Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

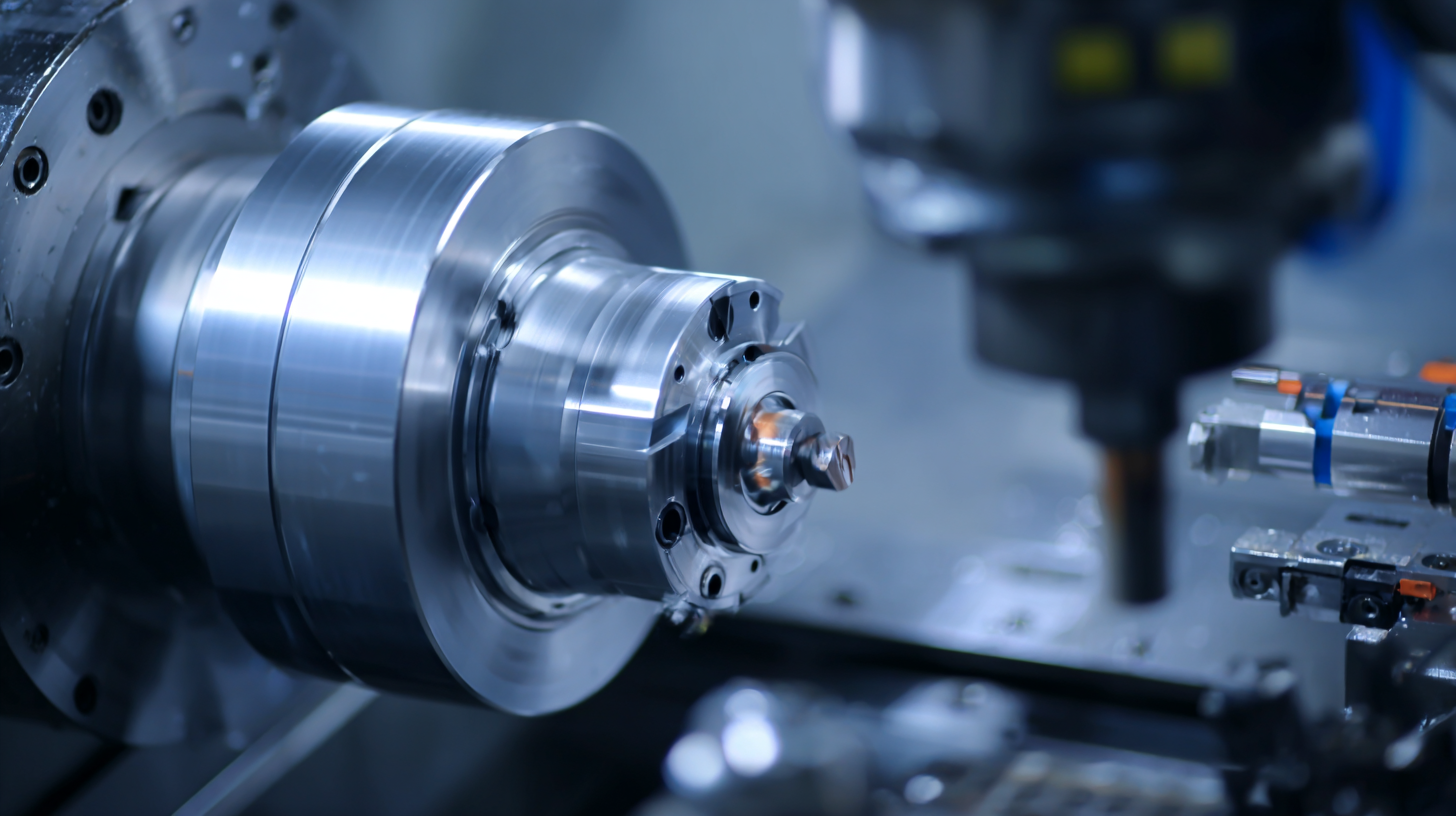

The rapid advancement of technology has ushered in a new era in various industries, significantly influenced by the rise of CNC machining and manufacturing. This revolutionary process leverages computer numerical control to enhance precision and efficiency in production, transforming traditional manufacturing landscapes. With the ability to create complex components with unrivaled accuracy, CNC machining and manufacturing have redefined standards across sectors such as aerospace, automotive, and healthcare. As businesses strive to meet the demands of modern consumers, the integration of these technologies not only streamlines operations but also fosters innovation, enabling the development of cutting-edge products. This evolving landscape highlights the crucial role that CNC machining and manufacturing play in shaping the future of industry, emphasizing the need for continuous adaptation and exploration of emerging technological possibilities.

The Evolution of CNC Machining: A Leap Towards Precision and Efficiency

The evolution of CNC machining has marked a significant leap towards enhanced precision and efficiency in manufacturing processes. As industries increasingly adopt CNC technology, the global CNC machine market is expected to surge, with projections estimating it will grow from $101.22 billion in 2025 to $195.59 billion by 2032. This growth highlights the importance of CNC advancements, which enable manufacturers to achieve higher levels of accuracy and speed, thereby transforming production capabilities across various sectors.

In addition to traditional machining benefits, the integration of smart automation and AI-driven solutions is revolutionizing the landscape of industrial fabrication. The emergence of sophisticated CNC systems allows for multi-axis machining, which is instrumental in producing complex geometries with minimal human intervention. As the demand for precision manufacturing escalates, the milling machine market alone is projected to reach approximately $116.7 billion by 2035, underlining the transformative power of new technologies in driving economic growth and sustainability within the manufacturing industry.

Transforming Traditional Industries: The Role of CNC in Modern Manufacturing

Computer Numerical Control (CNC) machining has rapidly transformed traditional industries, enhancing efficiency and precision in manufacturing processes. According to a report by Research and Markets, the global CNC machine market is projected to grow from $71 billion in 2022 to $99 billion by 2026, reflecting a CAGR of 8.2%. This growth underscores the increasing adoption of CNC technology across various sectors, such as aerospace, automotive, and metalworking, where the need for high precision and reduced production times is paramount.

CNC technology plays a pivotal role in modern manufacturing by automating processes that were once labor-intensive and prone to human error. Traditional methods often involved manual operations, which not only slowed production but also increased waste and inconsistencies. With CNC, manufacturers can achieve high levels of automation, leading to a reduction in production time by up to 50%, according to a study by the National Institute of Standards and Technology (NIST). This efficiency not only reduces costs but also allows for the production of complex geometries that were previously impossible, thereby enabling innovation in product design and functionality across many industries.

Enhancing Product Quality: The Benefits of CNC Technology in Production

CNC (Computer Numerical Control) technology has become a game changer in the manufacturing landscape, particularly in enhancing product quality across various sectors. The precision and automation offered by CNC machining allow manufacturers to produce components with remarkable accuracy and consistency, which significantly reduces waste and variation in the production process. Industries, such as rubber roller manufacturing, have observed substantial improvements in performance and efficiency, demonstrating how CNC machining not only enhances product quality but also drives overall operational efficiency.

Tips: To maximize the benefits of CNC technology, manufacturers should consider investing in regular training for their staff. Skilled operators can leverage advanced functionalities of CNC machines, ensuring optimal operation and minimizing errors. Additionally, integrating digital manufacturing technologies can provide real-time insights, further improving product quality and accelerating production timelines.

Moreover, as the CNC machine market continues to expand, with an expected CAGR of 5.5%, companies embracing these technologies are positioned to gain a competitive edge. By focusing on automation and smart manufacturing practices, businesses can enhance their productivity, adapt to market demands, and ultimately deliver higher-quality products to their customers.

Cost Reduction Strategies: How CNC Machining Affects Industry Economics

CNC machining has emerged as a pivotal technology in modern manufacturing, significantly influencing industry economics through various cost reduction strategies. By automating intricate processes and minimizing human error, CNC machining enhances precision and efficiency, leading to reduced material waste and cycle times. This not only lowers production costs but also allows manufacturers to offer competitive pricing, which is crucial in today’s fast-paced market environment.

Moreover, the adoption of CNC machining supports the implementation of a circular economy within manufacturing systems. By optimizing designs and using multi-method simulations, businesses can link their operational strategies with sustainability goals. This approach enables manufacturers to serve more customers effectively while also mitigating lifecycle costs through improved resource management. Ultimately, the integration of CNC machining into manufacturing processes is revolutionizing industry practices, fostering a more economically and environmentally sustainable landscape.

Future Trends: The Next Frontiers of CNC Technology in Various Sectors

The future of CNC technology is poised to transform various sectors, driving innovation and efficiency in manufacturing processes. As industries increasingly adopt automation and robotics, CNC machining is set to evolve, integrating advanced features like artificial intelligence and machine learning. These advancements will enable smarter production systems that can learn from operational data, optimize workflows, and reduce waste. Consequently, companies can expect substantial cost savings while maintaining high-quality output.

In addition to automation, sustainability is becoming a key focus for the next generation of CNC technology. The industry is turning towards eco-friendly materials and energy-efficient practices to minimize environmental impact. With the rise of additive manufacturing techniques, CNC machining will increasingly complement 3D printing, allowing for more complex designs and reduced material consumption. Sectors such as aerospace, automotive, and healthcare are already exploring these pathways, paving the way for a more sustainable and innovative future in manufacturing.

Future Trends in CNC Machining and Manufacturing

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.