2025 How to Optimize CNC Machine Design for Maximum Efficiency and Performance

In an era where precision engineering and efficiency are paramount, optimizing CNC machine design is crucial for manufacturers aiming to enhance performance and productivity. CNC machine design encompasses various aspects, including the selection of materials, component architecture, and control systems that collectively contribute to the machinery's operational capabilities. By understanding the intricacies of CNC machine design, manufacturers can streamline processes, reduce waste, and ultimately achieve superior results in their production lines.

Further exploration into CNC machine design reveals a wealth of opportunities for innovation. Advances in technology and engineering practices allow designers to implement features that not only boost the speed and accuracy of machining operations but also enhance the overall user experience. Focused efforts on refining aspects such as tooling interfaces, thermal management, and automation play a significant role in driving efficiency.

As industries continue to evolve, investing in optimized CNC machine design becomes essential for staying competitive. This comprehensive guide will delve into strategic approaches and best practices that empower manufacturers to optimize their CNC machine design for maximum efficiency and performance, potentially transforming their operational landscapes and setting the stage for sustainable growth.

Understanding CNC Machine Design Principles and their Importance

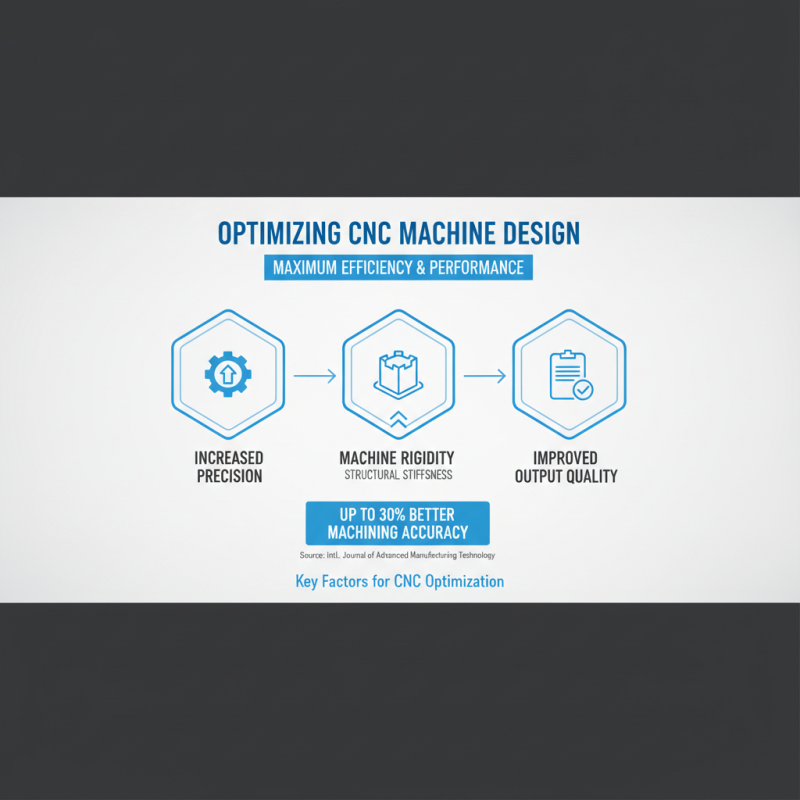

CNC machine design is crucial for achieving optimal efficiency and performance in manufacturing processes. Understanding the fundamental principles of CNC design helps engineers create systems that minimize downtime, enhance precision, and maximize production capabilities. According to a report by the International Federation of Robotics, the integration of advanced CNC technologies has increased productivity by up to 30% in some industries. These figures underline the significance of well-structured design principles that encompass factors such as machine rigidity, thermal stability, and precise control mechanisms.

To further enhance CNC machine efficiency, manufacturers should focus on effective cooling systems, as overheating can lead to tool wear and diminished performance. Implementing advanced software for simulation and modeling can also optimize the design process by predicting potential failures and improving workflow.

**Tips:** Regularly assess the wear and tear on CNC components and implement scheduled maintenance checks to ensure that all systems run smoothly. Additionally, consider investing in training for operators to better utilize machine capabilities, which can contribute to overall performance improvements. Lastly, incorporating real-time data analysis can provide insights that drive design improvements and operational efficiency.

Key Factors Influencing CNC Machine Efficiency and Performance

When optimizing CNC machine design for maximum efficiency and performance, several key factors must be considered. The machine's rigidity, for instance, plays a crucial role in maintaining precision during operation. According to a report by the International Journal of Advanced Manufacturing Technology, a machine's structural stiffness can improve machining accuracy by up to 30%, directly impacting the quality of the output.

Another significant aspect is the choice of materials used in machine construction. Lightweight yet strong materials can reduce the overall weight of the machine, enhancing its operational speed without compromising rigidity. A study conducted by the Machine Tool Technology Association reveals that machines designed with advanced composites can achieve efficiency gains of up to 20% compared to traditional steel constructions.

Tips: To maximize efficiency, ensure regular maintenance of the CNC machine. Investing in high-quality lubrication can greatly reduce friction and wear, leading to prolonged machine life and consistent performance. Additionally, implementing adaptive control systems can dynamically adjust machine parameters in real time, optimizing production flow and reducing downtime.

Another factor influencing CNC machine performance is tooling technology. Utilizing advanced cutting tools with proper geometries can significantly enhance chip removal rates, which accelerates production speed. Data from the Cutting Tool Manufacturers Association indicates that selecting the appropriate cutter can improve material removal rates by as much as 50%, frontloading efficiency into each machining cycle. Implementing these strategies can elevate CNC operations to new heights of effectiveness and productivity.

Advanced Materials and Technologies in CNC Machine Design

The evolution of CNC machine design has been significantly influenced by advanced materials and technologies, aiming to enhance efficiency and performance. One of the key advancements in this area is the integration of lightweight, high-strength materials. These materials not only reduce the overall weight of the machines but also improve their rigidity and durability, which is essential for precision manufacturing. By utilizing composites and specialized alloys, designers can create machines that maintain high performance under varying operational conditions.

Tips for choosing materials include conducting thorough research on the mechanical properties required for specific applications, as this can lead to improved machining speeds and reduced energy consumption. Another consideration is the compatibility of these materials with cutting-edge technologies, such as additive manufacturing, which allows for intricate designs that were previously impossible with traditional methods.

Furthermore, the incorporation of smart technologies into CNC machine design is revolutionizing the industry. Sensors and IoT devices can provide real-time data on machine performance and maintenance needs, allowing for proactive adjustments and minimizing downtime.

Tips for implementing smart technologies suggest starting with modular upgrades to existing systems, ensuring an easier integration process and potentially leading to significant cost savings in the long run. Adopting these innovations can position manufacturers at the forefront of efficiency and productivity in the competitive landscape.

2025 CNC Machine Design Efficiency and Performance Metrics

This chart displays the optimized metrics for CNC machine design in 2025, focusing on key performance indicators such as material utilization, production speed, energy consumption, maintenance time, and cycle time. These metrics are essential for maximizing efficiency and performance in CNC machining processes.

Best Practices for CNC Machine Maintenance and Optimization

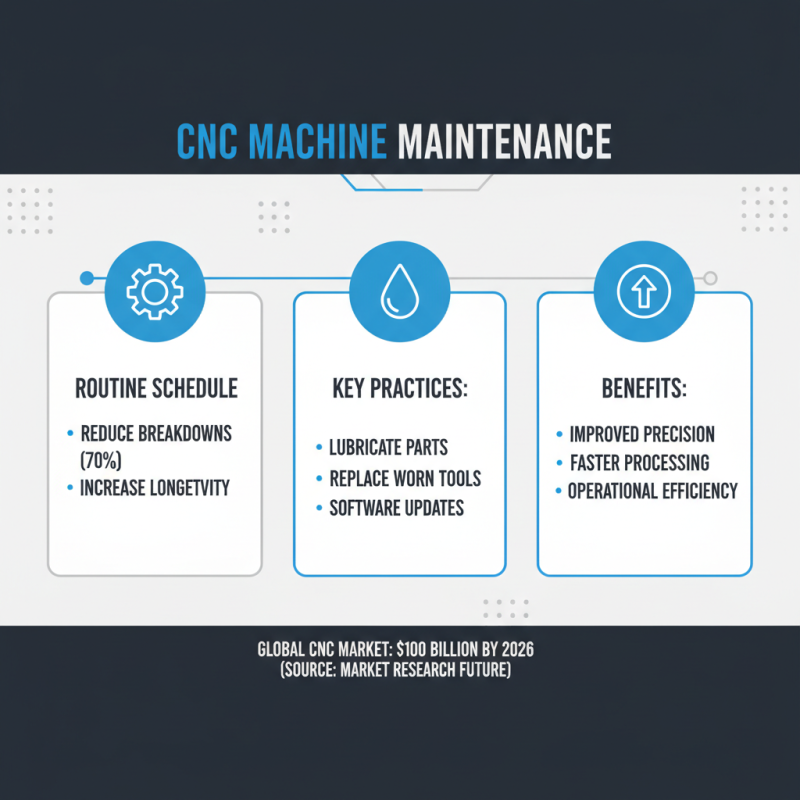

Maintaining and optimizing CNC machines is crucial for ensuring their longevity and operational efficiency. According to a report by Market Research Future, the global CNC machining market is projected to reach USD 100 billion by 2026, highlighting the growing importance of effective machine maintenance practices. Implementing a routine maintenance schedule can significantly reduce the frequency of breakdowns, with studies indicating that regular inspections can prevent approximately 70% of potential machine failures. Key practices include lubricating moving parts, regularly replacing worn-out tools, and keeping the machine’s software updated to allow for improved processing speeds and precision.

In addition to routine maintenance, optimizing CNC machine performance can be achieved through data-driven methodologies. The use of predictive analytics tools enables manufacturers to anticipate maintenance needs and minimize downtime. Research from the National Institute of Standards and Technology (NIST) shows that companies applying predictive maintenance solutions can reduce equipment failures by up to 50%, thus maximizing productivity. Moreover, ensuring proper machine setup, including alignment and calibration, directly affects the performance and quality of the final product. Properly tuned machines contribute to less waste and improved cycle times, creating a more efficient manufacturing environment. These best practices not only enhance machine reliability but also increase overall production efficiency.

Future Trends in CNC Machine Design for Enhanced Productivity

As we look toward the future of CNC machine design, several emerging trends promise to enhance productivity and efficiency significantly. One of the most notable trends is the increased integration of IoT (Internet of Things) technology within CNC systems. By allowing machines to communicate with each other and with centralized monitoring systems, manufacturers can achieve real-time data analysis, predictive maintenance, and automated adjustments. This connectivity not only minimizes downtime but also optimizes workflow processes, leading to higher overall productivity.

Additionally, the adoption of advanced materials and design techniques plays a crucial role in shaping the future of CNC machines. Lightweight, durable materials such as carbon fiber and composites are becoming more prevalent, leading to machines that are easier to operate and maintain while providing enhanced precision. Moreover, additive manufacturing techniques are paving the way for innovative designs that allow for more compact and efficient machine configurations, saving on both materials and operational costs. The combination of these advancements ensures that CNC machines remain at the forefront of industrial production, pushing the boundaries of what is possible in manufacturing.

Related Posts

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Top 10 CNC Machine Tools Every Engineer Should Know in 2023

-

How to Optimize CNC Machining Manufacturing for Maximum Efficiency and Quality

-

2025 How to Achieve High CNC Machining Precision in Manufacturing

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.