Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

In the rapidly evolving landscape of manufacturing, the integration of advanced CNC machining equipment has emerged as a transformative force, redefining efficiency and precision. According to a recent report by MarketsandMarkets, the CNC machine market is expected to reach $100 billion by 2025, driven by the increasing demand for automation and high-quality production processes across various sectors. This surge highlights the critical role of CNC machining equipment in enhancing operational workflows and reducing lead times. Industries such as aerospace and automotive have begun leveraging these innovations, achieving remarkable improvements in productivity and product quality. As manufacturers seek to stay competitive in an increasingly digital economy, embracing cutting-edge CNC machining equipment becomes not just advantageous, but essential. This article will explore effective strategies for optimizing manufacturing processes through the implementation of advanced CNC machining solutions, offering insights into best practices that can lead to significant operational advancements.

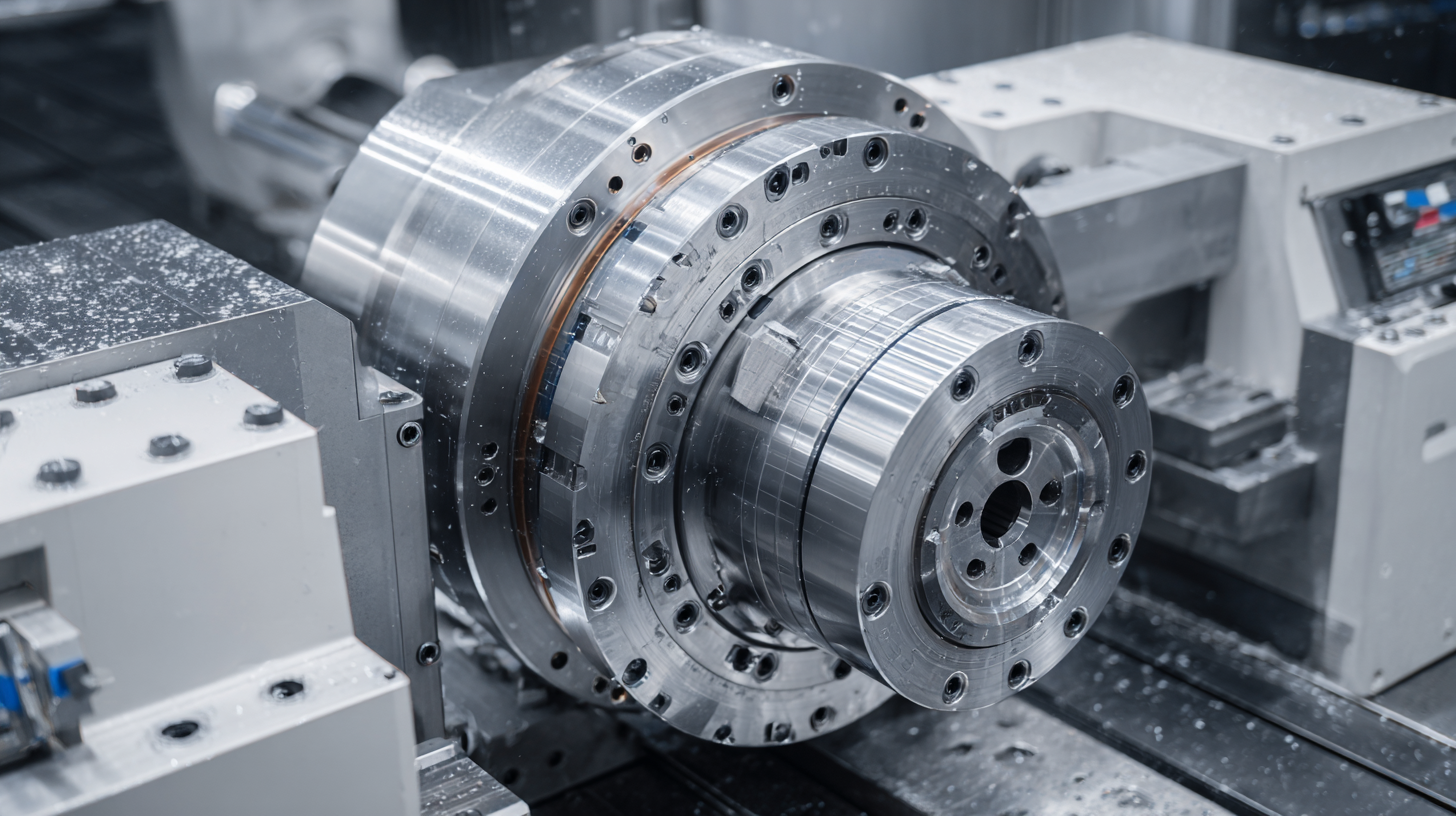

Exploring the Benefits of Advanced CNC Machining in Modern Manufacturing

Advanced CNC machining has emerged as a game-changer in modern manufacturing, streamlining processes and enhancing precision. This technology allows manufacturers to produce complex parts with remarkable accuracy and repeatability, significantly reducing production times. With the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, CNC machines can interpret intricate designs and execute them flawlessly, minimizing human error. This level of precision is vital for industries such as aerospace and automotive, where component reliability and performance are paramount.

Moreover, advanced CNC machining equipment solutions offer increased flexibility in production. Manufacturers can quickly switch between different product designs without extensive reconfiguration, allowing for quicker responses to market demands. This adaptability not only optimizes production lines but also enables the production of low-run, high-complexity parts that were previously cost-prohibitive. As companies embrace these technologies, they are not only improving their operational efficiency but are also paving the way for innovation and competitive advantage in a fast-evolving manufacturing landscape.

Integrating Automation and CNC Technology for Enhanced Production Efficiency

The integration of automation and CNC (Computer Numerical Control) technology is leading a transformative wave in manufacturing processes across various industries. By employing advanced CNC machining equipped with AI-driven generative design, companies can significantly enhance production efficiency. This convergence of intelligent design and automation not only streamlines operations but also reduces material waste, ensuring that manufacturers can respond more flexibly to market demands.

As projected, the generative CNC market is expected to expand substantially between 2025 and 2035, driven by the growing adoption of these advanced technologies. Industries such as automotive manufacturing, projected to be worth $41.70 billion by 2030, are increasingly investing in CNC solutions that incorporate automation to achieve higher productivity levels. Additionally, the woodworking machinery market is also set to grow, reflecting a broader trend where sophisticated CNC systems are redefining traditional manufacturing paradigms. The emphasis on rapid tool changes and efficient material handling symbolizes a pivotal shift towards smarter, more responsive production environments.

Key Considerations When Selecting CNC Machining Equipment for Your Facility

When selecting CNC machining equipment for your facility, several key considerations can significantly impact your manufacturing processes. First, assess the specific needs of your production. Consider the materials you will be working with and the types of parts you intend to produce. Different CNC machines cater to unique requirements; for instance, vertical machining centers are often best for intricate designs, while horizontal mills can handle larger workpieces efficiently.

Tips: Always consider the machine's versatility. Machines that can handle a range of materials and machining techniques can save time and costs in the long run. Additionally, factor in the level of automation you desire; higher automation can lead to reduced labor costs and increased productivity.

Another crucial aspect is the machine's precision and reliability. Look for CNC equipment with high accuracy specifications to ensure the best quality of the finished products. It's also advisable to evaluate the machine's operational ease—user-friendly interfaces can minimize training times and decrease the likelihood of errors on the shop floor.

Tips: Don't overlook the support and maintenance services provided by the manufacturer. A good support system can make a significant difference in maximizing uptime and maintaining efficiency in your operations.

Best Practices for Maintaining CNC Machines to Maximize Longevity and Performance

CNC machining equipment plays a pivotal role in modern manufacturing processes, but maintaining these machines to ensure optimal performance and longevity is crucial. Regular maintenance not only minimizes downtime but also enhances the precision and efficiency of manufacturing operations. Implementing a proactive maintenance schedule can significantly extend the life of CNC machines.

Tips: One effective tip is to establish a routine inspection checklist. This should include checking fluid levels, inspecting belts and ballscrews, and ensuring that all electrical connections are secure. Additionally, cleaning the machine regularly helps to prevent the buildup of debris and coolant residue, which can hinder performance over time.

Another important practice is to train operators on the correct usage and handling of CNC equipment. Proper training ensures that operators understand how to avoid common mistakes that can lead to wear and tear. Encouraging operators to report any unusual sounds or irregularities can also facilitate early detection of potential issues, allowing for timely interventions that can save costs and extend machine life.

Trends in CNC Machining: How Digital Transformation is Shaping the Industry

The CNC machining industry is undergoing a significant transformation driven by digital technologies that enhance precision engineering, thereby facilitating market growth.

By integrating advanced software solutions and high-quality computer numerical control machines, manufacturers can achieve remarkable accuracy in woodworking applications. This shift not only improves the quality of wooden products but also streamlines production processes, leading to increased efficiency and reduced waste.

One emerging trend is the adoption of hybrid solutions that combine traditional woodworking techniques with cutting-edge CNC technology. This approach allows manufacturers to produce customized designs with tight tolerances, ultimately capturing a larger market share in the woodworking machinery sector.

The ability to meet consumer demands for quality and personalization, coupled with the benefits of automation, positions CNC machining as a vital player in the revolutionizing landscape of manufacturing processes. As companies embrace these innovations, they pave the way for significant advancements in product offerings and operational capabilities.

Related Posts

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

The Future of Precision Machining Innovations Transforming Industry Standards

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.