key trends that industry leaders should watch closely as we approach the mid-2020s.

Emerging Technologies in Machining Equipment for 2025

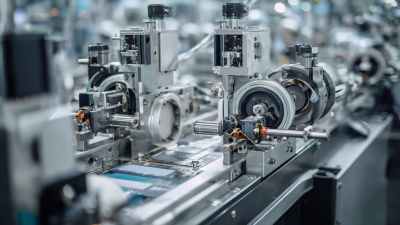

As we approach 2025, several emerging technologies in machining equipment stand out, poised to reshape the industry landscape. One of the most notable trends is the integration of artificial intelligence and machine learning algorithms into machining processes. According to a recent industry report, companies that adopt AI-driven technologies can improve operational efficiency by up to 30%. These advancements allow for predictive maintenance, optimizing machine performance and reducing downtime, which is critical for maintaining competitive advantage in a fast-paced market.

Another key development to watch is the rise of advanced materials in machining applications. With the demand for lighter, stronger components in industries such as aerospace and automotive, materials like carbon fiber and titanium are becoming more prevalent. Reports indicate that the global market for advanced materials is expected to reach $170 billion by 2025, driving innovations in machining equipment that can handle these challenging materials effectively. This shift not only enhances product strength but also contributes to sustainability, as lightweight materials can improve fuel efficiency in transportation.

Tips: When considering upgrades to your machining equipment, focus on versatility. Equipment that can adapt to different materials and processes will provide greater return on investment. Additionally, investing in training for your workforce on new technologies can significantly improve productivity and safety. Staying informed about cutting-edge advancements will ensure you remain a leader in your field.

Top Machining Equipment Trends to Watch in 2025

This bar chart illustrates the anticipated growth rates of key machining equipment trends in 2025, highlighting the impact of emerging technologies such as automation, IoT integration, and advanced materials.

Sustainability Practices in the Machining Industry

The machining industry is undergoing a significant transformation as sustainability practices gain traction. Industry leaders are increasingly adopting eco-friendly processes and technologies, aiming to reduce waste, enhance energy efficiency, and minimize their carbon footprint. This shift not only complies with regulatory standards but also addresses growing consumer demand for sustainable practices. By integrating sustainable solutions, companies can increase their operational efficiency while simultaneously engaging in environmental stewardship.

Tips for implementing sustainability practices include conducting a thorough audit of current processes to identify areas for improvement. Consider investing in energy-efficient machinery and tools that reduce power consumption. Moreover, incorporating recycling programs and utilizing biodegradable materials can significantly decrease waste output. Training employees on sustainability initiatives fosters a culture of environmental awareness, ensuring that everyone contributes to the company’s eco-friendly goals.

As the industry moves towards greener operations, leveraging technology such as IoT for real-time monitoring can optimize resource utilization. Additionally, collaborating with suppliers who prioritize sustainability can create a more responsible supply chain. By prioritizing sustainability, machining companies not only work towards a healthier planet but also enhance their competitive edge and market position.

Automation and AI Integration in Machining Processes

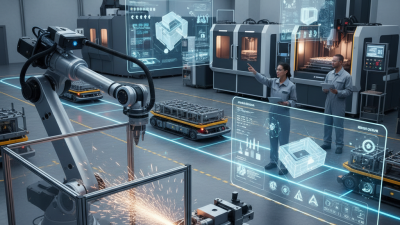

The integration of automation and artificial intelligence (AI) into machining processes is revolutionizing the manufacturing landscape, particularly as we approach 2025. Industry leaders are increasingly adopting these technologies to enhance productivity and precision, allowing for faster turnaround times and improved quality. With the rising complexity of production demands, automation is not just a luxury but a necessity. Robotics are enhancing traditional machining systems, enabling seamless operations that minimize human intervention and maximize efficiency.

Embracing AI within machining processes allows for real-time data analysis, predictive maintenance, and enhanced decision-making capabilities. By implementing AI-driven systems, manufacturers can anticipate equipment failures before they occur, significantly reducing downtime and maintenance costs. This data-driven approach leads to smarter production strategies, aligning with the industry's need for agility in a rapidly changing market.

Tips: To successfully integrate automation and AI into your machining operations, start with a clear assessment of your current processes. Identify areas where efficiency can be improved and consider incremental changes to ease the transition. Collaborating with technology specialists can also provide valuable insights into selecting the right tools and systems tailored to your specific needs. Prioritize training for your workforce to ensure they can effectively leverage these innovations, thereby maximizing the benefits of a smarter manufacturing environment.

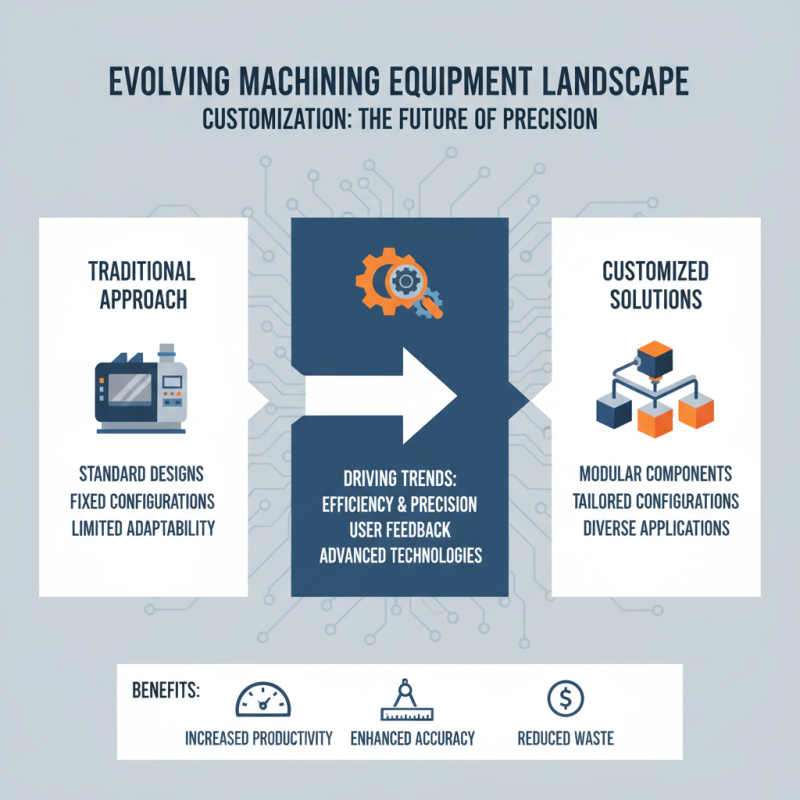

Customization Trends in Machining Equipment Design

The machining equipment landscape is evolving significantly, with customization emerging as a driving trend in design. As industries prioritize efficiency and precision, manufacturers are increasingly tailoring equipment to meet specific customer needs. This shift towards customization allows for machines to be designed with modular components, enabling users to configure setups that align perfectly with their operational requirements. By integrating user feedback and utilizing advanced technologies, today's machining equipment can be adapted for various applications, ensuring optimal performance across diverse sectors.

Moreover, the emphasis on sustainable manufacturing practices has led to further customization in design processes. Equipment that minimizes waste and energy consumption can be tailored to fit unique production methodologies. With advancements in materials science and digital fabrication, manufacturers can create bespoke solutions that not only enhance productivity but also contribute to environmental sustainability. As industry leaders focus on optimizing their operations for both performance and ecological impact, the trend of customization in machining equipment design is set to reshape the future of manufacturing in 2025 and beyond.

Impact of Industry 4.0 on Machining Efficiency and Productivity

The integration of Industry 4.0 technologies is significantly transforming machining processes, enhancing both efficiency and productivity for industry leaders. The adoption of advanced automation, IoT, and data analytics allows manufacturers to optimize operations in real-time. According to a recent report by McKinsey, companies that successfully implement Industry 4.0 principles can expect productivity gains of up to 20-30%. This shift not only streamlines production but also minimizes waste and operational downtime, which are critical factors in maintaining competitiveness in the machining sector.

One key aspect of Industry 4.0's influence on machining efficiency is predictive maintenance. By leveraging IoT sensors and machine learning algorithms, manufacturers can proactively identify equipment issues before they escalate into costly failures. A study from Deloitte indicates that implementing predictive maintenance can reduce machine downtime by as much as 50%. This significant reduction translates directly to increased productivity, allowing businesses to meet their production targets more consistently and effectively.

**Tips:** To stay ahead in the evolving landscape, industry leaders should invest in training programs for their workforce to familiarize them with new technologies. Additionally, establishing a culture of continuous improvement and openness to adopting new tools can significantly enhance a company's ability to thrive amid these shifts. Keeping abreast of technological advancements and industry benchmarks will be critical to maintaining a competitive edge.

Top Machining Equipment Trends to Watch in 2025 for Industry Leaders

| Trend | Impact on Efficiency | Projected Adoption Rate (%) | Expected Benefits |

|---|---|---|---|

| Automation and Robotics | Increases speed and precision | 70% | Reduced labor costs, enhanced scalability |

| Artificial Intelligence | Improves decision-making and predictive maintenance | 65% | Minimized downtime, optimized resources |

| Additive Manufacturing | Enhances design flexibility and reduces material waste | 50% | Customized solutions, lower production costs |

| 3D Printing | Facilitates rapid prototyping and part production | 55% | Speed to market, enhanced innovation |

| IoT Integration | Improves data collection and analysis | 60% | Better asset management, real-time monitoring |

Related Posts

-

Top 10 Advancements in Machining Technology You Need to Know About

-

Top 10 Best Machine Tools for Precision Engineering in 2023

-

How to Improve Efficiency in Machining and Manufacturing Processes

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

-

10 Essential Tips for Choosing the Right Machine Tool for Your Workshop

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.