How to Optimize CNC Machining Manufacturing for Maximum Efficiency and Quality

In the rapidly evolving landscape of CNC machining manufacturing, optimizing processes for maximum efficiency and quality has become imperative for businesses aiming to maintain a competitive edge. According to Dr. Lisa Harper, a leading expert in CNC machining technologies, “The path to superior efficiency lies in the seamless integration of advanced technologies and skilled craftsmanship.” This insight emphasizes the critical balance that must be struck between leveraging technological advancements and honing the skills of personnel involved in CNC machining manufacturing.

As industries increasingly demand precision and speed, the optimization of CNC machining manufacturing processes is not merely an option but a necessity. Companies are faced with the challenge of reducing cycle times and waste while enhancing the quality of the final products. By implementing best practices, such as predictive maintenance and advanced statistical process control, manufacturers can effectively streamline their operations. This proactive approach not only boosts productivity but also ensures that quality remains consistent, fostering greater customer satisfaction and loyalty.

In conclusion, the optimization of CNC machining manufacturing is essential in today’s competitive market. The insights from experts like Dr. Harper serve as a guiding framework for manufacturers looking to elevate their operational standards. By embracing both innovative technologies and robust training programs, businesses can unlock new levels of efficiency and quality in their CNC machining processes.

Strategies for Reducing CNC Machining Cycle Times by Up to 30%

Reducing CNC machining cycle times by up to 30% is not merely an aspiration; it is achievable through strategic optimization techniques. According to a recent report by the Manufacturing Technology Association, effective implementation of advanced technology can lead to significant reductions in cycle times. For instance, integrating high-speed machining tools can enhance productivity substantially. By utilizing tools with improved cutting speeds and efficiency, manufacturers can decrease processing times while maintaining high levels of accuracy and quality.

Additionally, optimizing the CNC programming process is crucial. A study from the Advanced Manufacturing Research Center indicates that using modern software for toolpath optimization can lead to a reduction in machining time by about 25%. This involves simulating the machining process to identify inefficiencies and refine the tool movement for quicker execution.

Pairing these technical advancements with employee training on best practices in CNC operation further elevates the potential for efficiency, ensuring that skilled operators leverage the equipment to its fullest capacity. These steps collectively establish a framework for maximizing productivity in CNC machining environments.

Implementing Advanced Tooling Techniques to Enhance Precision and Durability

Advanced tooling techniques play a crucial role in optimizing CNC machining processes by enhancing both precision and durability. The implementation of high-quality tooling materials, such as carbide or ceramic, can significantly reduce wear and prolong the lifespan of cutting tools. This ensures that the machining operations maintain a consistent level of precision, resulting in superior quality products. Furthermore, employing specialized coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), can also contribute to the cutting tools' performance by minimizing friction and preventing oxidation, which is particularly beneficial in high-speed applications.

Another effective approach is the integration of advanced geometrical designs in tooling. Custom tool shapes can be engineered to better suit specific machining tasks, leading to improved chip removal and reduced cutting forces. Furthermore, utilizing adaptive tooling systems that can automatically adjust parameters based on real-time feedback results in higher efficiency and a reduction in scrap material. This approach not only increases operational efficiency but also allows for flexible production, enabling manufacturers to respond quickly to varying demands while maintaining the highest standards of quality in their CNC machined components.

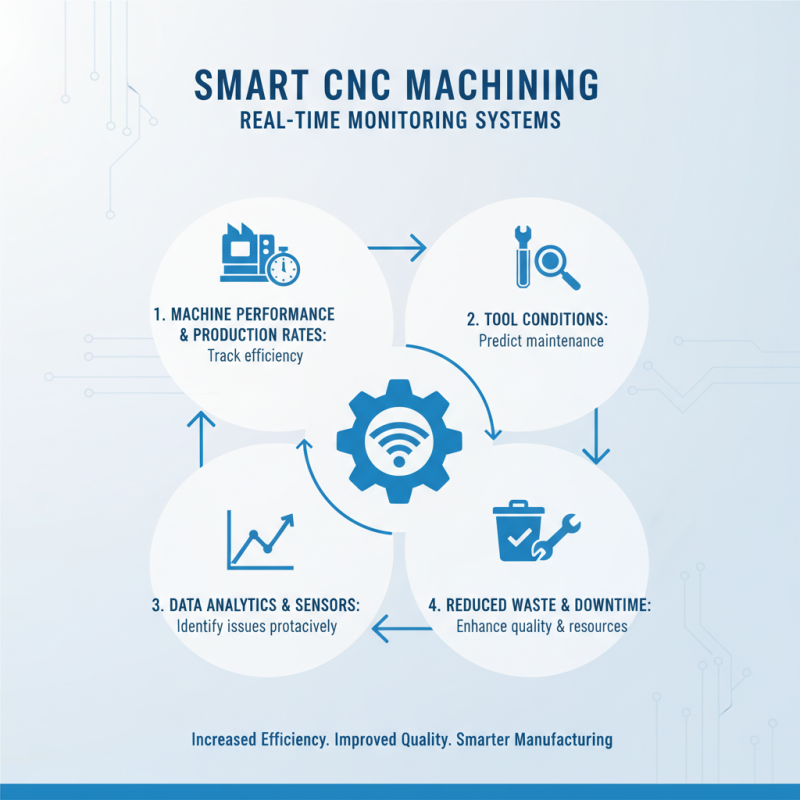

Integrating Real-Time Monitoring Systems to Improve Operational Efficiency

Integrating real-time monitoring systems in CNC machining can significantly enhance operational efficiency and product quality. These systems allow manufacturers to keep track of machine performance, tool conditions, and production rates in real time. By leveraging sensors and data analytics, operators can identify inefficiencies and potential issues before they escalate into costly downtime. This proactive approach not only streamlines the manufacturing process but also reduces waste and rework, ensuring a more effective use of resources.

Moreover, real-time monitoring facilitates data-driven decision-making, enabling manufacturers to optimize their machining parameters dynamically. With continuous feedback on machine status and output quality, adjustments can be made instantly, catering to varying production demands or raw material quality. By harnessing this level of insight, businesses can improve their production timelines and enhance overall product consistency. The result is a manufacturing environment that not only prioritizes efficiency but also upholds high standards of quality through continuous monitoring and evaluation.

Utilizing Statistical Process Control to Minimize Defects and Waste

Utilizing Statistical Process Control (SPC) in CNC machining is a critical strategy for minimizing defects and waste, ultimately leading to enhanced manufacturing efficiency. SPC involves the use of statistical methods to monitor and control a process. By integrating SPC into CNC machining, manufacturers can identify variations in the machining process in real-time, allowing for immediate corrective actions. According to industry reports, companies that implement SPC can expect to see a reduction in scrap rates by up to 30% and an increase in overall productivity by 20%, highlighting its significant impact on operational performance.

Furthermore, SPC fosters a culture of continuous improvement by providing data-driven insights that lead to better decision-making. By analyzing data from CNC machining processes, manufacturers can pinpoint the root causes of defects and categorize them for further investigation. A report from the Institute of Industrial Engineers indicated that manufacturers that actively utilize SPC see a reduction in machine downtime by approximately 25%, as they can better predict tool wear and other performance-related issues. This not only enhances the quality of the final products but also boosts customer satisfaction and competitive advantage in the market.

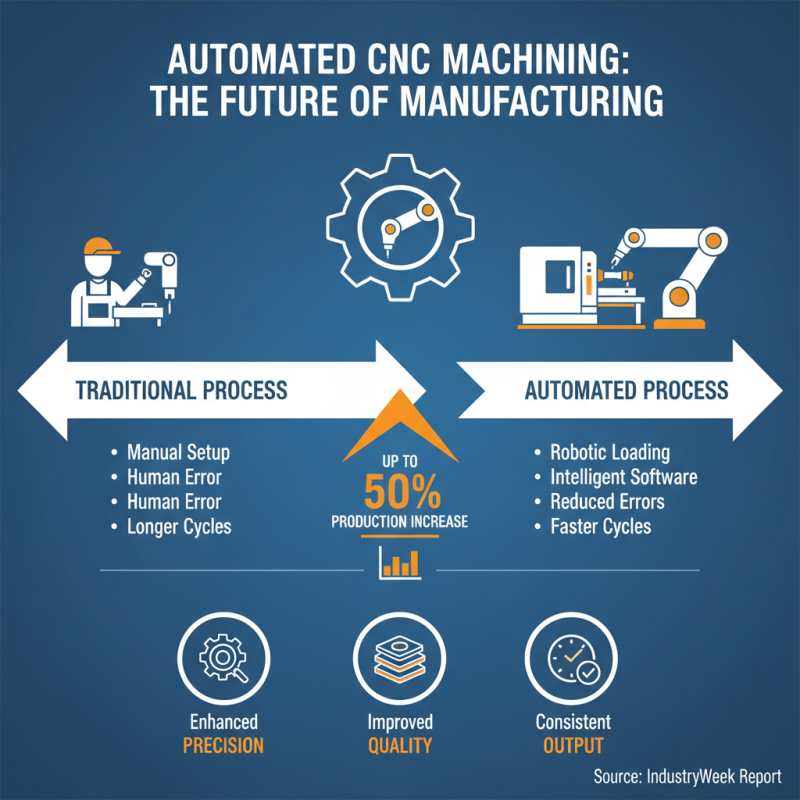

Adopting Automation Solutions to Increase Production throughputs by 50%

In today's highly competitive manufacturing landscape, optimizing CNC machining processes through automation has emerged as a critical strategy to enhance production efficiencies. According to a report by IndustryWeek, adopting automation solutions can increase production throughput by up to 50%, which is a significant boost for manufacturers facing tight margins. Automation technologies, such as robotic arms and intelligent software, streamline operations by minimizing human error, reducing cycle times, and enhancing overall precision. This not only leads to increased output but also improves the consistency and quality of the machined parts.

Additionally, a study from Deloitte highlights that companies that implement advanced manufacturing technologies, including automation, can see a reduction in operational costs by as much as 30%. By integrating automation, manufacturers can optimize resource allocation and shift labor towards more analytical roles, fostering workforce development and innovation. The future of CNC machining lies in leveraging these automation solutions to not only meet increasing consumer demands but also to ensure sustainability and competitiveness in the market. Embracing these advancements is essential for manufacturers aiming to thrive in an ever-evolving industrial environment.

Related Posts

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

2025 How to Achieve High CNC Machining Precision in Manufacturing

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.