Top 10 CNC Machine Tools Every Engineer Should Know in 2023

In the ever-evolving landscape of manufacturing, the importance of precision engineering cannot be overstated. As of 2023, the global CNC machine tools market is projected to reach USD 100 billion, reflecting a compound annual growth rate (CAGR) of approximately 7.5% from 2020 to 2026, according to industry reports. This growth underscores the significance of adopting advanced technology in tool CNC machines to enhance productivity and efficiency. Engineers across various sectors are increasingly relying on CNC machines to execute complex designs with unrivaled accuracy, thereby meeting the rising demand for high-quality manufactured components.

A comprehensive understanding of the top CNC machine tools is essential for engineers looking to remain competitive in this dynamic market. Today’s CNC tools not only automate production processes but also integrate with smart technologies to improve operational insight and resource management. Reports suggest that the adoption of CNC machines can lead to a significant reduction in production costs – by as much as 30% – while also increasing output rates, making them indispensable in modern manufacturing settings. As we explore the top 10 CNC machine tools every engineer should know in 2023, we highlight their roles in shaping the future of manufacturing and the critical skills needed to leverage these powerful tools effectively.

Key Features of CNC Machine Tools in 2023

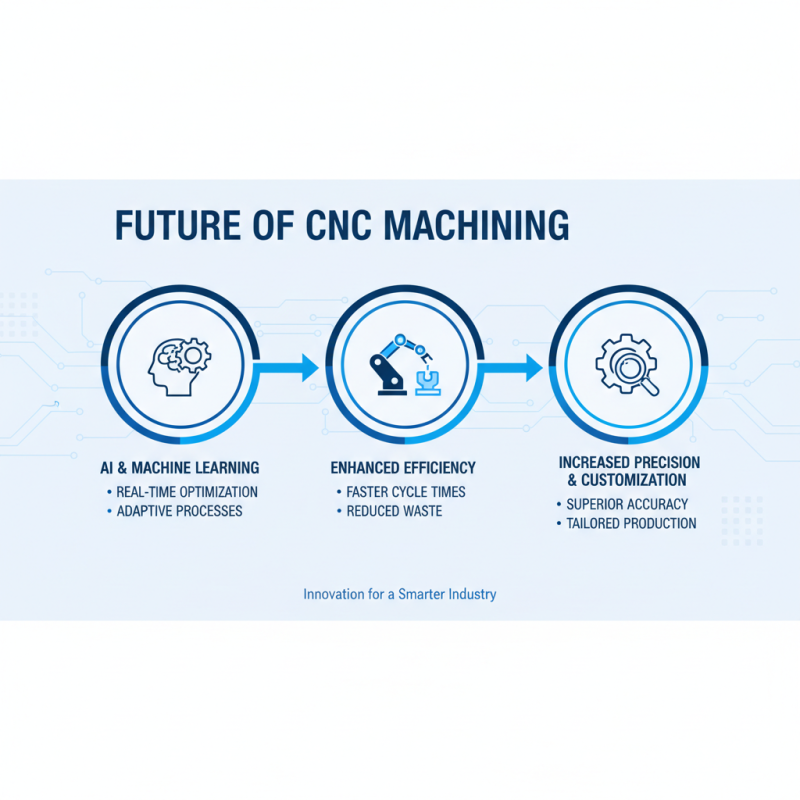

In 2023, CNC machine tools are more advanced than ever, with several key features that are essential for engineers to understand. One significant development is the integration of artificial intelligence (AI) and machine learning. These technologies enable CNC machines to learn from previous operations, optimizing processes and reducing waste. Real-time data analysis helps in predictive maintenance, minimizing downtimes and increasing overall efficiency. This evolution in smart manufacturing allows engineers to enhance productivity levels while maintaining high precision and quality in their output.

Another notable feature is the increased versatility of CNC machines. The modern tools are now capable of handling a broader range of materials, including composites and advanced alloys. Multi-function CNC machines that can perform milling, turning, and even 3D printing in one setup are gaining popularity. This versatility simplifies the manufacturing process, saves space, and reduces production time, making it easier for engineers to adapt to the changing demands of various industries. Additionally, advancements in user interfaces, such as touchscreens and intuitive software, allow for easier operation and programming, making these tools accessible even to those with less experience.

Top 10 CNC Machine Tools Every Engineer Should Know in 2023 - Key Features of CNC Machine Tools in 2023

| Machine Tool | Key Feature | Application | Material Compatibility |

|---|---|---|---|

| CNC Lathe | High precision rotation | Turning operations | Metal, Plastics |

| CNC Milling Machine | 3D contouring capabilities | Milling and drilling | Metal, Wood, Composites |

| CNC Router | Versatile cutting and shaping | Sign making, cabinetry | Wood, Plastics, Soft Metals |

| Laser Cutter | High speed cutting | Precision cuts in various materials | Metal, Wood, Acrylic |

| Wire EDM | Fine detail cutting | Complex shapes and thin materials | Steel, Carbide |

| Plasma Cutter | Extreme heat cutting | Cutting thick steel | Steel, Aluminum |

| CNC Vertical Machining Center | Multi-axis operations | Complex machining | Metal, Plastic |

| CNC Horizontal Machining Center | Efficient chip removal | High-volume production | Metal |

| 5-Axis CNC Machine | Advanced multi-axis machining | Complex geometries | Metals, Composites |

| CNC Machine Simulation Software | Real-time simulation | Process verification and optimization | N/A |

Types of CNC Machines: A Comprehensive Overview

CNC machines, or Computer Numerical Control machines, have revolutionized the manufacturing landscape, providing precision and efficiency across various industries. Understanding the types of CNC machines is crucial for engineers and designers working to meet modern production demands. The most common types include CNC milling machines, CNC lathes, CNC routers, and CNC plasma cutters. Each machine serves distinct purposes, tailored to specific materials and project requirements, allowing for a broad range of applications from intricate designs to large-scale production.

CNC milling machines are versatile tools capable of performing various operations, including drilling, cutting, and shaping materials like metal, wood, and plastic. They operate with multiple axes, often featuring vertical and horizontal configurations. On the other hand, CNC lathes focus primarily on rotating the workpiece against a stationary cutting tool, making them ideal for producing cylindrical parts with a high degree of accuracy. Meanwhile, CNC routers are predominantly used for woodworking and plastic fabrication, allowing for detailed work on sheet materials. Finally, CNC plasma cutters utilize high-heat plasma to cut through electrically conductive materials, making them suitable for metalworking and industrial applications. Each type contributes uniquely to the efficiency, precision, and versatility of modern manufacturing processes.

Top 10 CNC Machine Tools in 2023

This chart illustrates the popularity of different types of CNC machines based on industry usage in 2023. The data shows the percentage of engineers who use each type of CNC machine tools.

Applications of CNC Machine Tools Across Various Industries

CNC machine tools have transformed manufacturing across various industries, enhancing precision, efficiency, and productivity. In 2023, the applications of CNC technology span sectors from aerospace to automotive engineering, with data showing that the global CNC machine market is projected to reach over $100 billion by the end of the year. This steady growth reflects the increasing demand for automation and sophisticated machining capabilities that CNC tools provide.

In the aerospace industry, for instance, CNC machines play a critical role in producing complex components that meet stringent safety and performance standards. According to a recent report by Industry Research, the aerospace segment is expected to witness a CAGR of 5% through 2026, driven largely by advancements in CNC machining technologies. Similarly, in the automotive sector, CNC tools are utilized for manufacturing intricate parts and assemblies, contributing to improved vehicle performance and reliability. With the industry's ongoing shift towards electric vehicles, the demand for precise machining is more significant than ever.

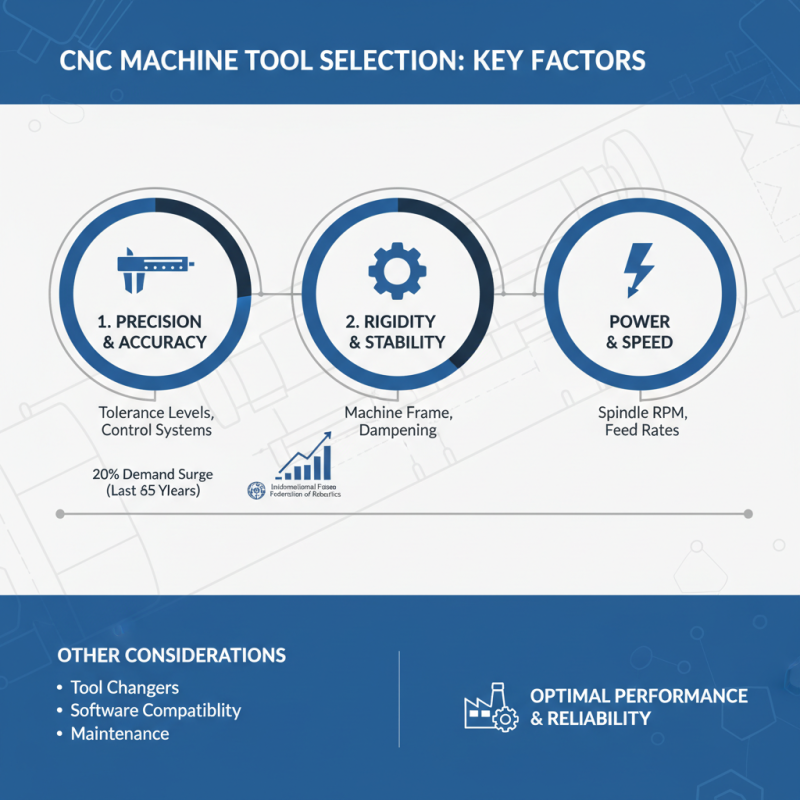

Factors to Consider When Choosing CNC Machine Tools

When selecting CNC machine tools, engineers should consider several critical factors to ensure optimal performance and reliability. One of the primary considerations is the machine's precision and accuracy. According to a report by the International Federation of Robotics, the demand for high-precision CNC machines has surged by over 20% in the past three years, indicating a significant shift towards automation that requires exacting standards. Engineers must evaluate the machine's tolerance levels and the capabilities of its control systems to meet specific manufacturing needs.

Another essential factor is the versatility of the CNC machine. With industries increasingly seeking multi-functional equipment that can adapt to various tasks, the ability to handle different materials and techniques can significantly influence decision-making. Data from a recent AMT report suggests that multifunctional CNC machines could reduce production costs by up to 30%, making them a more attractive investment. Engineers should assess whether a machine can accommodate different tool setups and whether it supports advanced programming languages, which can enhance flexibility in production processes.

Future Trends in CNC Machining Technology and Innovation

As the manufacturing industry continues to evolve, the future of CNC machining technology is marked by significant innovations aimed at enhancing efficiency and precision. One of the most notable trends is the integration of artificial intelligence (AI) and machine learning into CNC processes. These technologies enable machines to learn from previous operations, optimizing parameters in real-time to improve cycle times and reduce waste. This level of adaptability not only enhances productivity but also allows for a higher degree of customization in production runs.

Additionally, the rise of Industry 4.0 is driving the development of smart factories where CNC machine tools are interconnected through the Internet of Things (IoT). This connectivity facilitates seamless data exchange between machines, leading to advanced predictive maintenance capabilities. By monitoring the condition of machines in real-time, engineers can anticipate potential failures before they occur, minimizing downtime and extending the lifespan of equipment. Furthermore, advancements in additive manufacturing technologies are blurring the lines between traditional CNC machining and 3D printing, offering new avenues for design flexibility and material efficiency in various applications.

Related Posts

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

2025 How to Achieve High CNC Machining Precision in Manufacturing

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.