Top Machining and Manufacturing Techniques Explained?

Machining and manufacturing are vital processes in today’s industrial landscape. These techniques shape materials into usable products. They are critical in sectors like automotive, aerospace, and electronics. Understanding the different methods can enhance production efficiency and product quality.

Various machining and manufacturing approaches exist, each with unique benefits and challenges. For instance, CNC machining offers precision but may involve higher costs. On the other hand, 3D printing provides flexibility but can have limitations in material selection. These variations can lead to difficulties if not understood well.

Moreover, the rapid advancements in technology add complexity to these fields. Manufacturers must adapt or risk falling behind. Investing in training and equipment is essential, yet it’s often overlooked. Thus, evaluating the right technique is crucial for sustainable growth in the competitive marketplace.

Overview of Machining Techniques in Modern Manufacturing

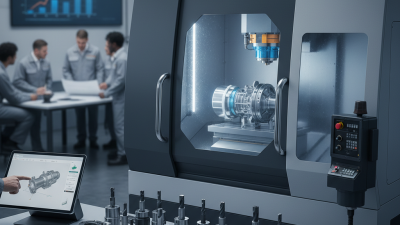

Machining techniques play a critical role in modern manufacturing. Precision is essential. A report from a manufacturing association states that nearly 30% of manufacturing costs are driven by inefficient machining. This highlights the need to optimize processes. Common methods include turning, milling, and grinding. Each has unique strengths and weaknesses, impacting overall productivity.

Turning is often used for cylindrical parts. It allows for high precision. However, it requires skilled operators. Data shows that about 50% of machining errors stem from operator inexperience. Milling, on the other hand, can produce complex shapes. It's versatile but often leads to longer production times. Grinding is great for achieving tough tolerances, yet it can be less cost-effective due to slower speeds.

Emerging technologies are reshaping these techniques. Automation helps reduce human error. However, it brings challenges too. The learning curve for operators can be steep. Industry reports indicate that companies need to invest in training. Only 45% of firms have adequately prepared their workforce for advanced machining processes. Traditional methods must adapt to stay competitive. Each technique has potential, but gaps in implementation remain.

Understanding Subtractive vs. Additive Manufacturing Processes

When discussing modern manufacturing, two main processes emerge: subtractive and additive manufacturing. Subtractive manufacturing involves removing material from a solid block. This technique, often used in machining, can create precise parts but may yield a lot of waste. Cutting, drilling, and milling are common methods. They require careful planning and skill. Mistakes can lead to wasted time and expensive materials.

On the other hand, additive manufacturing builds products layer by layer. This technique includes 3D printing. It offers greater design freedom and minimizes waste. However, it can be slower for large items. The surface finish might not be as smooth as with subtractive methods. This process requires a different mindset, focusing on bit-by-bit assembly rather than removal.

Both approaches have their complexities and limitations. Subtractive methods can achieve high precision, but often at the cost of material. Additive techniques allow for creative designs but may struggle with durability. Manufacturers need to reflect on their specific needs and project goals. Balancing efficiency and quality is a constant challenge.

Key Tools and Equipment Used in Machining

Machining relies on various tools and equipment to achieve precision. A lathe is fundamental in shaping metal. It rotates the workpiece against cutting tools. This process enables the creation of cylindrical parts. Knowledge about lathes is essential for any machinist.

Milling machines are equally important. They use rotating cutters to remove material. A skilled operator can create complex shapes. However, this requires practice and patience. Setups can be challenging, and inaccuracies happen. Learning from mistakes is crucial in mastering milling processes.

Additionally, drill presses allow for precise hole creation. They can vary in size from small to industrial level. While they seem straightforward, matching the right drill bit is essential. Wrong choices can lead to damaged materials. Each tool has its flaws and strengths, making knowledge vital for successful machining.

Top Manufacturing Techniques and Their Popularity

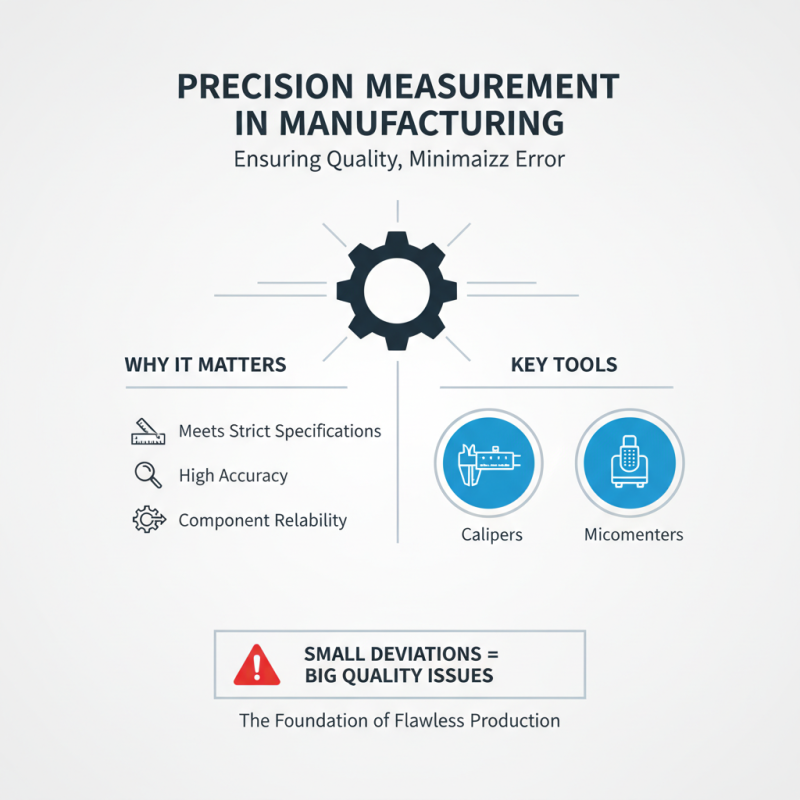

Precision Measurement and Quality Control in Fabrication

In machining and manufacturing, precision measurement is crucial. It ensures that every component meets strict specifications. With tools like calipers and micrometers, engineers can attain high accuracy. However, achieving this level of precision is not always straightforward. Measuring even the smallest deviation can lead to significant quality issues.

Quality control involves more than just measurement. It requires a systematic approach to identify and rectify defects. Regular inspections and audits can uncover underlying problems. Mistakes often arise from human error in measurement or misinterpretation of data. An operator may misread a dial or fail to calibrate a tool properly. These small oversights can lead to large-scale production failures.

In fabrication, continuous improvement is vital. Workers must engage in training to refine their skills. Investing in better tools may help, but they are not a magic solution. Errors can still occur, regardless of technology. Constant vigilance is needed to maintain quality. Reflecting on past mistakes is essential for future success. Quality control is an ongoing journey, not a destination.

Emerging Trends in Advanced Manufacturing Technologies

Emerging trends in advanced manufacturing technologies are transforming the industry. A report by Deloitte suggests that the global advanced manufacturing market is projected to reach $1.9 trillion by 2026. This growth is driven by the adoption of automation and artificial intelligence.

Additive manufacturing, or 3D printing, is one key area of development. It allows for the creation of complex designs with less material waste. According to a study by Wohlers Associates, the 3D printing industry experienced a 21% growth in 2021 alone. However, challenges remain in material limitations and scalability for larger production runs.

Digital twins are also gaining traction. They enable manufacturers to create virtual replicas of physical processes, improving efficiency. A report from McKinsey highlights that using digital twins can reduce development time by 50%. Yet, implementing these technologies requires significant investment and expertise, which can be a barrier for small to medium-sized enterprises seeking to adapt.

Related Posts

-

How to Improve Efficiency in Machining and Manufacturing Processes

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

How to Choose the Best Precision Machining and Manufacturing Services for Your Business Needs

-

Top 10 Advancements in Machining Technology You Need to Know About

-

10 Essential Tips for Choosing the Right Machine Tool in CNC

-

Top 10 Best Machine Tools for Precision Engineering in 2023

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.