Unlocking Precision in Manufacturing with the Latest Tool CNC Machine Innovations

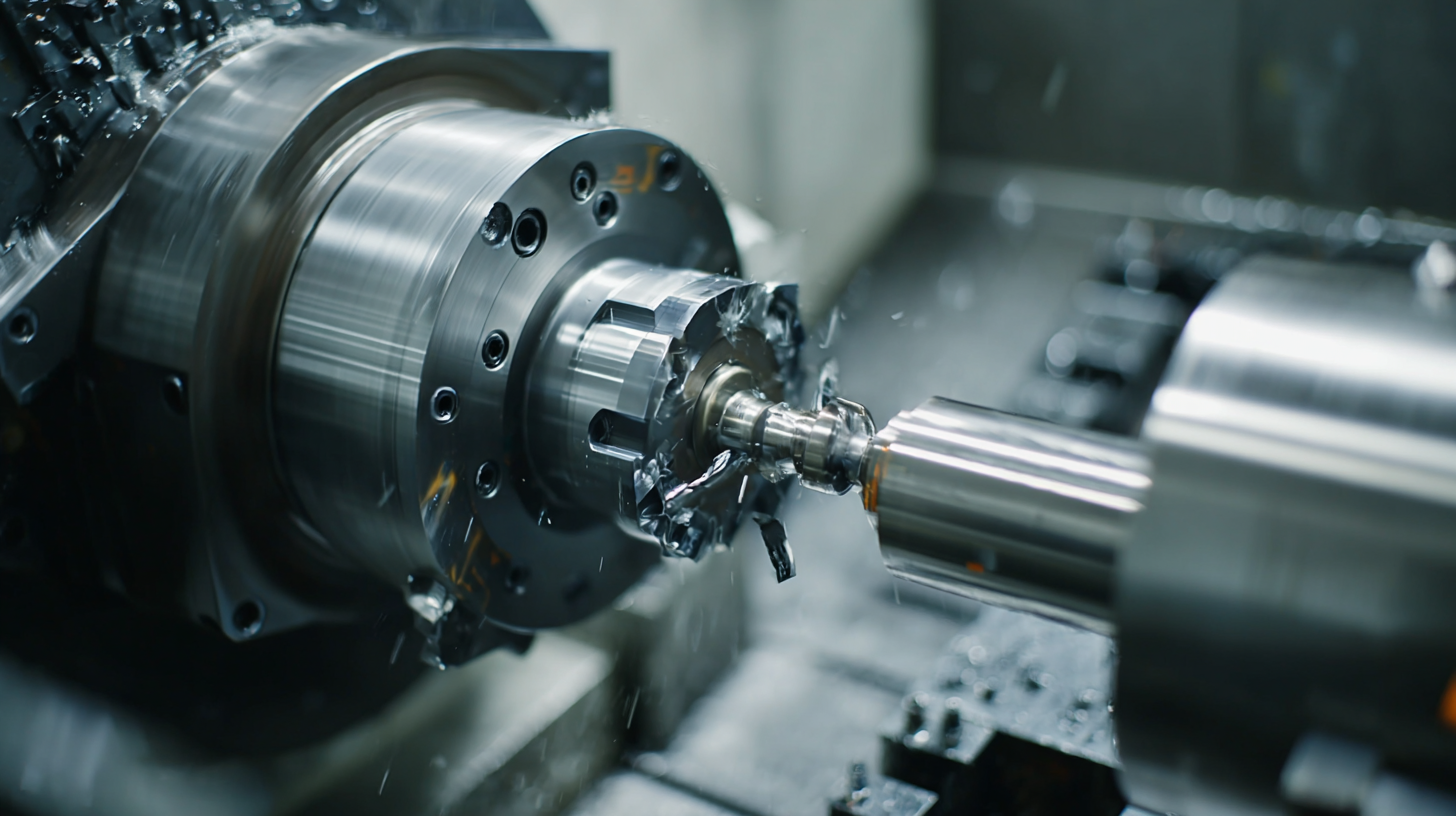

The landscape of manufacturing is continually evolving, with innovations in technology driving significant improvements in precision and efficiency. Among these advancements, the tool CNC machine has emerged as a cornerstone of modern manufacturing processes. Industry expert Dr. Emily Carter, a leading authority in CNC technology, states, "The latest innovations in tool CNC machines are not just enhancing productivity; they are redefining what is possible in precision engineering." This insight highlights the transformative potential of these machines in various manufacturing sectors.

As we delve into the top five innovations in tool CNC machines, it becomes evident that these advancements are not merely incremental; they represent a quantum leap forward in capabilities. From improved automation and artificial intelligence integration to enhanced materials and more precise tooling, manufacturers are witnessing a remarkable evolution. These innovations pave the way for heightened accuracy, reduced waste, and streamlined operations, making them indispensable for companies aiming to stay competitive in a fast-paced market.

In this article, we will unpack these groundbreaking developments and explore how they are unlocking new levels of precision in manufacturing. Understanding the role of tool CNC machines in this evolution will provide valuable insights for manufacturers looking to leverage cutting-edge technology for superior outcomes.

Advancements in CNC Machine Technology for Precision Manufacturing

The precision manufacturing sector is experiencing a remarkable transformation, driven by advancements in CNC (Computer Numerical Control) machine technology. Reports from the International Federation of Robotics indicate that CNC machines account for over 30% of total industrial robot installations, underscoring their crucial role in enhancing manufacturing accuracy. With features such as advanced motion control and high-speed machining capabilities, today's CNC machines can achieve tolerances of up to ±0.005 mm, enabling manufacturers to produce intricate components with unparalleled precision.

One significant innovation is the integration of AI and machine learning algorithms into CNC machines, allowing for real-time monitoring and adaptive machining processes. According to a study by Markets and Markets, the global CNC machine market is projected to reach $100 billion by 2026, highlighting the increasing reliance on these technologies. To fully leverage these advancements, manufacturers should invest in staff training programs that emphasize the importance of understanding CNC programming and maintenance.

Tips: Regularly calibrating machines can prevent wear and tear, leading to more consistent production quality. Additionally, exploring modular tooling systems can significantly reduce setup times and enhance flexibility for varied production runs.

The Impact of High-Speed Machining on Production Efficiency

High-speed machining (HSM) is revolutionizing the manufacturing sector by significantly enhancing production efficiency. This innovative approach utilizes advanced CNC machine technologies that operate at elevated speeds, allowing manufacturers to process materials more rapidly and with greater accuracy. As components are machined at faster rates, downtime is minimized, and throughput is maximized, leading to higher overall productivity. The ability to perform complex cuts and intricate designs without sacrificing quality makes HSM a game-changer for industries requiring precision and speed.

The benefits of high-speed machining extend beyond mere time savings. It allows for tighter tolerances and improved surface finishes, which are critical in sectors such as aerospace, automotive, and medical device manufacturing. With CNC machines capable of operating at high RPMs, firms can reduce cycle times, lower labor costs, and maintain a competitive edge in an increasingly global market. Moreover, the integration of sophisticated software into these machines streamlines the production process, facilitating real-time monitoring and adjustments, further boosting efficiency and product quality in today's fast-paced manufacturing landscape.

Integrating AI and Automation in CNC Operations

In modern manufacturing, the integration of artificial intelligence (AI) and automation in CNC operations is revolutionizing production processes. According to a report by McKinsey, AI can enhance productivity in manufacturing by up to 20%, significantly reducing the time and cost of machining. This integration enables CNC machines to analyze data in real-time, optimizing production schedules and minimizing downtime. AI-powered CNC systems can predict maintenance needs before equipment failures occur, thus saving manufacturers costly repairs and lost production time.

To fully leverage the benefits of AI and automation in CNC operations, manufacturers can adopt a few key strategies. First, invest in training programs to ensure that staff are equipped with the necessary skills to operate and manage these advanced systems effectively. Second, consider implementing a phased approach to automation that allows for gradual integration, minimizing disruption while maximizing learning opportunities. Finally, regular data analysis can lead to continuous improvement of operational efficiencies, significantly impacting overall output.

By embracing these innovations, companies not only enhance their production precision but also maintain a competitive edge in an increasingly demanding market. As the industry evolves, staying informed about advancements in technology will be crucial for long-term success.

Innovative Materials and Coatings: Enhancing Tool Performance

Innovative materials and coatings are key to enhancing the performance of CNC machines, empowering manufacturers to achieve unprecedented levels of precision and efficiency. Recent advancements in material science have led to the development of cutting tools made from high-strength alloys and advanced ceramics, which offer superior durability and wear resistance. These materials not only prolong the lifespan of the tools but also enable them to withstand extreme cutting conditions, resulting in smoother machining processes and reduced downtime.

Additionally, the application of high-performance coatings, such as titanium nitride (TiN) and diamond-like carbon (DLC), significantly boosts tool performance. These coatings provide a slick surface that minimizes friction, leading to enhanced cutting speeds and improved surface finish on machined components. By effectively reducing thermal buildup, these innovative coatings also help to prevent tool deformation and operate at higher temperatures, further optimizing the manufacturing process. As such, the integration of advanced materials and coatings in CNC machining presents a transformative opportunity for manufacturers aiming to elevate their production capabilities and meet the demands of modern industry.

Case Studies: Successful Implementation of Latest CNC Innovations

In the realm of advanced manufacturing, CNC (Computer Numerical Control) machines are at the forefront of revolutionizing production processes. Recent case studies highlight the successful implementation of the latest CNC innovations across various industries, showcasing how these advanced tools enhance precision and efficiency. For instance, manufacturers adopting state-of-the-art CNC technology have reported significant reductions in production time and increased accuracy in component fabrication, which leads to reduced waste and improved overall product quality.

China, emerging as a leader in advanced industries, is a key player in these innovations. With universities and domestic companies enhancing their innovation capabilities, the integration of intelligent robotics within CNC operations is becoming increasingly prevalent. As evidenced by recent developments, the synergy between CNC machines and intelligent robotics not only boosts manufacturing efficiency but also opens new avenues for automation in sectors like geriatric rehabilitation. Such advancements demonstrate the transformative potential of combining cutting-edge CNC technologies with smart robotics, paving the way for more effective and precise manufacturing solutions.

Related Posts

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.