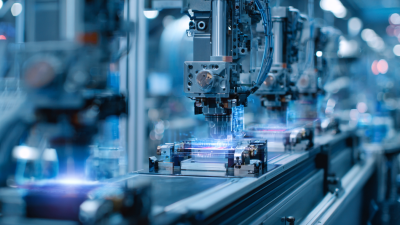

Top Manual Machine Techniques for Efficient Operations and Productivity Boost

In the rapidly evolving landscape of manufacturing and industrial operations, the importance of optimizing efficiency and productivity cannot be overstated. A recent report by the National Association of Manufacturers indicated that nearly 80% of manufacturers believe enhancing productivity is critical for staying competitive in the global market. Among the various approaches to achieving this goal, mastering top manual machine techniques stands out as a vital strategy. Manual machines, when operated effectively, not only increase operational efficiency but also contribute to a significant reduction in waste and production costs.

According to a study published by the Manufacturing Institute, companies that have implemented streamlined manual machine operations have experienced productivity boosts of up to 25%. This is largely attributed to the high level of control and precision that manual machines provide, which is essential in tasks requiring intricate craftsmanship. By leveraging such manual techniques, businesses can not only improve their output but also maintain quality standards that meet or exceed customer expectations. As the industry continues to seek innovative ways to enhance performance, mastering manual machine techniques will remain a cornerstone for companies aspiring to thrive in a competitive market.

Understanding Manual Machine Techniques for Enhanced Productivity

Manual machine techniques play a crucial role in enhancing productivity across various industries. By mastering these techniques, operators can significantly reduce downtime and streamline operations. Understanding the fundamentals of manual machining, including tool selection, maintenance, and workflow optimization, allows workers to perform tasks more efficiently. A skilled operator can effectively maneuver machines with precision, resulting in high-quality outputs and minimized waste.

Moreover, training and continuous learning in manual techniques can lead to improved problem-solving skills and innovation on the shop floor. Familiarity with different machining processes, such as turning, milling, and drilling, empowers operators to make informed decisions that enhance productivity. Implementing best practices, such as maintaining a clean workspace and regular tool inspection, can further contribute to smoother operations and higher output rates. Ultimately, investing in knowledge and application of manual machine techniques is vital for businesses looking to boost their operational efficiency.

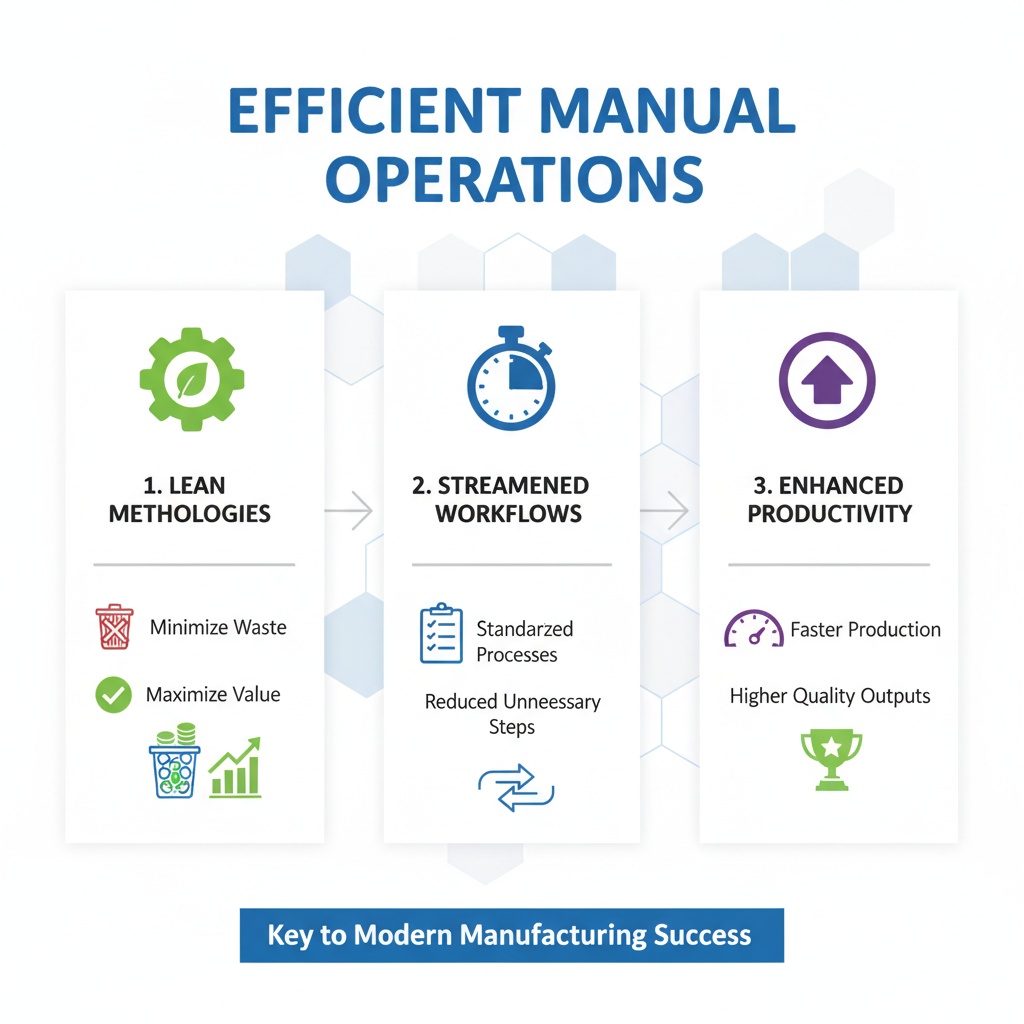

Key Principles of Efficient Manual Operations in Manufacturing

In today's manufacturing landscape, the principles of efficient manual operations are pivotal for enhancing productivity. One fundamental principle is the integration of lean methodologies, which focus on minimizing waste while maximizing value. This can be accomplished through streamlined workflows and standardized processes that prioritize efficiency. By adopting practices that reduce unnecessary steps, companies can not only speed up production but also ensure higher quality outputs.

Another key aspect is the incorporation of digital tools that empower workers. As the trend towards Industry 4.0 continues to grow, manual operations must evolve with technology. Leveraging data analysis and digital solutions enables real-time decision-making, ultimately fostering a more responsive manufacturing environment. Empowering teams with these technologies allows for quicker adjustments to production lines and enhances the overall effectiveness of manual operations, ensuring that businesses remain competitive in a rapidly changing market.

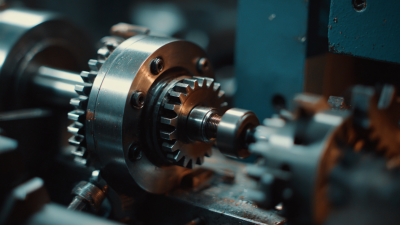

Tools and Equipment for Manual Machine Optimization

When it comes to optimizing manual machine operations, the right tools and equipment play a crucial role. Investing in high-quality machinery and hand tools not only enhances productivity but also ensures safety and precision in every task. For instance, using ergonomic hand tools can significantly reduce strain on workers, leading to fewer injuries and more efficient workflows. Additionally, selecting machines with adjustable settings allows operators to customize their work processes according to specific tasks, further improving efficiency.

**Tips:** Consider implementing a scheduled maintenance program for all equipment. Regular checks and servicing can prevent costly breakdowns and ensure that machines are always in optimal condition. Furthermore, keep your workspace organized and free of clutter. A tidy environment allows for better focus and reduced time lost searching for tools or materials.

Another aspect of manual machine optimization is the use of digital resources, such as software for workload management and tracking. By integrating technology, you can monitor performance, identify bottlenecks, and make data-driven decisions that boost productivity. Efficient operations are not just about the right tools, but also about how well they are utilized in conjunction with smart management strategies.

Top Manual Machine Techniques for Efficient Operations and Productivity Boost - Tools and Equipment for Manual Machine Optimization

| Technique | Description | Benefits | Tools/Equipment | Application Areas |

|---|---|---|---|---|

| Precision Machining | Using manual machines to achieve high precision in components. | Improved accuracy and reduced waste. | Lathes, mills, and calipers. | Aerospace, automotive, and manufacturing. |

| Manual Welding | Using handheld tools for welding metals together. | Versatile applications and lower setup costs. | Welders, torches, and protective gear. | Construction, shipbuilding, and repairs. |

| Assembly Line Techniques | Streamlining processes in manual assembly operations. | Increased throughput and reduced lead times. | Workstations, tools for assembly, and jigs. | Electronics, consumer goods, and appliances. |

| Hand Tool Optimization | Enhancing manual tool usage for efficiency. | Reduced physical strain and increased productivity. | Ergonomic hand tools, tool belts. | Construction, woodworking, and crafts. |

| Quality Control Procedures | Implementing checks during manual processes. | Higher quality output and customer satisfaction. | Measuring instruments, checklists. | Manufacturing, food production, and pharmaceuticals. |

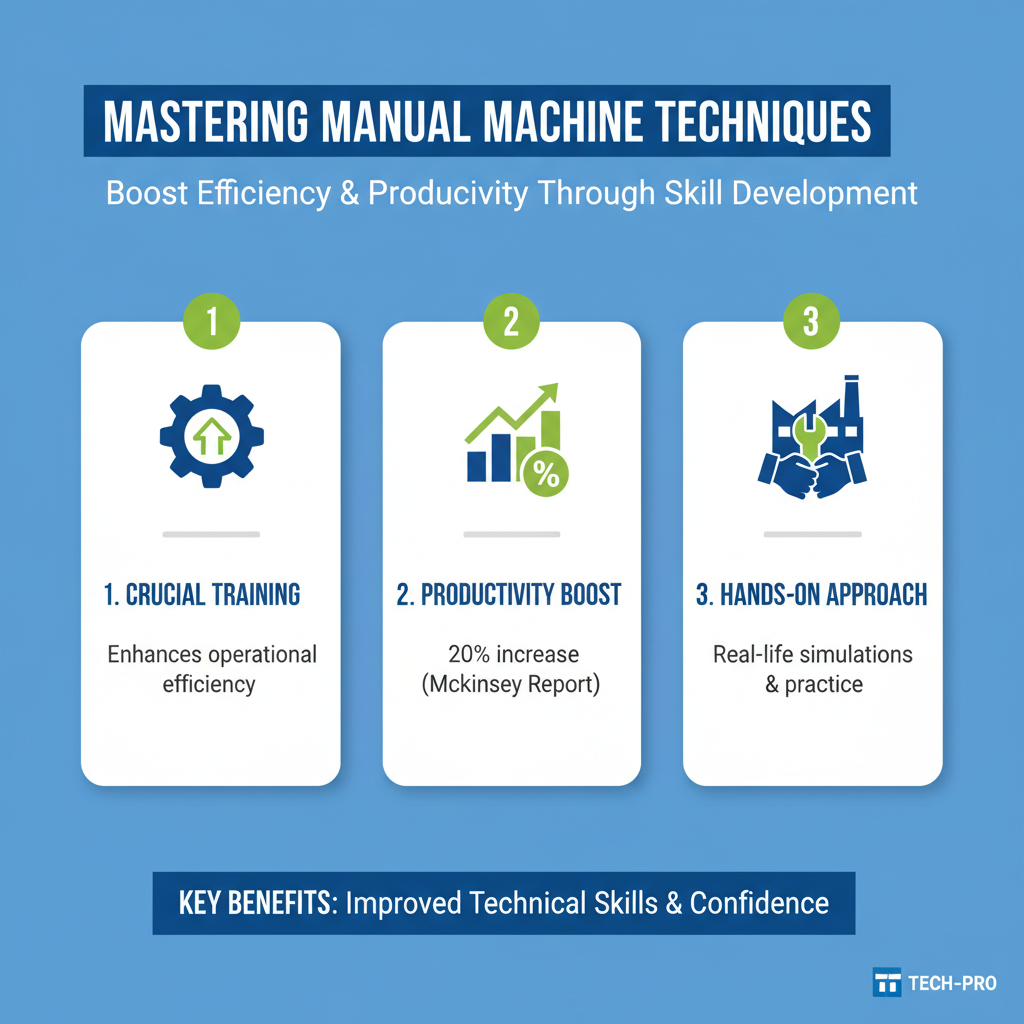

Best Practices for Training and Skill Development

Effective training and skill development are crucial to implementing top manual machine techniques that enhance operational efficiency and productivity. According to a report from the McKinsey Global Institute, companies that invest in skill development can see a 20% increase in productivity within the first year. To maximize these benefits, organizations should focus on hands-on training programs that involve real-life simulations and machine operation practices. This not only boosts employees' technical skills but also fosters confidence in their ability to handle equipment effectively.

Tips for Training: Encourage peer-to-peer mentoring where experienced operators guide newer employees, as this promotes knowledge sharing and accelerates skill acquisition. Furthermore, investing in regular workshops can keep staff updated on the latest techniques and best practices in manual machine operation.

Additionally, the World Economic Forum highlights that up to 40% of workers will need reskilling by 2025 due to technological advancements. Hence, it’s vital to create a continuous learning environment. Incorporating feedback loops allows trainees to refine their skills based on performance insights, which can lead to a more adept workforce equipped to handle future challenges.

Measuring and Analyzing Productivity Gains in Manual Operations

Measuring and analyzing productivity gains in manual operations is essential for enhancing operational efficiency in various industries. By implementing key performance indicators (KPIs) specific to manual processes, organizations can track metrics such as output rates, error frequencies, and time taken for tasks. These measurements provide a clear picture of where inefficiencies lie and help identify areas for improvement. Techniques like time-motion studies can be particularly effective, as they reveal how time is allocated across different tasks and highlight potential bottlenecks in workflows.

Additionally, tools such as observational audits and employee feedback can enrich the analysis of productivity. By engaging frontline workers in discussions about their challenges and experiences, management can uncover insightful perspectives on inefficient practices. Utilizing data analytics software can further enhance this process by consolidating and visualizing productivity data, making it easier to spot trends and anomalies. Ultimately, a robust measuring framework allows organizations to not only assess their current productivity levels but also to implement targeted strategies that lead to sustainable productivity gains in manual operations.

Productivity Gains in Manual Operations

Related Posts

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

-

Top 10 Advancements in Machining Technology You Need to Know About

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

Top 10 Best Machine Tools for Precision Engineering in 2023

-

The Future of Machine Manufacturing Innovations Transforming Industries

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.