Top One Off CNC Machining Techniques to Know in 2026

In the rapidly evolving landscape of manufacturing, one off CNC machining stands out as a pivotal technique for customized projects. Industry expert Dr. Emily Chen, a leading figure in precision engineering, emphasizes the importance of versatility in this field. She states, “One off CNC machining allows for unique designs that traditional methods can’t achieve.” This flexibility makes it invaluable for prototypes and bespoke items.

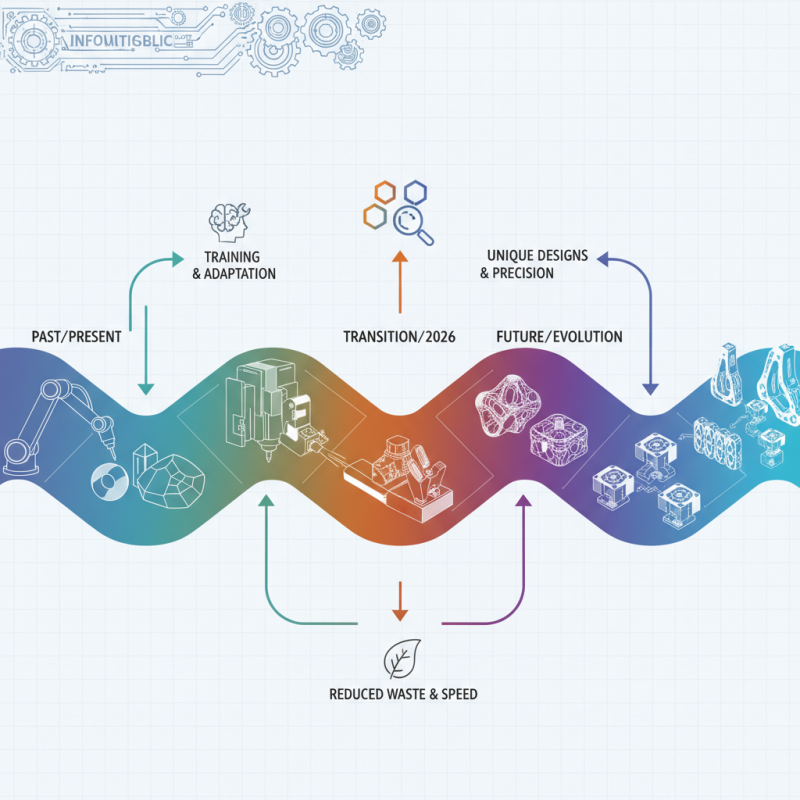

As we approach 2026, the focus on one off CNC machining is shifting. Companies are seeking more efficient methods to reduce waste and speed up production. Innovative techniques emerge, enabling manufacturers to meet precise specifications. Yet, not every approach proves effective. Some fail to accommodate complex geometries or intricate details. The challenge lies in balancing creativity with functionality.

Embracing these advanced techniques can be daunting. Companies must invest time and resources to train personnel and adapt equipment. Nonetheless, the potential rewards are significant. As businesses explore one off CNC machining, they must reflect on their processes and remain open to learning. The industry's future depends on this continual evolution and exploration.

Key CNC Machining Techniques Dominating the Industry in 2026

In 2026, several CNC machining techniques will dominate the industry. High-speed machining will continue to gain traction. This technique boasts enhanced efficiency and precision, making it a top choice for complex parts. However, mastering this technique requires attention to tool selection and programming.

Another key technique is multi-axis machining. This approach allows for intricate designs and reduces production time. Many shops still struggle with this technology. Mistakes in part setups can lead to wasted materials. Investing in training is essential to mitigate these risks.

Tips: Always review your machine setups before starting. Verify tool paths and integrate real-time monitoring systems. These steps can prevent costly errors. Adapting to these techniques may feel overwhelming. Embrace the learning curve, and make continuous improvements a vital part of your strategy.

Understanding the Principles of One Off CNC Machining

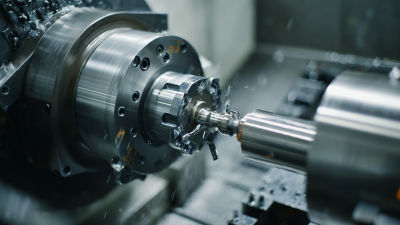

One-off CNC machining is about precision. Each piece is unique, tailored to specific needs.

This technique allows for creative freedom. Designers can experiment without the constraints of mass production.

The machine processes the material precisely as designed, creating complex shapes and intricate details.

Every cut has purpose and intention.

Understanding the principles behind this machining technique is essential. It relies on computer-aided design and

advanced software. Operators must have a clear vision of the final product. Mistakes can be costly.

Even a minor error in programming can lead to wasted materials. This aspect encourages constant learning and improvement.

One-off runs challenge machinists. They must think on their feet and adapt to changes.

Each project can reveal different skills needed. This unpredictability makes the process both exciting and nerve-wracking. There is always room for

refinement. Future advancements will likely introduce new challenges and techniques.

The journey is as crucial as the destination.

Innovative Materials for One Off CNC Machining in 2026

The landscape of one-off CNC machining is rapidly evolving, particularly in the materials used. In 2026, innovations in materials will define machining capabilities. Advanced composites are coming into the spotlight. These materials offer lightweight options that can withstand high stress levels. For instance, carbon fiber composites can reduce weight by up to 60%, making them ideal for aerospace applications.

Metal alloys also continue to see enhancements. The integration of titanium and aluminum alloys, for example, can lead to parts that are both strong and corrosion-resistant. Reports indicate that these alloys can improve performance by 30% in certain conditions. However, sourcing these materials poses challenges. Not all suppliers meet the quality standards necessary for precision machining. This inconsistency can lead to production delays and safety concerns.

Sustainability is becoming an important factor too. Biodegradable polymers are emerging as alternatives. They promise a lower environmental impact. Yet, the trade-off often involves durability and machining efficiency. Balancing these aspects is crucial for innovation. The adoption of new materials still requires thorough testing. Without proper validation, risks may outweigh the benefits. The road ahead will require careful navigation through these complexities.

Top One Off CNC Machining Techniques to Know in 2026 - Innovative Materials for One Off CNC Machining in 2026

| Technique | Material | Applications | Advantages |

|---|---|---|---|

| 5-Axis Machining | Titanium Alloys | Aerospace Components | High precision and complexity |

| Laser Cutting | Carbon Fiber | Automotive Parts | Minimal material waste and intricate designs |

| EDM (Electrical Discharge Machining) | Hardened Steel | Mold Making | Ability to machine hard materials with high accuracy |

| CNC Milling | Aluminum Alloys | Consumer Electronics | High speed and efficient production |

| Additive Manufacturing | Nylon | Prototyping | Complex shapes and efficient material use |

Emerging Technologies Enhancing CNC Machining Efficiency

As we look ahead to 2026, CNC machining is set to evolve with emerging technologies. Understanding these advancements is crucial for enhancing efficiency.

3D printing is revolutionizing this field. It allows rapid prototyping and reduces material waste. However, it also demands adaptations from traditional machining practices.

Another promising technology is AI-driven automation. It enables real-time monitoring and optimization of machining processes. Such innovations can increase precision and decrease downtime. Yet, integrating AI can pose challenges. Workers may face a learning curve and resistance to new methods.

When considering these technologies, it's important to stay informed. Here are some tips:

1. Invest in training for your team to make the transition smoother.

2. Test new tools on smaller projects before full-scale implementation.

3. Gather feedback from the team, addressing any concerns they might have.

The future of CNC machining holds great promise. However, it also requires flexibility and willingness to adapt. Embracing technology is essential, but so is reflecting on its impact on your processes.

Best Practices for Achieving Precision in CNC Machining Projects

Achieving precision in CNC machining projects can be challenging. It often requires careful planning and execution. One key practice is thorough design review. Examine each detail of your CAD model. Engaging all stakeholders early can help identify potential issues before machining begins.

Tool selection also plays a crucial role. The right tool can improve accuracy and reduce wear. Don’t overlook the importance of regular maintenance too. A worn tool can lead to unexpected errors. In an ideal world, all tools should be in perfect condition. Yet, that’s not always feasible.

Lastly, machining environment matters. Dust and temperature fluctuations can affect outcomes. An ideal space is climate-controlled and clean. However, not every workshop meets these standards. Strive for improvement, but acknowledge limitations in your current setup. Embrace feedback to refine your processes continually. Every project is a learning opportunity.

Related Posts

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

-

Unlocking Precision in Manufacturing with the Latest Tool CNC Machine Innovations

-

10 Essential CNC Machining Tips to Boost Efficiency by 25% in 2023

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.