“Top 10 Manual Machines for Precision Work: Essential Tools for Every Workshop”

In the world of precision engineering, the importance of manual machines cannot be overstated. As per the latest industry reports, demand for manual machinery remains strong, with an estimated market growth rate of 4.5% annually through 2025, due in part to their versatility and reliability in various applications, from metalworking to woodworking. Manual machines offer unique benefits that automated systems sometimes cannot replicate, such as fine control and the ability to perform complex tasks without the need for extensive programming.

The combination of craftsmanship and advanced technology elevates the role of manual machines in workshops across the globe. According to a 2022 survey by the Precision Engineering Industry Association, over 70% of professionals in the field noted that having access to high-quality manual machines significantly enhances their productivity and the precision of their work. With capabilities that range from milling and drilling to grinding and shaping, these essential tools empower artisans and technicians to achieve the exacting standards required in today's highly competitive manufacturing landscape. In this context, identifying the top manual machines for precision work becomes imperative for any workshop aspiring to excel in quality and efficiency.

Overview of Manual Machines in Precision Work

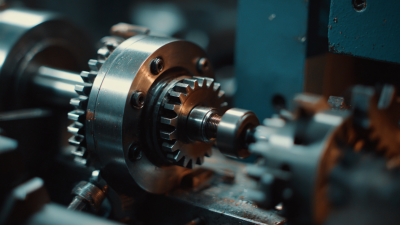

Manual machines play a crucial role in achieving precision in various workshops, catering to a plethora of industries, from metalworking to woodworking. A recent industry report highlights that the demand for manual machines in precision work has surged by approximately 15% over the last two years, driven by their reliability and the skilled craftsmanship they enable. Unlike automated counterparts, manual machines provide operators with the tactile feedback and control required to execute intricate tasks with high accuracy, making them indispensable for creating bespoke components where precision is paramount.

In the realm of manual machining, tools such as lathes, milling machines, and drill presses are frequently utilized. According to the National Tooling and Machining Association (NTMA), 70% of surveyed professionals reported that manual mills remain a favored choice for tasks requiring fine adjustments, underscoring their significance in maintaining tight tolerances. These machines are instrumental in prototyping and small-scale production runs, where flexibility and precision are not just beneficial but essential for success. By harnessing the capabilities of manual machines, workshops can maintain high levels of craftsmanship and precision, which automated systems may fall short of, particularly in custom applications.

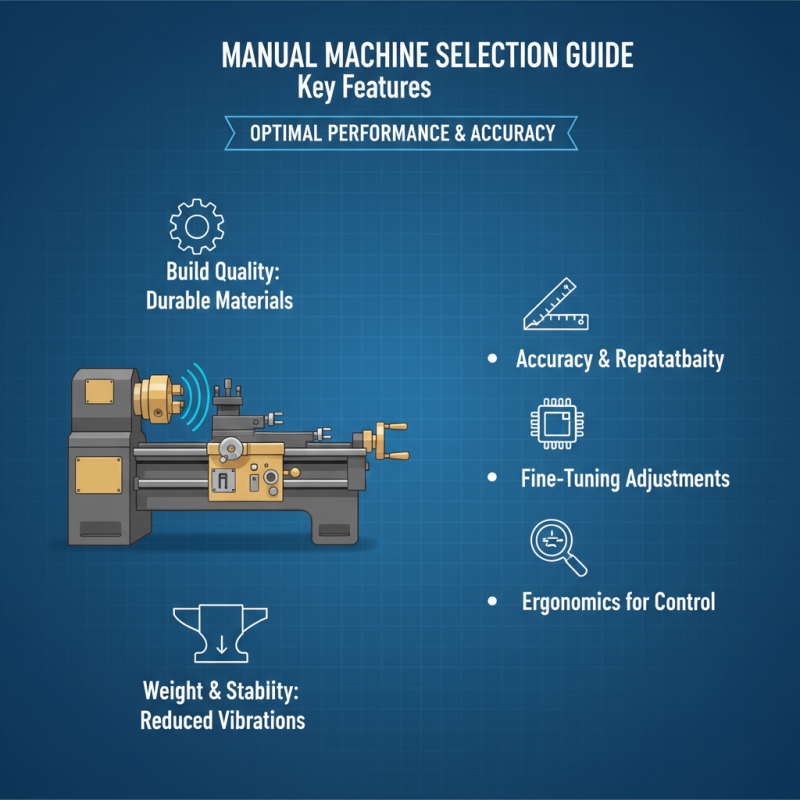

Key Features to Consider in Precision Tools

When selecting manual machines for precision work, several key features should be carefully considered to ensure optimal performance and accuracy. First and foremost, the machine's build quality plays a crucial role. Tools constructed from durable materials not only withstand the rigors of heavy use but also maintain their precision over time. Additionally, the weight and stability of the machine can greatly impact its usability; a heavier machine is often more stable, reducing the likelihood of vibrations that can compromise accuracy during operation.

Another vital aspect is the adjustability of the precision tool. Features such as fine-tuning knobs, dials, or digital displays allow for precise adjustments, catering to various project specifications. Furthermore, the design of the machine should enhance ergonomics, making it comfortable for the user to operate for extended periods. Easy accessibility to controls, a well-placed work surface, and an intuitive layout can significantly improve the user experience and efficiency, enabling craftsmen to focus on the task without unnecessary distractions. Overall, considering these features will help ensure that the selected tools deliver the precision and reliability necessary for high-quality workmanship.

Top 10 Manual Machines for Precision Workshop Applications

In the realm of precision workshop applications, selecting the right manual machines is vital for achieving optimal results in various projects. These machines, including lathes, milling machines, and band saws, provide meticulous control over intricate tasks. Manual operation allows users to develop a deep understanding of their craft, fostering skills that can be lost with automated tools. This hands-on approach not only enhances precision but also encourages creativity, making it essential for artisans and craftsmen across numerous industries.

The versatility of manual machines adds to their appeal, as they can be adapted for different materials and specific project requirements. For instance, a bench drill can be fine-tuned for both drilling delicate holes in wood and more robust operations on metal components. Furthermore, the simplicity of these machines often means lower maintenance costs and ease of repair, which are crucial aspects for workshops that value efficiency and reliability. Overall, incorporating manual machines into a workshop provides a unique combination of precision, skill development, and adaptability, making them indispensable tools for those dedicated to their craft.

Top 10 Manual Machines for Precision Work

Maintenance Tips for Manual Precision Machines

Maintaining manual precision machines is crucial for ensuring longevity and consistent performance in any workshop environment. Regular maintenance not only enhances the accuracy of these machines but also minimizes downtime caused by unexpected repairs. According to a report from the Precision Manufacturing Association, over 30% of maintenance issues stem from neglecting routine care. Workshops should develop a maintenance schedule that encompasses cleaning, lubrication, and calibration to prevent such issues. For example, ensuring that moving parts are well-lubricated reduces friction and wear, thereby extending the overall lifespan of these machines.

Additionally, keeping a detailed log of performance metrics can greatly assist in identifying potential issues before they escalate. A recent study showed that workshops that employ systematic tracking of their equipment's performance reduce failure rates by 25%. This proactive approach facilitates timely maintenance checks, allowing operators to address minor problems before they become significant obstacles. Furthermore, it is essential to train staff on proper operating procedures and routine maintenance checks to cultivate a culture of care and responsibility towards equipment, ultimately leading to a more efficient and sustainable workshop environment.

Top 10 Manual Machines for Precision Work: Essential Tools for Every Workshop

| Machine Type | Primary Use | Accuracy | Maintenance Frequency | Tips for Maintenance |

|---|---|---|---|---|

| Lathe Machine | Turning Operations | ±0.01 mm | Weekly | Lubricate moving parts, check alignment. |

| Milling Machine | Cutting Flat Surfaces | ±0.02 mm | Monthly | Check for wear, clean the table often. |

| Drill Press | Drilling Holes | ±0.01 mm | Bi-weekly | Ensure drill bits are sharp, clean chuck. |

| Band Saw | Cutting Curved Shapes | ±0.5 mm | Monthly | Check blade tension, inspect for damage. |

| Surface Grinder | Grinding Flat Surfaces | ±0.01 mm | Every usage | Keep coolant level adequate, clean magnetic chuck. |

| Tool and Cutter Grinder | Sharpening Tools | ±0.01 mm | Weekly | Inspect wheels for cracks, maintain spindle lubrication. |

| Tapping Machine | Creating Threads | ±0.05 mm | Monthly | Clean tapping area, check depth stops. |

| Bench Grinder | General Grinding | ±0.1 mm | Every usage | Check wheel balance, keep working area clean. |

| Scribe Tool | Marking Measurements | N/A | As needed | Keep the tip sharp, store in a protective case. |

Safety Guidelines for Using Manual Tools in Workshops

When working with manual tools in workshops, safety should be the foremost consideration. According to the Occupational Safety and Health Administration (OSHA), improper use of tools accounts for approximately 30% of workplace injuries annually. To mitigate these risks, it's essential for users to familiarize themselves with the tools they are using. This includes understanding the specific safety guidelines for each tool, such as the importance of wearing appropriate personal protective equipment (PPE), including goggles and gloves, which can reduce injury rates by up to 60%.

Moreover, a comprehensive safety training program can significantly enhance workshop safety. A report from the National Institute for Occupational Safety and Health (NIOSH) states that organizations implementing formal safety training see a 50% reduction in accident rates. Such programs emphasize the importance of proper tool handling practices, including regular inspections, maintenance checks, and the correct use of guards or safety devices on equipment. Workshops that incorporate these guidelines into their operations not only protect their workers but also foster a culture of safety that can lead to increased productivity and morale within the team.

Related Posts

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

-

10 Best Manual Machines for Efficient Work and Precision in Your Projects

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

-

How to Choose the Best Precision Machining and Manufacturing Services for Your Business Needs

-

The Future of Machine Manufacturing Innovations Transforming Industries

-

2025 How to Achieve High CNC Machining Precision in Manufacturing

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.